ELECTRIC SYSTEM 16000 SERVICE/MAINTENANCE MANUAL

3-4

Published 05-03-17, Control # 228-03

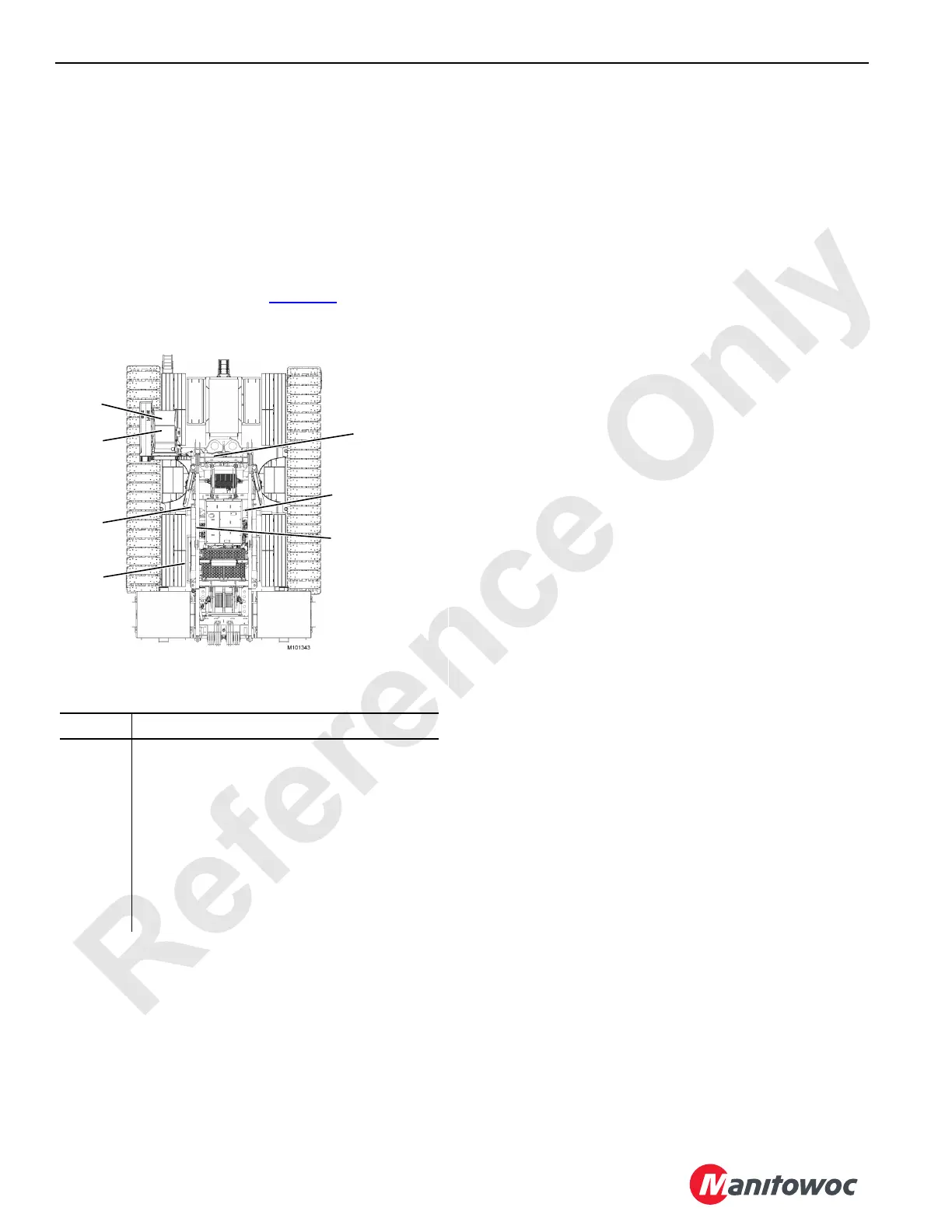

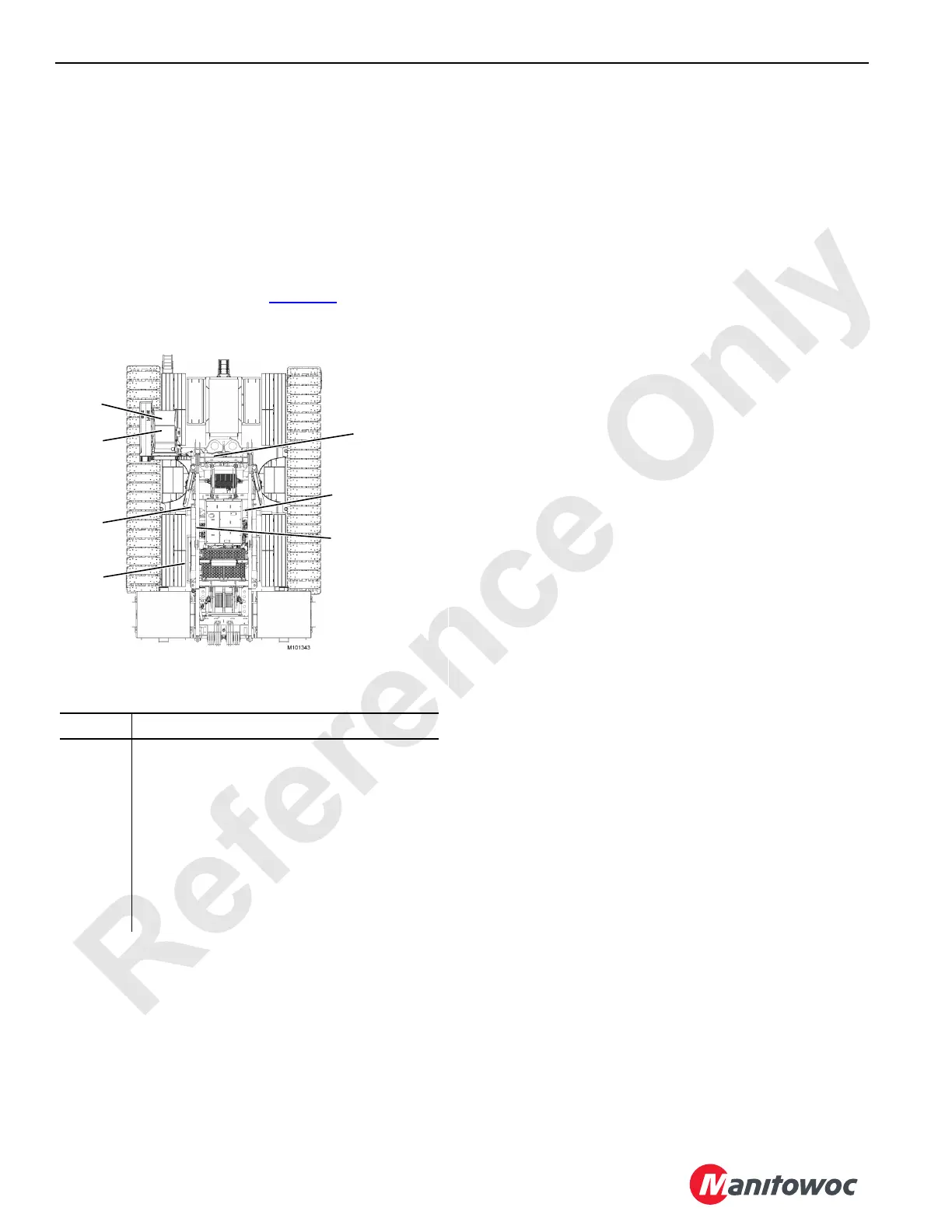

TEST VOLTAGES

The Model 16000 operating system uses the EPIC

®

system

with CAN Bus

®

technology. The CAN Bus system uses

multiple nodes containing controllers that communicate with

the node 1 (master) controller by sending data packets over

a two-wire bus line. The data packets are tagged with

addresses that identify the system components of each

node.

This section contains test voltages sorted by the nodes. The

nodes are listed and identified in Figure 3-3

.

Node Table Heading Descriptions

The CAN tables on the following pages provide information

found on the crane’s electrical schematics at the end of this

section.

Interpret the connector codes using the following example

for code 34-R:

• The number 34 is the cable number:

- The number 3 is the node number.

- The number 4 is the receptacle number where the

item is located on the node.

• The last character R is the receptacle pin number.

The Function Type indicates the type of connection, such as

power, ground, signal, analog input (AI), digital input (DI), or

digital output (DO).

The Receptacle/Pin No. (Engine Node-0 only) indicates the

input-to-receptacle number and pin number code.

The Wire No. (Engine Node-0 only) indicates the wire-to-

computer receptacle or wire number code.

The CAN Packet Number indicates the location of items for

all nodes except node 0, which does not have CAN packet

numbers. For example, interpret CAN Packet Number

CAN129-3-4 (Drum 1 Park Switch) using the following:

• CAN129 is the packet location number.

• Number 3 is the bank where information is stored.

• Number 4 is the identifier for that item.

Node Description

1 Master (Front Console)

2 Handles and Cab Controls

3 Drum Pump, Alarms, Sensors, and Accessories

4 Pressure Senders, Drum 4, and Accessories

5 Drum 2, Sensors, and Auto Lubrication

6 Drum Brakes, Pawls, and Sensors

7MAX-ER

0 Engine

FIGURE 3-3

1

2

3

4

5

0

In Boom Butt

(without MAX-ER)

7

On MAX-ER

Front Rotating Bed

(with MAX-ER)

6

Loading...

Loading...