HOISTS 16000 SERVICE/MAINTENANCE MANUAL

5-18

Published 05-03-17, Control # 228-03

LOAD BLOCK AND HOOK-AND-WEIGHT

BALL INSPECTION

The operating condition of the load block and the hook-and-

weight ball can change daily with use. Therefore, they must

be inspected daily (at the start of each shift) and observed

during operation for any defects that could affect their safe

operation. Correct all defects before using the load block or

the hook-and-weight ball.

Daily inspection and maintenance will include the following

points (see Figure 5-16

and Figure 5-17):

1. Clean the load block or hook-and-weight ball.

2. Lubricate the sheaves (if the fittings are provided), hook

trunnion, hook swivel, and any other part equipped with

a grease fitting at the intervals specified in the

Lubrication Guide.

WARNING

Falling Load Hazard!

To prevent a load from dropping due to structural failure of

the load block or hook-and-weight ball, use the following

precautions:

• Only use a load block or a hook-and-weight ball

which has a capacity greater than or equal to the load

to be handled.

• Do not remove or deface the nameplate (Figure 5-15

)

attached to load blocks and hook-and-weight balls.

• See the Duplex Hook topic in Section 4 of Operator

Manual for recommended sling angles and capacity

restrictions when the load block has a duplex or

quadruplex hook.

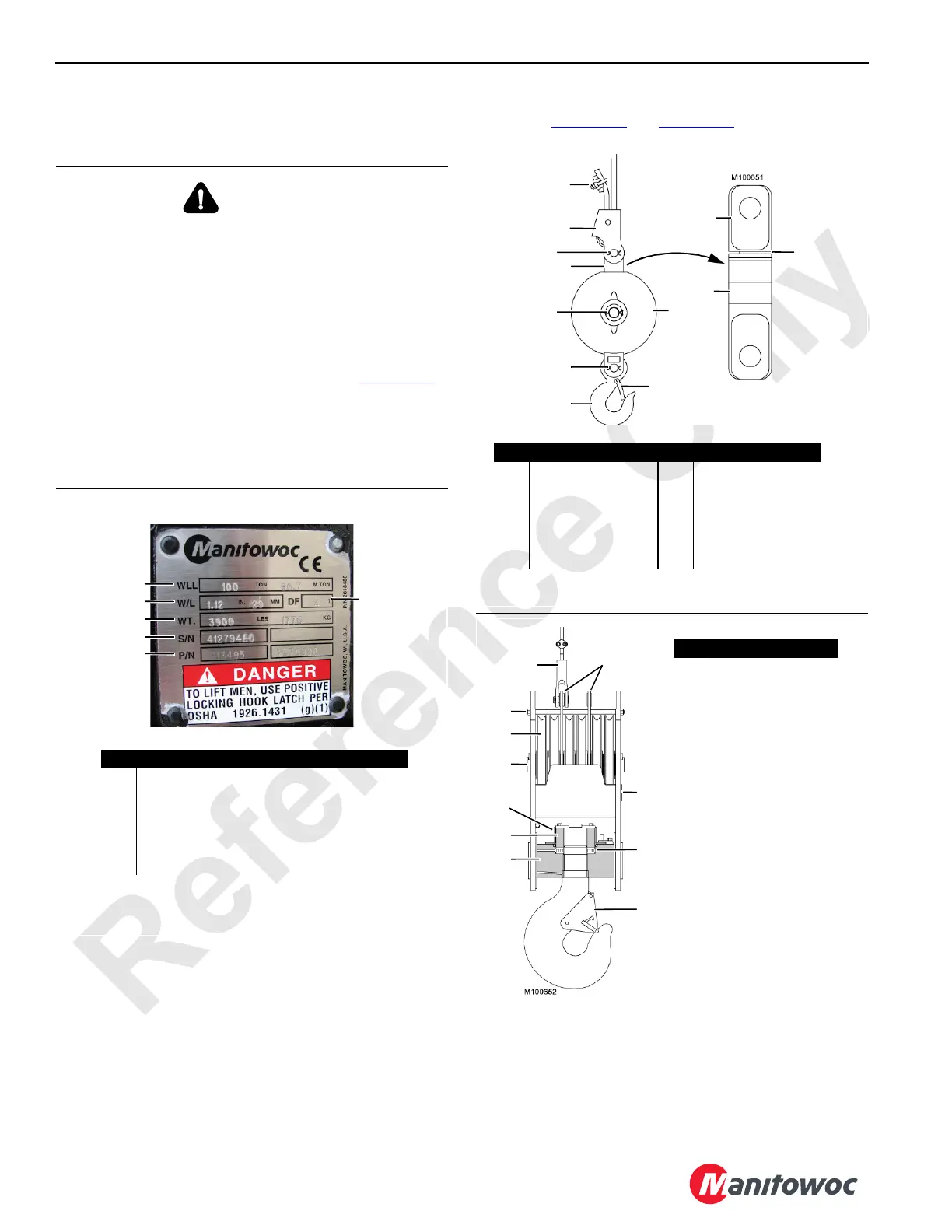

FIGURE 5-15

1

2

3

4

5

6

Item Description

1 Working Load Limit (US and metric ton)

2 Wire Rope Diameter (in and mm)

3 Block Weight (lb and kg)

4 Block Serial Number

5 Block Part Number (OEM and Manitowoc)

6 Design Factor

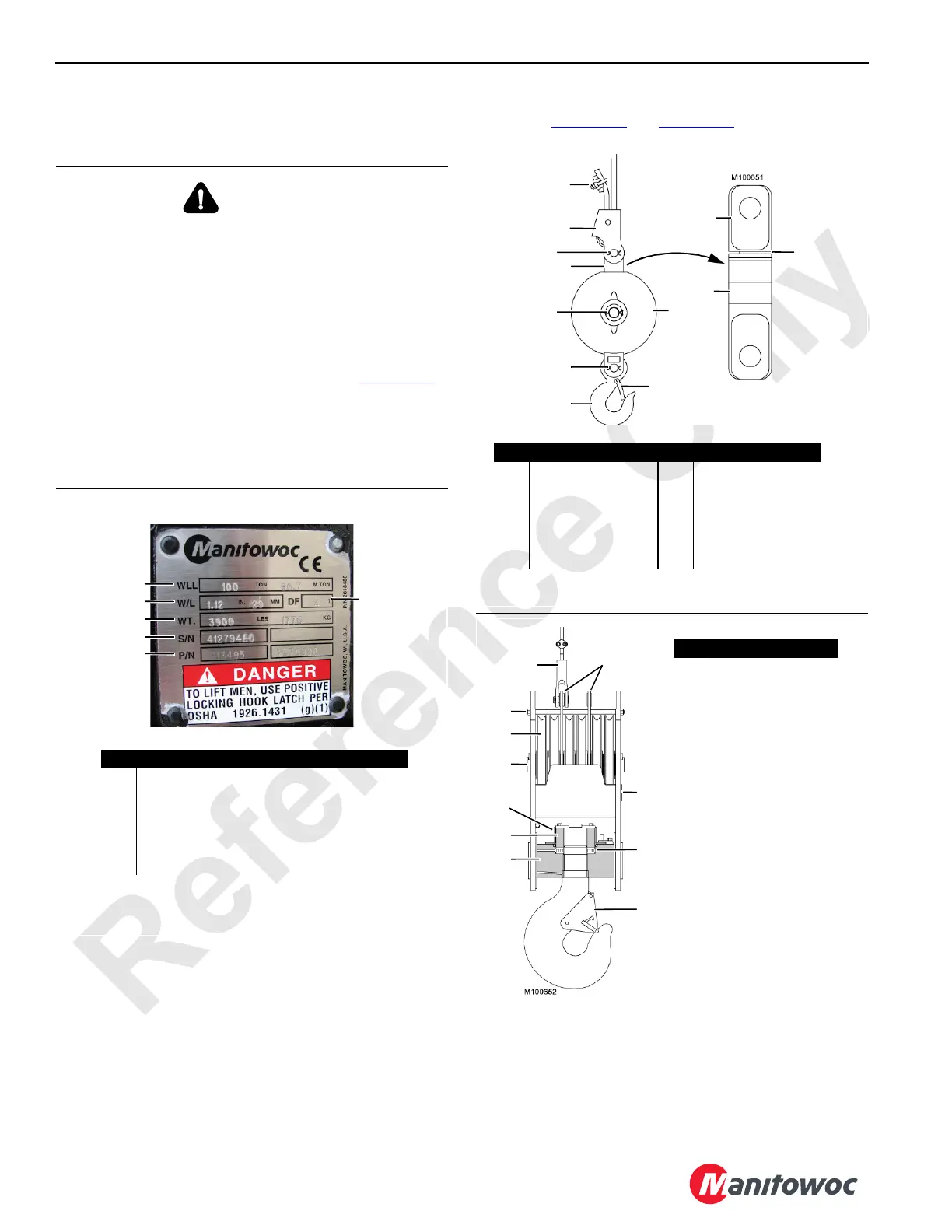

FIGURE 5-16

Item Description Item Description

1 Dead-End Clip 4c Check Gap Here

2 Socket and Wedge 5 Bolt or Pin

3 Bolt or Pin 6 Weight Ball

4 Swivel 7 Bolt or Pin

4a Swivel Shank 8 Hook

4b Swivel Barrel 9 Latch

1

2

4

3

5

6

4b

4a

4c

7

8

9

FIGURE 5-17

Item Description

1 Socket and Wedge

2 Center Plates

3 Tie Bolt

4 Sheaves

5 Sheave Shaft

6 Name Plate

7 Locking Cap

8Hook Nut

9 Trunnion

10 Thrust Bearing

11 Latch

12 Hook

1

3

4

5

7

8

9

10

6

11

2

Loading...

Loading...