INTRODUCTION 16000 SERVICE/MAINTENANCE MANUAL

1-40

Published 05-03-17, Control # 228-03

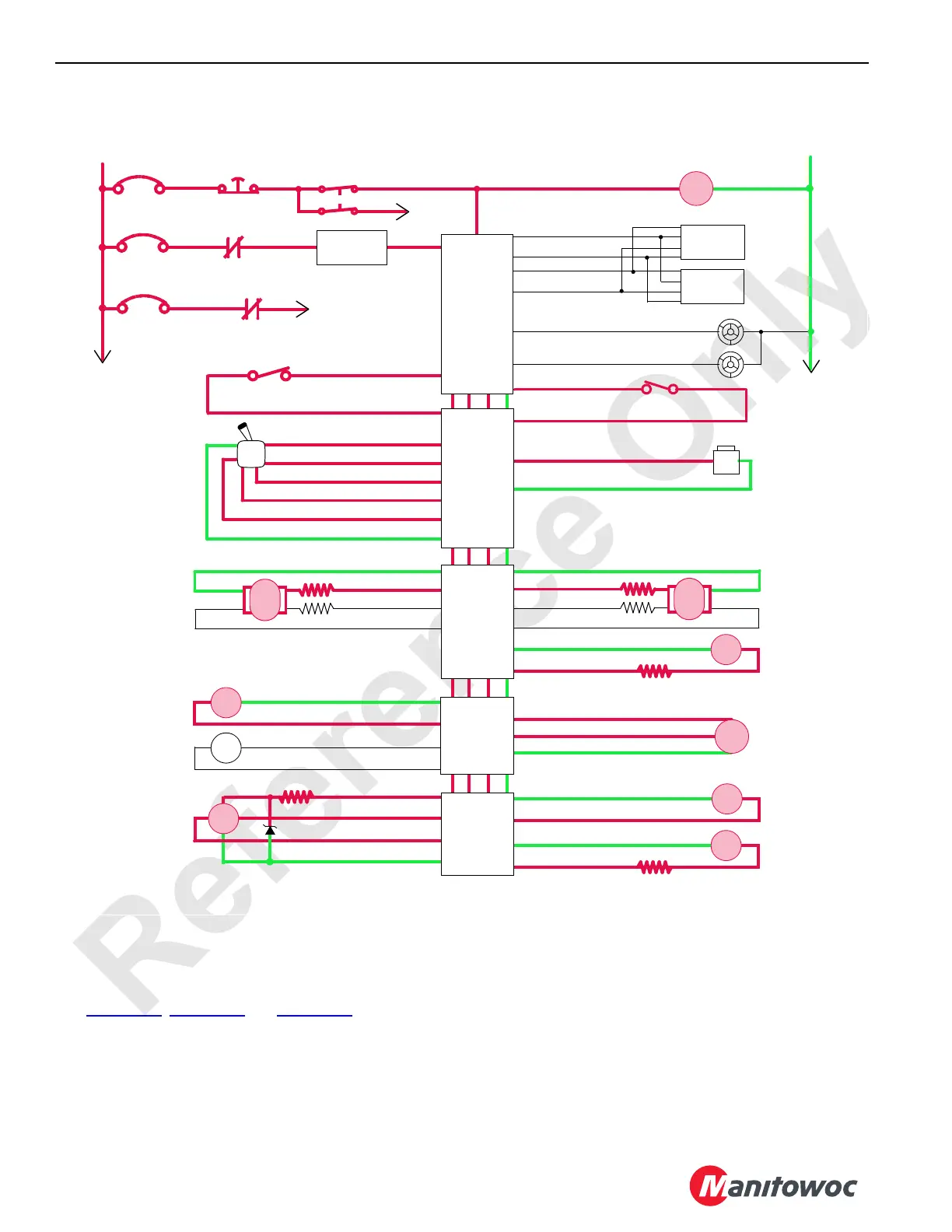

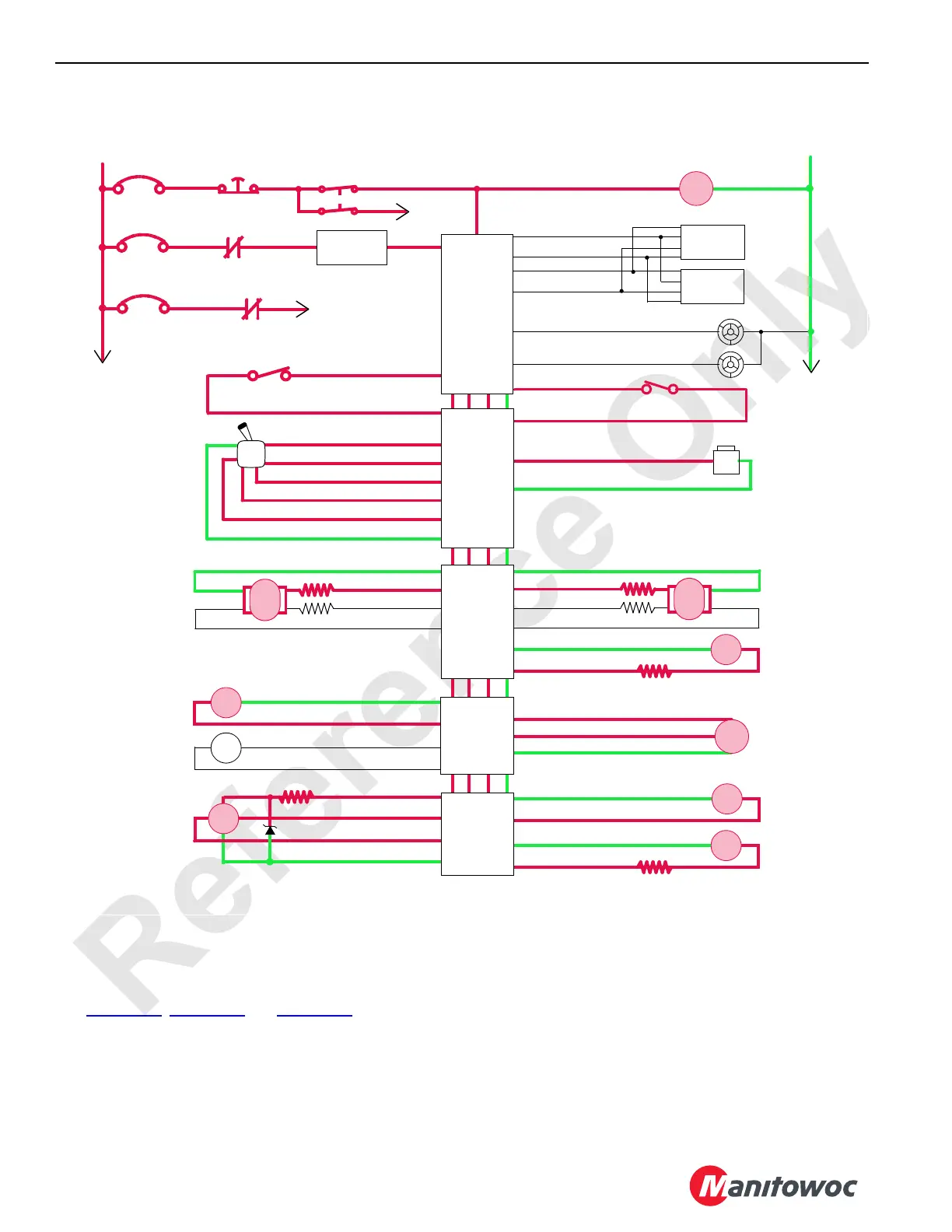

Drum 2 Electrical Schematic

LOAD/LUFFING DRUM 3

System Components

See Figure 1-26, Figure 1-27 and Figure 1-28.

The load/luffing drum 3 is located in the boom butt. The drum

can be configured either for luffing jib operation or as an

auxiliary drum. If drum 3 is rigged for luffing jib operation it

cannot be used as a load drum.

One hydraulic pump drives one motor gearbox on the left

side end of drum 3. The left travel pump is dedicated to

operate drum 3 though a diverging valve. The left track and

drum 3 cannot be operated at the same time. Hydraulic

connections between the pump and the motor form a closed-

loop system that is controlled with the control handle

movement and node controllers. The far load drum control

handle on the right side console operates drum 3 when

configured as a load drum. When configured as a luffing jib,

the control handle on the left side console operates drum 3.

DI P12-26

D0 52-32

Seat Switch

HS

16

Drum 1

Drum 2

Diverting

Gnd 43-D

DO 43-C

Drum2

Drum 1

Diverting

HS

21

Gnd 43-F

DO 43-E

Hyd

Psi

43-k Gnd

43-V 24 Volts

43-d AI

EDC

Gnd 34-G

Gnd 34-E

DO34-H

DO 34-F

Pump 4

Drum 1

Drum 2

EDC

34-K Gnd

34-L Gnd

34-S DO

34-M DO

Pump 6

Drum 2

Drum 1

+

–

PWR

CAB

System Fault Alarm

RCL Cab Fault Alarm

P11-07

P11-19

Display 1

Display 2

P11-01

P12-31

P12-32

P11-21

Start

WCP

CAN Power

Run 3

P12-24

Cab Power

Engine Stop

10 Amp

50 Amp

24 Volts

50 Amp

6C5A

6C5

CB7

6A

6C7

6C14

CB5

CB8

8C

8

HS

20

M/C

FIGURE 1-25

Drum 2

Park Brake

NODE 2

NODE 0

NODE 3

NODE 1

(Master)

NODE 4

NODE 5

DI P12-14

DO P52-07

DO P52-17

DI P51-08

DO P52-16

5 Volts P52-34

AI P51-04

Gnd P51-22

56-D DO

P52-25 Gnd

P52-02 DO

56-C Gnd

56-A Gnd

56-B DO

Drum 2

Control Handle

Handle

Rotation

Indicator

Drum 2

Pressure

Sender

RS Drum 2

Motor

Control

Drum 2

Brake

M/C

36-C Gnd

36-D DO

LS Drum 2

Motor

Control

SS

DO 56-g

EC1B 56-p

Drum 2 Motor

Speed Sensor

Gnd 56-j

EC1A 56-n

Raise

Lower

Raise

Lower

16-1020

Loading...

Loading...