4-53

10.7 MAINTENANCE EVERY 1000 HOURS

Perform this maintenance in tandem with maintenance every 50/100/250/500 hours.

[1] REPLACEMENT OIL IN SWING MACHINERY CASE

The parts and oil are at high temperature immediately after the engine is stopped, and may

cause serious burns. Wait for the temperature to go down before starting the operation.

• For details of using oil specified, see “Maintenance 7.1 Use of Fuel, Coolant and Lubricants

According to Ambient Temperature”.

• After replacing oil, fully insert dipstick securely.

• Refill capacity: 2.5 liters

• Prepare a container to catch drain oil.

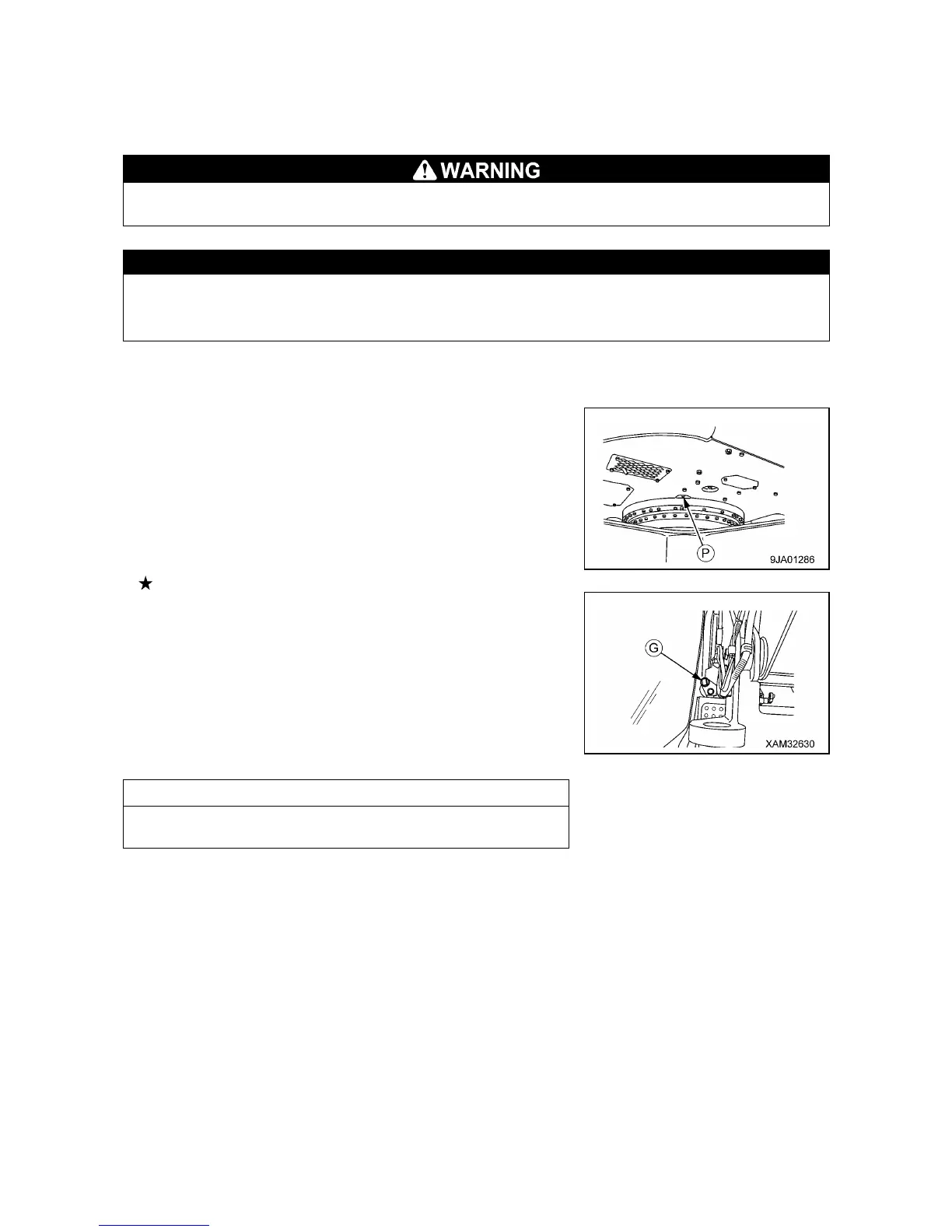

1. Swing the upper structure so that drain plug (P) is between the

left and right tracks.

2. Set a container under drain plug (P) at the bottom of the

machine.

3. Remove drain plug (P) at the bottom of the machine, drain the

oil.

4. After draining oil, tighten drain plug (P) securely.

Tightening torque: 44.1 to 93.1 Nm (4.5 to 9.5 kgfm)

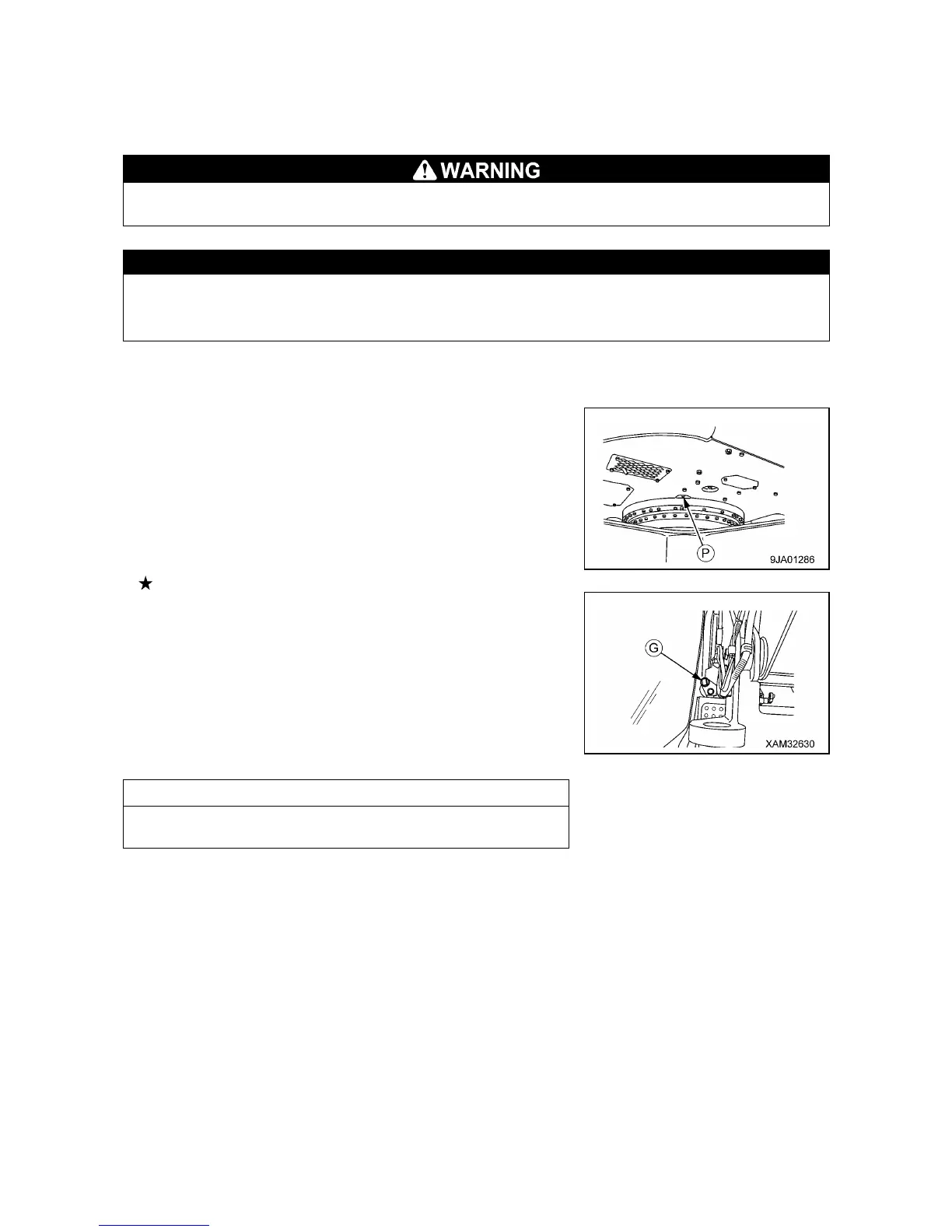

5. Remove dipstick (G) and add the specified amount of oil from

gauge guide hole.

6. Wipe off the oil on the dipstick (G) with a cloth.

7. Fully insert dipstick (G) into gauge guide, then remove it.

8. The oil level should be between the H and L marks on oil level

gauge (G).

9. If the oil level is below the L mark, add oil through gauge guide

hole.

The oil must be filled up to midway between the H and L marks

of the dipstick (G).

10. If the oil is above the H mark, drain the excess oil from drain

plug (P), then check the oil level again.

11. After adding, insert dipstick (G) into gauge guide securely.

Loading...

Loading...