Manitowoc Published 05-03-17, Control # 228-03 2-27

16000 SERVICE/MAINTENANCE MANUAL HYDRAULIC SYSTEM

Charge Pressure Adjustment

The following adjustment is only required when a system

fails the Charge Pressure Test

.

1. Scroll to the diagnostic screen for the corresponding

function (see Figure 2-24

).

2. Start and the run engine at high idle. With the function in

neutral, the system pressure on the diagnostic screen

should read 22 to 26 bar (319 to 377 psi).

3. If the specified pressure is not indicated, stop the engine

and connect an accurate 0 to 69 bar (0 to 1,001 psi)

hydraulic pressure gauge to the coupler at the

corresponding pressure sender (see Figure 2-30

).

4. Repeat step 2. If the specified pressure is still not

indicated:

• Perform a Pressure Sender Test

. Replace the faulty

pressure sender if needed

• Perform a Control Calibration

If the specified pressure is still not indicated, take the

following actions:

• If pressure is too high, check that the pump neutral

is adjusted properly. If the pressure is still high,

adjust the charge pressure relief valve.

• If pressure is too high, adjust the charge pressure

relief valve. If you cannot raise the charge pressure,

excessive system leakage is indicated.

5. To adjust the charge pressure:

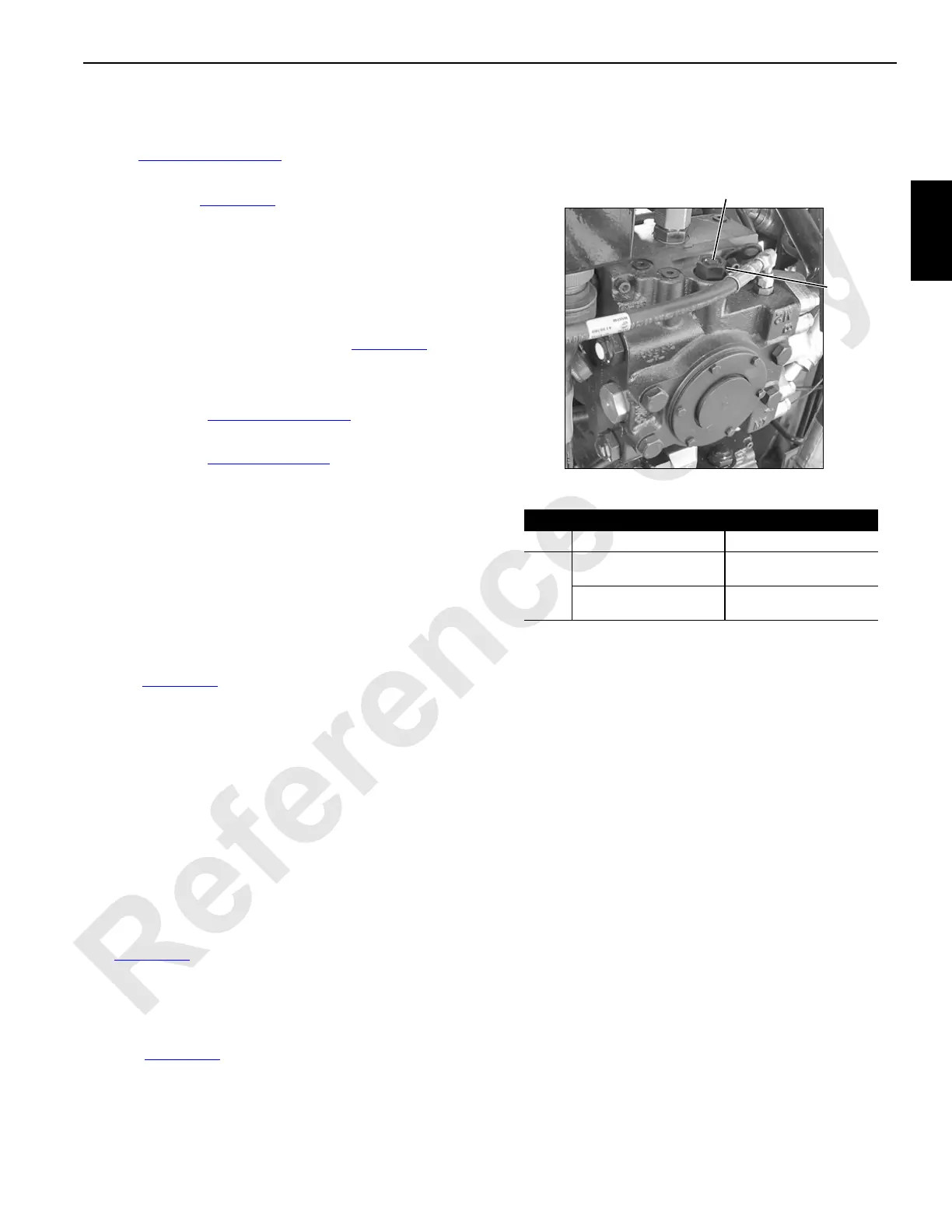

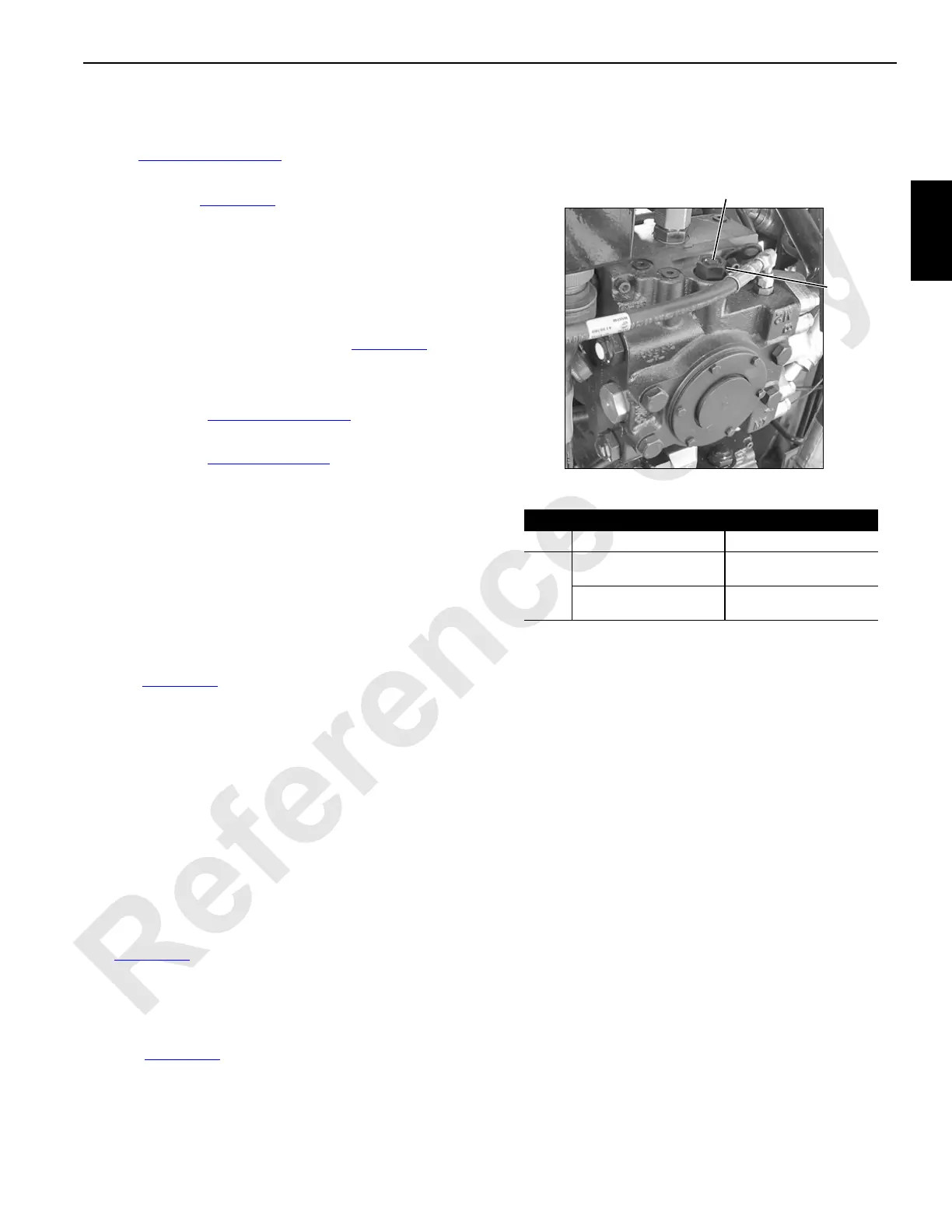

See Figure 2-25

for the following procedure:

a. Loosen the lock nut (1).

b. Adjust the adjusting plug (2):

- Turn IN to increase the pressure

- Turn OUT to decrease the pressure

c. Once the specified pressure is indicated, hold the

adjusting plug (2) in position and securely tighten

the lock nut (1).

6. Stop the engine and remove the gauge from the

transducer gauge port.

Pump Neutral Adjustment

See Figure 2-26 for the following procedure.

To adjust pump neutral:

1. Park all the crane functions and stop the engine.

2. Disconnect the electrical connector from the pump EDC

(see Figure 2-29

).

3. Install an accurate 0 to 69 bar (0 to 1,001 psi) hydraulic

pressure gauge in each servo gauge port (1).

4. Start and run the engine at high idle.

5. Loosen the lock nut (2).

6. Using an internal hex wrench, turn the adjusting screw

(3) IN until the pressure increase in either gauge.

7. Note the angular position of internal hex wrench.

8. Then, turn the adjusting screw OUT until pressure

increases an equal amount in the other gauge.

9. Again, note the angular position of the internal hex

wrench.

10. Turn the adjusting screw in half the distance between

the positions noted above.

11. The pump control should now be in neutral with both

gauges reading the same pressure.

12. Hold the adjusting screw (3) in position and securely

tighten the lock nut (2).

13. Stop the engine, remove the gauges, and securely

install the servo gauge port plugs (1).

Item Description Hex Wrench Size

1 Lock Nut 12,7 mm (1/2 in)

2

Adjusting Plug

Series 030-100

27 mm (1-1/16 in)

Adjusting Plug

Series 030-100

41,3 mm (1-5/8 in)

1

P1600a

FIGURE 2-25

2

Typical Pump Installation

Loading...

Loading...