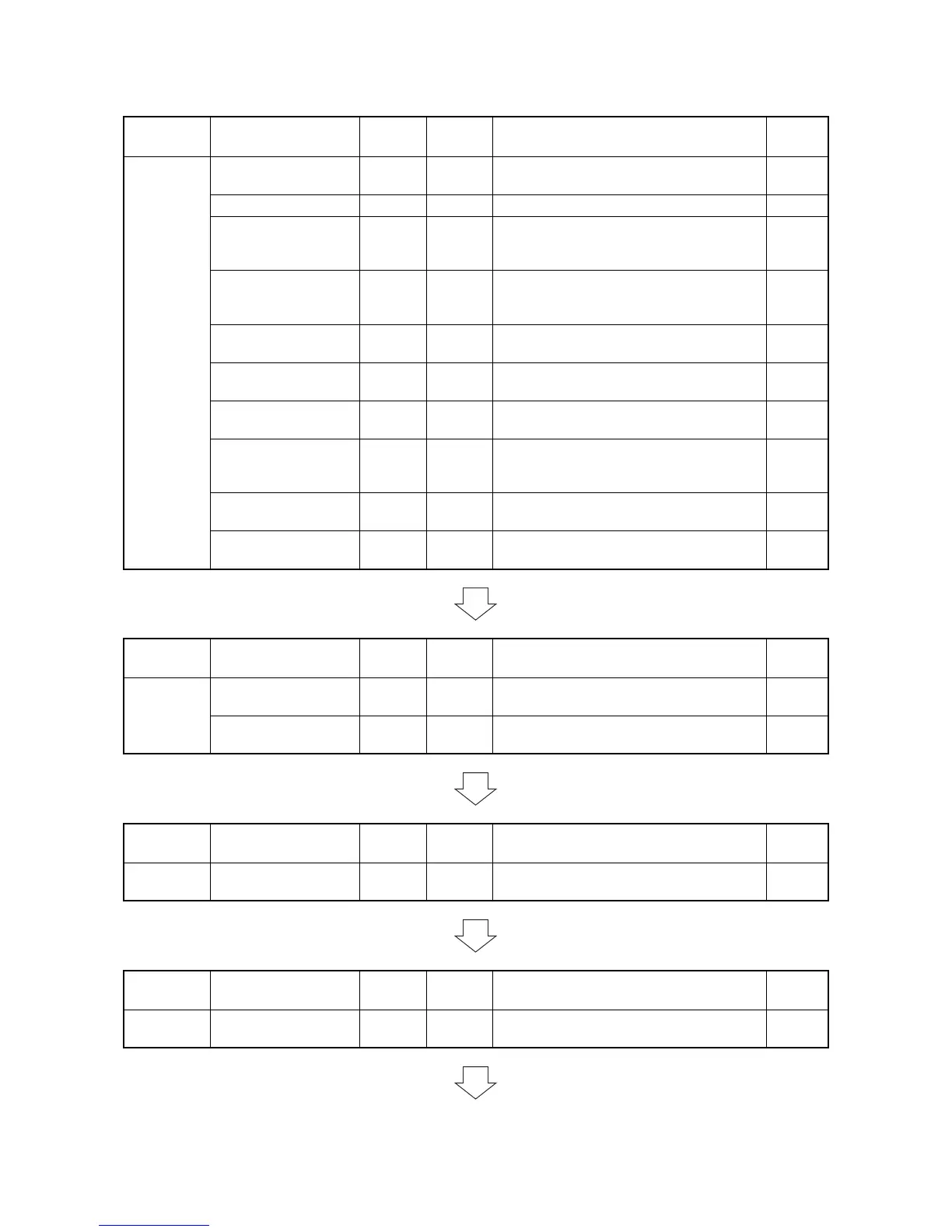

2KJ/2KH-2

2-4-3

Section

Maintenance

part/location

User call 150K Points and cautions Page

Optical

section

Slit glass Clean Clean Clean with a dry cloth or alcohol (do not clean

with a wet cloth).

Contact glass Clean Clean Clean with alcohol and then a dry cloth.

Mirror 1 Clean - Clean with a wet cloth and then a dry cloth

only if vertical black lines appear on the print

image.

Mirror 2 and mirror 3 Clean - Clean with a wet cloth and then a dry cloth

only if vertical black lines appear on the print

image.

Lens Clean - Clean with a dry cloth only if vertical black

lines appear on the print image.

Reflector Clean - Clean with a dry cloth only if vertical black

lines appear on the print image.

Exposure lamp Check

Replace

- Replace if an image problem occurs or after

the exposure lamp does not turn on.

P.1-5-24

Original size detection

sensor

Check

Clean

- Clean the sensor emitter and sensor receiver

with alcohol or a dry cloth only if there is a

problem.

Optical rail Check

Grease

- Check noise and shifting and then apply opti-

cal rail grease PG671 (P/N: 60170001).

Laser scanner unit Check

Clean

Clean Clean the slit glass with alcohol. P.1-5-35

Section

Maintenance

part/location

User call 150K Points and cautions Page

Transfer/

separation

section

Transfer roller Clean Clean Vacuum or clean with a dry cloth when user

call occurs.

P.1-5-45

Separation electrode Check

Clean

- Clean with a cleaning brush.

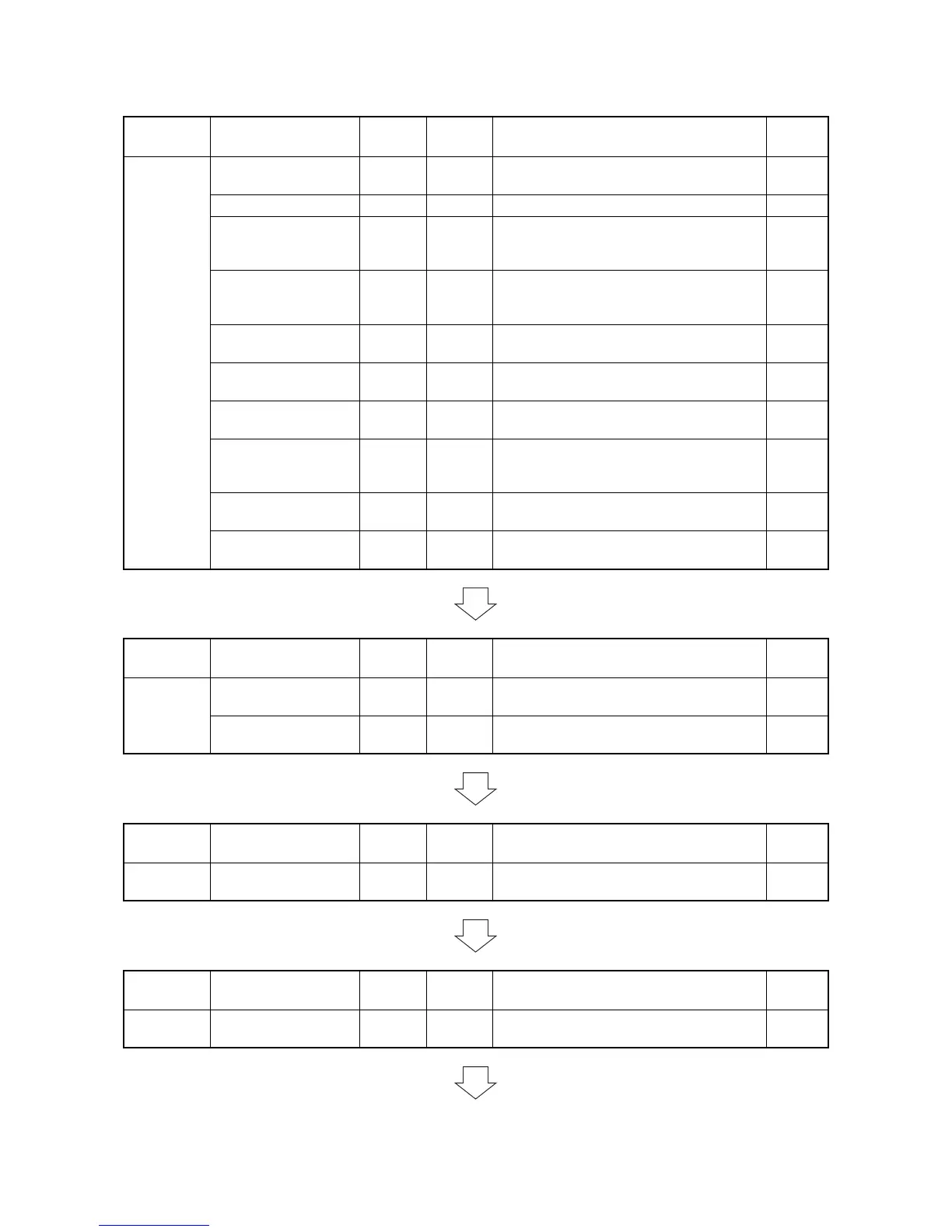

Section

Maintenance

part/location

User call 150K Points and cautions Page

Developing

section

Developing unit Check

Replace

- Replace if the problem occurs. P.1-5-44

Section

Maintenance

part/location

User call 150K Points and cautions Page

Drum section Drum unit Check

Replace

Replace Replace after feeding 150,000 sheets.

Replace if the problem occurs.

P.1-5-43

Loading...

Loading...