Manitowoc Published 05-03-17, Control # 228-03 2-7

16000 SERVICE/MAINTENANCE MANUAL HYDRAULIC SYSTEM

5. Twist the element handle counter-clockwise and pull the

filter element out of the body. Discard the element.

Do not attempt to clean or reuse the element.

Do not operate the crane without the return filter

elements installed.

6. Lubricate the o-ring at both ends of the new element with

clean hydraulic oil and securely install the element over

the stem in the housing.

7. If necessary, replace the o-ring in the filter cover.

8. Reinstall and securely tighten the filter cover.

9. Start the engine and allow the hydraulic system to return

to normal operating pressure and temperature. Check

the filter cover and vent plug for leaks. Securely tighten

the filter cover and vent plug as required.

10. Stop the engine, check the tank level, and refill the tank

as required.

11. Reinstall the two covers over the hydraulic tank.

Changing Oil

See Figure 2-1 for the following procedure.

Drain and refill the hydraulic system every 1,000 hours or

semiannually, whichever comes first, unless an alternate

interval has been established through an oil analysis

program:

1. Operate the crane until the hydraulic oil is at the normal

operating temperature. This will help prevent impurities

from settling in the system.

2. Make sure the crane is level.

3. Stop the engine.

4. Remove the cover above the hydraulic tank.

5. Remove the manual fill plug (2a).

6. Open the drain valve (8) and drain the tank completely

into a suitable container.

7. Clean all dirt from the access cover in the underside of

the tank and remove the cover. Keep dust and dirt

from entering the tank while covers are off.

8. Flush out any sediment inside the tank.

9. Carefully inspect the suction filters (strainers, inside the

tank) for damaged or clogged holes and for sludge, gum

or lacquer formation. If necessary, clean the filters:

a. Remove the access cover from the side of the tank.

b. Inspect the cover gasket and replace it if it is

damaged.

c. Remove the filter (strainers) from inside the tank.

d. Soak the filter in clean, nonflammable solvent.

Brush off the outer surface, and flush the filter from

the inside out. Discard the filter if it is damaged.

e. Securely reinstall the filter.

f. Re-install the access cover on the side of the tank.

10. Using a new o-ring, secure the access cover to the

underside of the tank.

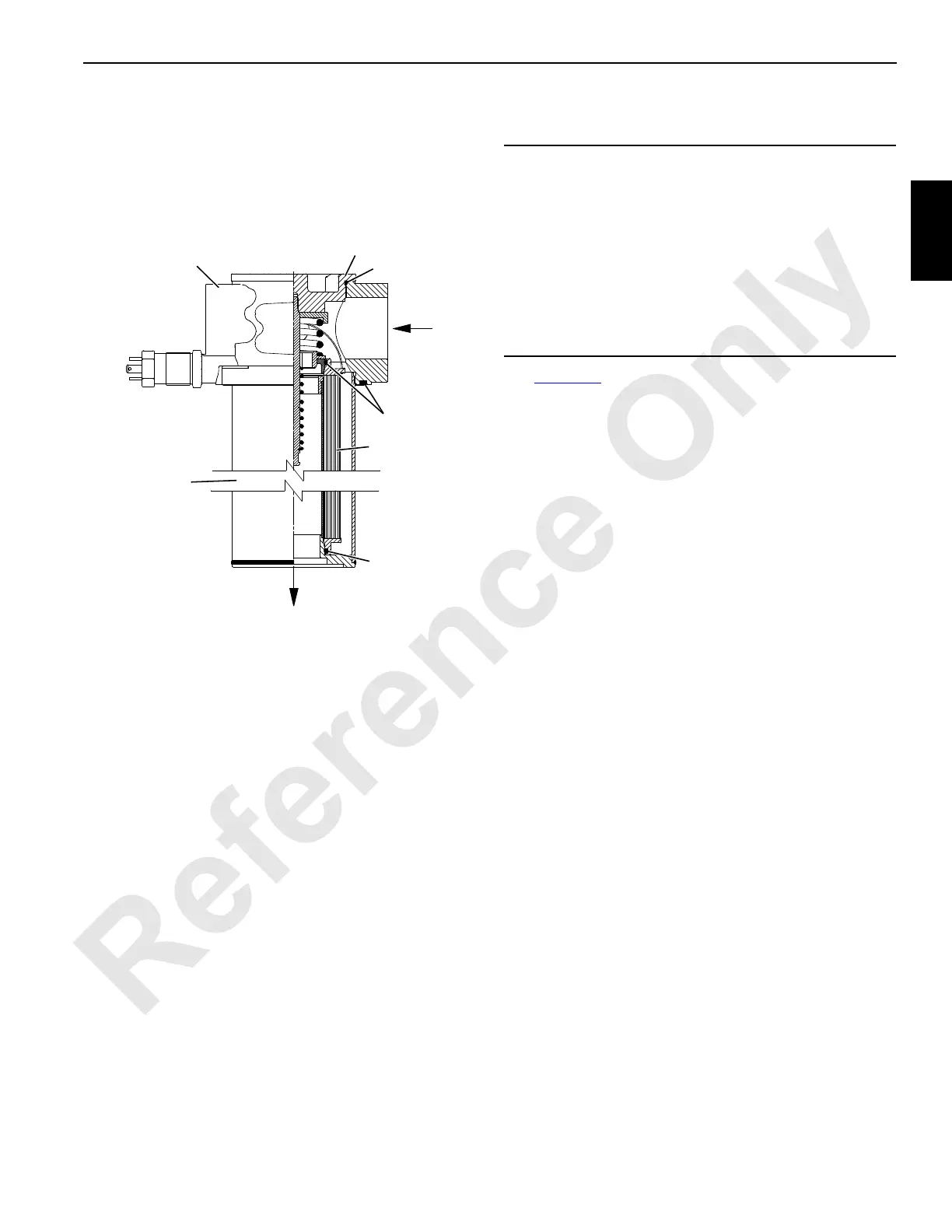

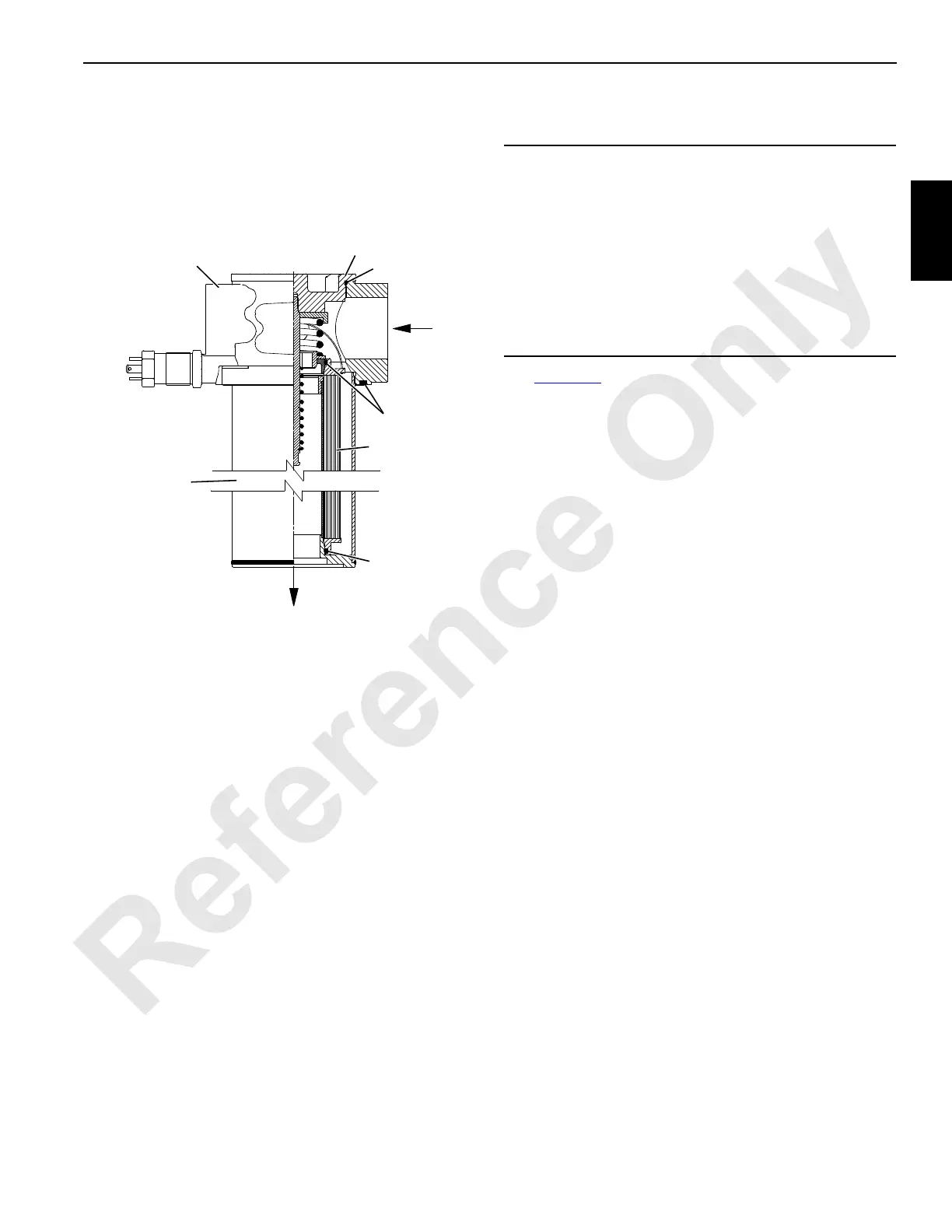

FIGURE 2-5

A00651

Cover

Element

Inlet

Body

O-Ring

O-Rings

Head

O-Ring

Outlet

to Tank

CAUTION

In the Event of a Catastrophic Failure of a

Hydraulic Component

Contact your Manitowoc dealer or the Crane Care Lattice

Team if the crane’s hydraulic system has experienced a

catastrophic failure. To avoid additional damage, the

process of removing debris and contaminants must be

guided or performed by experienced crane technicians.

For general instructions following a catastrophic failure,

see Manitowoc Service Bulletin W007-009.

Loading...

Loading...