4-60

10.8 MAINTENANCE EVERY 2000 HOURS

Perform this maintenance in tandem with maintenance every 50/100/250/500/1000 hours.

[1] CLEANING HYDRAULIC TANK STRAINER

• The parts and oil are at high temperature immediately after the engine is stopped, and may

cause serious burns. Wait for the temperature to go down before starting the operation.

• When removing the oil filler cap, turn it slowly to release the internal pressure, then remove it.

• For details of using oil specified, see “Maintenance 7.1 Use of Fuel, Coolant and Lubricants

According to Ambient Temperature”.

• The engine must be at a halt until piping and hydraulic equipment is filled with oil after

replacement of the hydraulic oil filter.

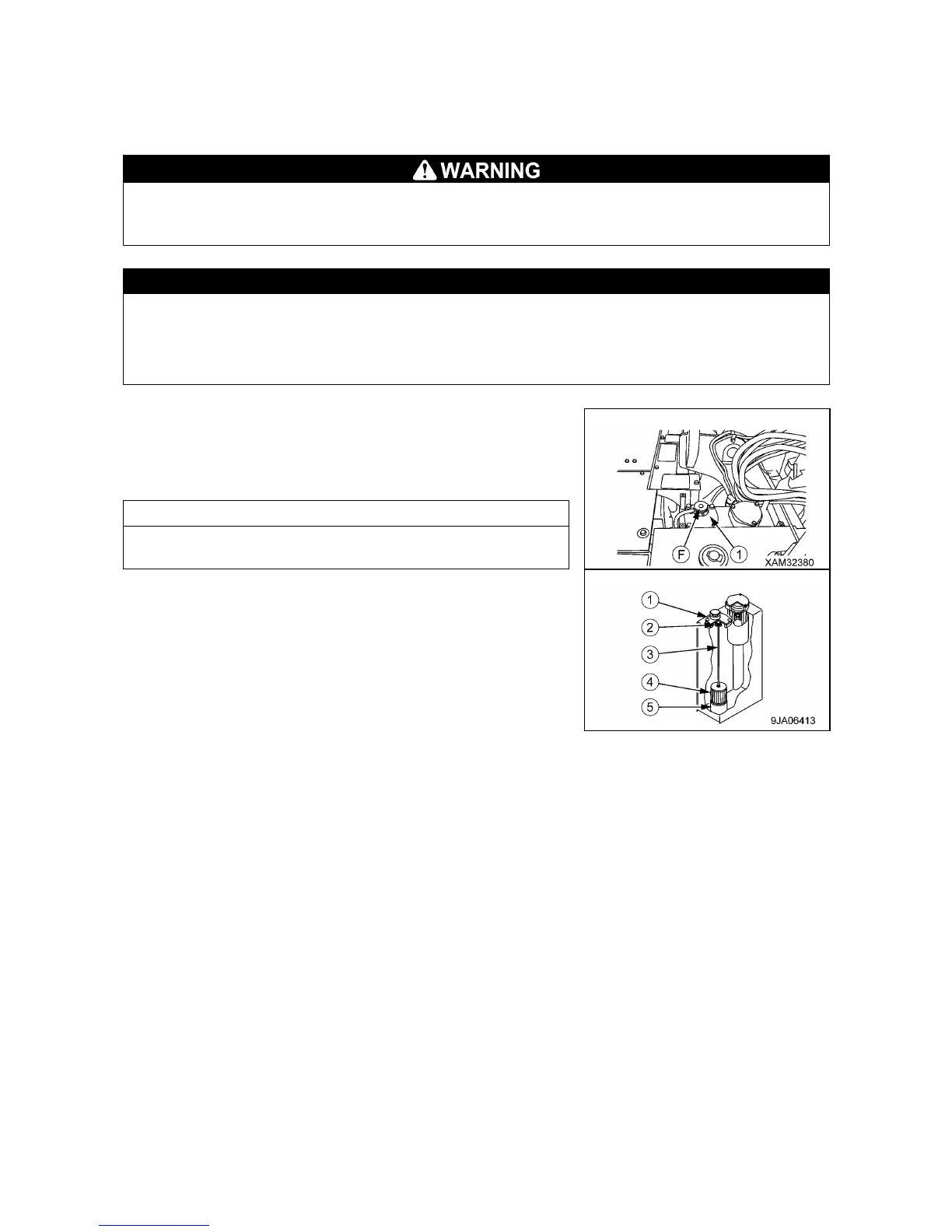

1. Remove the cover at the top of the hydraulic tank.

2. Remove the cap (F) from oil filler, and release the internal

pressure.

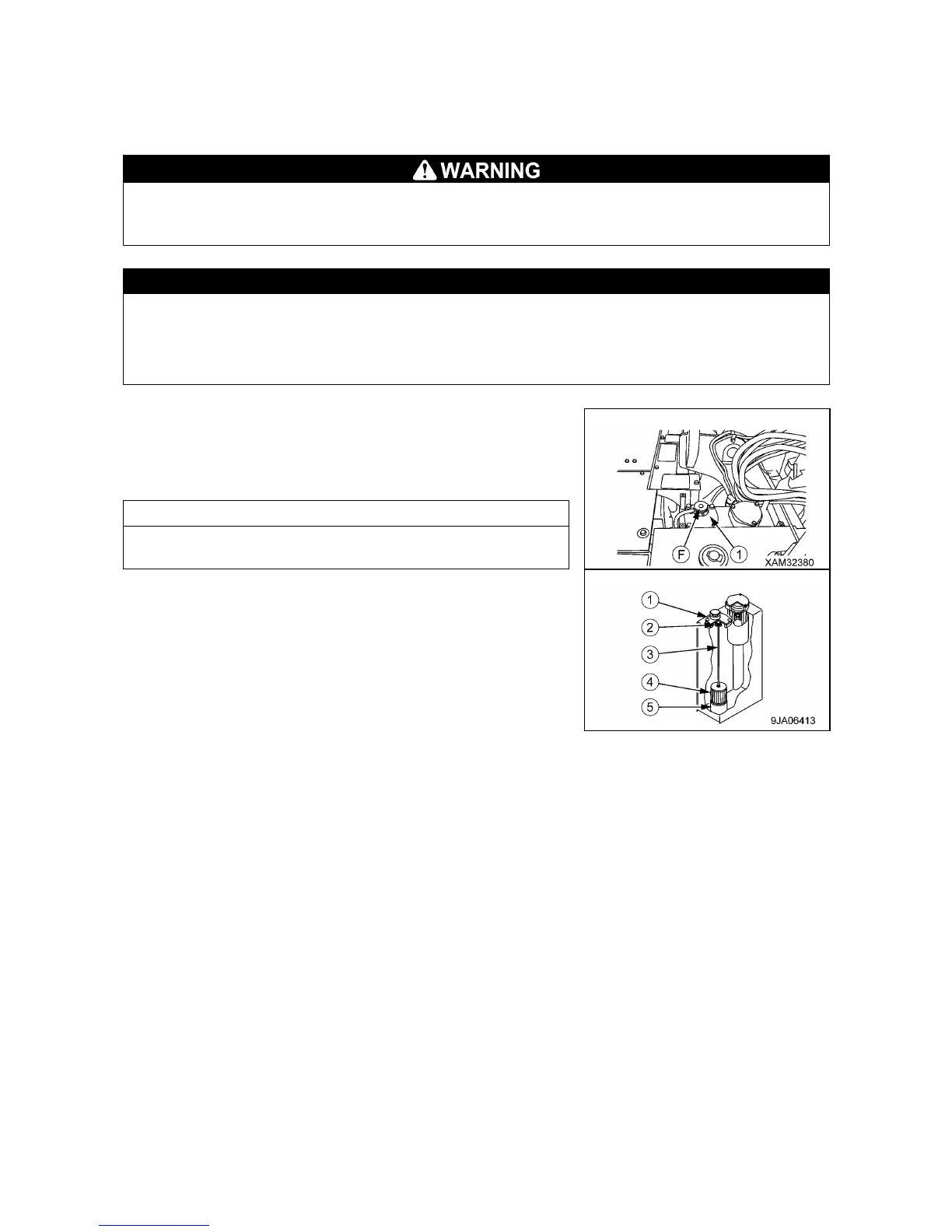

3. Remove 4 bolts, and then remove cover (1).

When doing this, the cover may fly out under the force of spring

(2), so hold the cover down when removing the bolts.

4.Hold the top of rod (3) and pull up to remove spring (2) and

strainer (4).

5. Remove any dirt stuck to strainer (4), and then wash it in

flushing oil. If strainer (4) is damaged, replace it with a new part.

6. When installing, insert strainer (4) into protruding part (5) of the

tank, and assemble.

7. Install cover (1) with bolts.

8. Install the oil filler cap (F) at the top of the hydraulic tank.

9. Install the cover at the top of the hydraulic tank.

[2] CHECKING ALTERNATOR AND STARTER MOTOR

The brushes may be worn or the bearing may have run out of grease, contact us or our sales service

agency for inspection and repairs.

If the engine is started frequently, have this inspection carried out every 1000 hours.

[3] CHECKING/ADJUSTING ENGINE VALVE CLEARANCE

Special tools are needed for inspection and maintenance, please contact us or our sales service agency.

Loading...

Loading...