HOISTS 16000 SERVICE/MAINTENANCE MANUAL

5-14

Published 05-03-17, Control # 228-03

SHEAVE, ROLLER, AND DRUM INSPECTION

Perform the following inspections weekly:

1. Check the drum clutches and brakes for proper

adjustment.

2. Check all sheaves, rollers, and drums for the following

conditions:

- Unusual noises

- Freedom of movement—must turn freely by hand.

The rope may have to be loosened to perform this

inspection.

- Wobble (the sheave, roller, or drum must turn true

with very little side-to-side or up-and-down play)

- Signs of rust, which indicate that water may have

entered the bearing

- Grease leaks, which indicate a faulty seal or water

in the grease

The above problems indicate bearing damage. If found,

the corresponding sheave, roller, or drum should be

disassembled for further inspection. New bearings

should be installed.

For sheaves not equipped with grease fittings, be sure to

pack new bearings with grease at assembly.

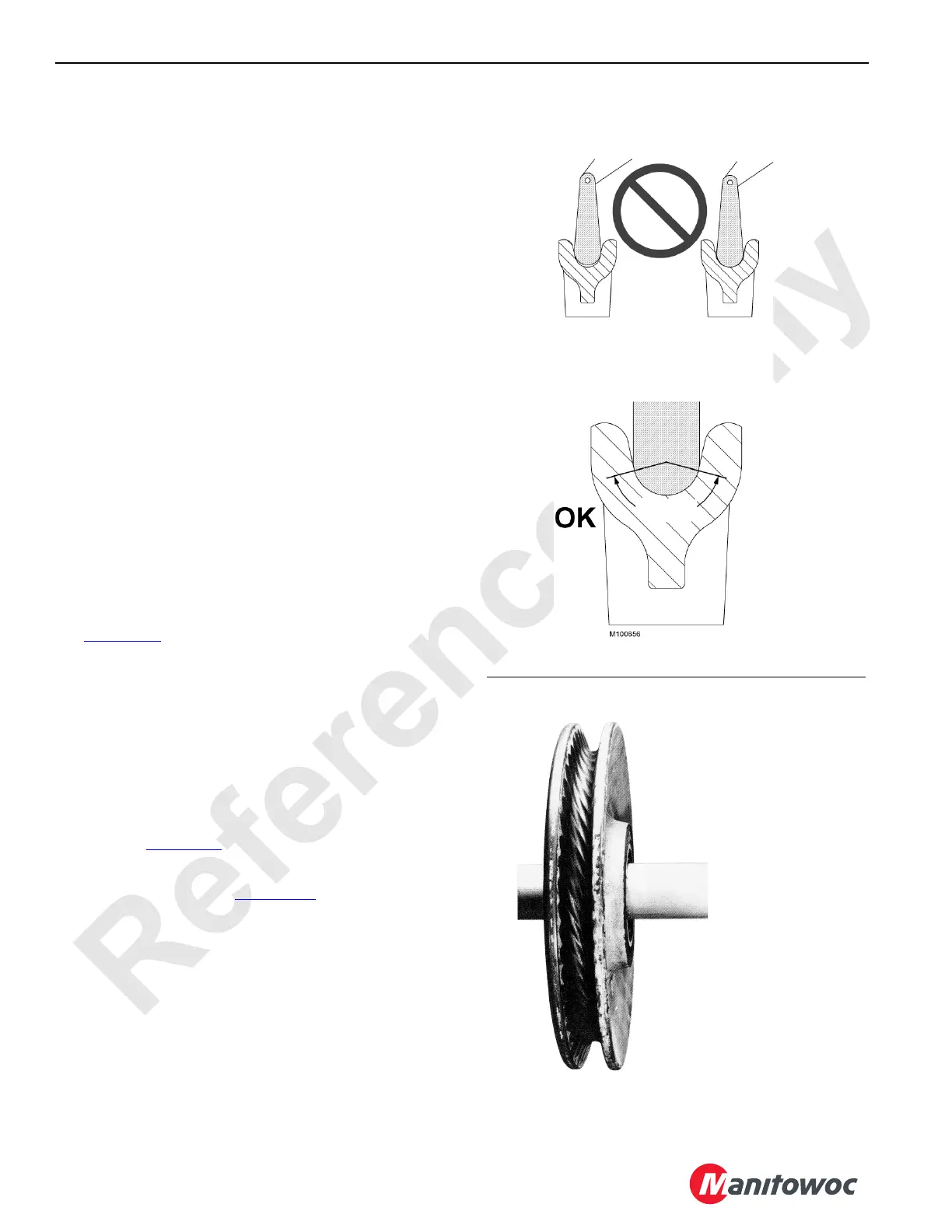

3. For steel sheaves, check the depth, width, and contour

of each sheave using a groove gauge as shown in

Figure 5-10

. Replace sheaves that have over or under

sized grooves.

4. Replace grooved drums that allow one wrap of wire rope

to contact the next wrap as rope spools onto the drum.

5. Inspect sheaves to verify they do not contact another

sheave or structural plate work. There should be uniform

clearance between sheaves in a cluster. Repair or

replace worn or damaged sheaves.

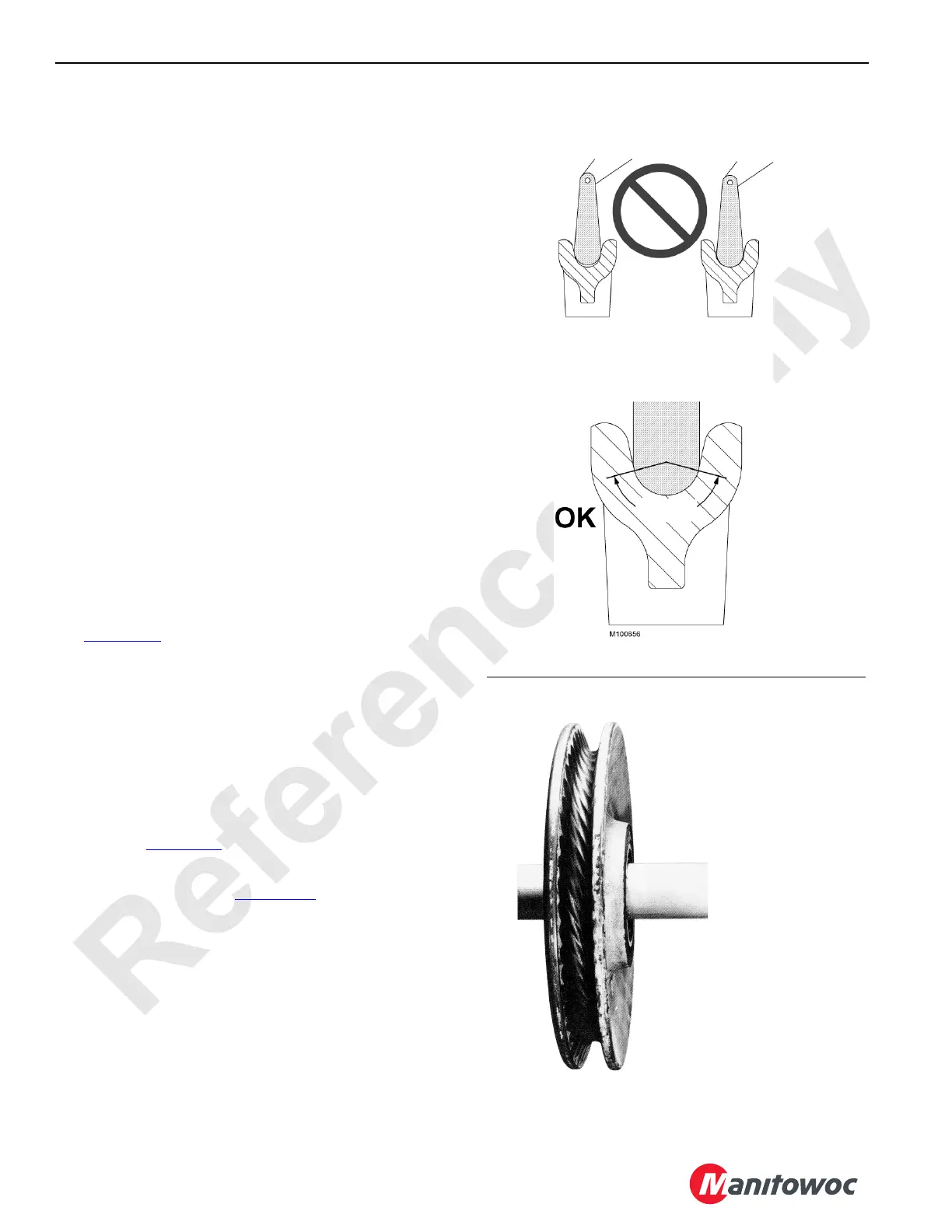

6. Remachine or replace steel sheaves, drums, or rollers

that have been corrugated by the wire rope’s print as

shown in Figure 5-11

.

7. Inspect nylon sheaves for excessive tread diameter

wear at location E in Figure 5-14

. Measure at three

places to check for uneven wear.

Wear must not exceed the limits given in the table.

Replace worn or damaged sheaves.

FIGURE 5-10

Observe groove to see if contour of gauge

matches contour at bottom of sheave groove.

Proper fitting sheave groove should support wire

rope or 135–150° of rope circumference.

Groove Too Small

Groove Too Large

135°–150°

FIGURE 5-11

“Corrugated” steel sheave,

roller, or drum will cause

wire rope to wear rapidly.

Loading...

Loading...