Manitowoc Published 05-03-17, Control # 228-03 2-25

16000 SERVICE/MAINTENANCE MANUAL HYDRAULIC SYSTEM

Charge Pressure Test

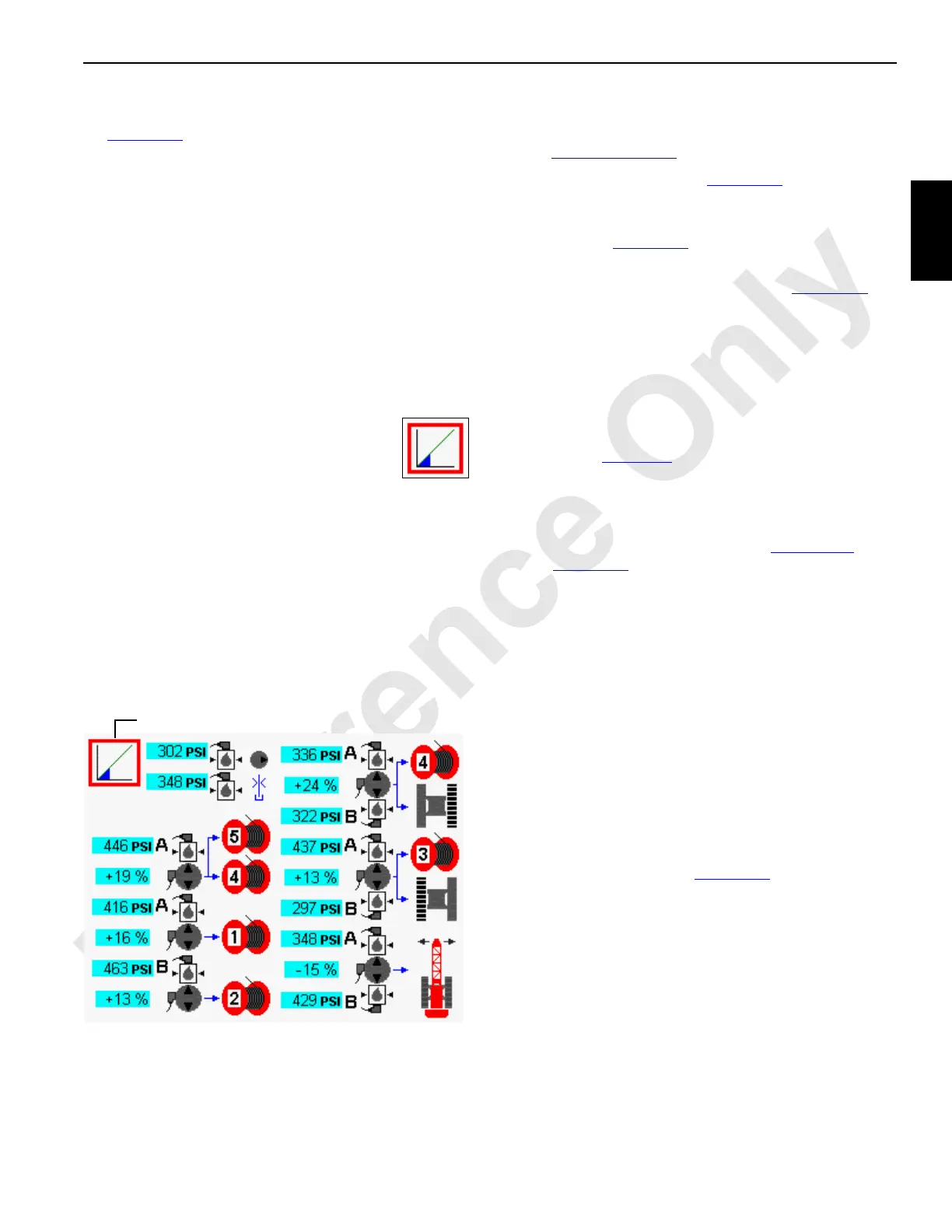

See Figure 2-22 for the following procedure.

The charge pressure test checks the ability of all primary

crane functions to build proper charge pressure. This test

generally is used only as a shop procedure on new cranes. It

can also be used as a quick way to test hydraulic

components in the primary hydraulic circuits. Charge pump

pressure must be within 19 to 27 bar (276 to 392 psi).

Test charge pressure using the following procedure:

1. Apply all the park brakes with the switches on the control

console.

2. Start and run the engine at low idle.

3. Press the Enter button to go to the Pressure Test and

Calibration screen from the Menu screen.

4. Press the Enter button to go to level 2. Use

the Select buttons to show the LOW

PRESSURE icon in the data box.

5. Press the Confirm button to start the test.

6. The test starts and the percent of completion is

displayed in the data box.

7. When the test is complete, the charge pressure icon

reappears in the data box.

Charge pressure levels must be within a specified range

during this test. Any pump that failed to maintain charge

pressure within a specified range is highlighted in yellow.

Troubleshoot the failed circuit to determine the cause of

fault.

High Pressure Adjustment

The following adjustment is only required when a system

fails the High Pressure Test

.

Unless otherwise specified, see Figure 2-23

for the following

procedure:

1. Scroll to the diagnostic screen for the corresponding

function (see Figure 2-24

).

2. Disconnect the electrical connector from the

corresponding brake solenoid valve (see Figure 2-12

).

3. With the engine running at low idle, slowly move the

desired control handle:

• In either direction from off for swing or travel

• Back from off (hoist direction) for all drums

4. Do not demand any more than 20% handle command.

5. Pressure on the screen should indicate the pressure

specified in Table 2-10

.

6. If the proper pressure is not indicated, adjust the

corresponding multi-function valve:

a. Remove the protective cap (3) from the multi-

function valve (1 or 2). See Table 2-10

and

Figure 2-17

for pump port identification.

b. Loosen the lock nut (4)

DO NOT tamper with the bypass hex (6). See the

pump manufacturer’s instructions.

c. Using an internal hex wrench, adjust the multi-

function valve adjusting screw (5):

- Turn IN to increase the pressure

- Turn OUT to decrease the pressure

7. Repeat step 6 until the specified pressure is indicated.

8. Hold the adjusting screw (5) in position and securely

tighten the lock nut (4).

9. Install the protective cap (3).

10. Reconnect the electrical connector to the corresponding

brake solenoid valve (see Figure 2-12

).

FIGURE 2-22

D16-29B

Data Box

Loading...

Loading...