HYDRAULIC SYSTEM 16000 SERVICE/MAINTENANCE MANUAL

2-22

Published 05-03-17, Control # 228-03

HYDRAULIC SYSTEM TEST, CALIBRATION,

AND ADJUSTMENT PROCEDURES

It is only necessary to perform the following procedures at

the specified intervals or when instructed to do so during

troubleshooting (see Section 10).

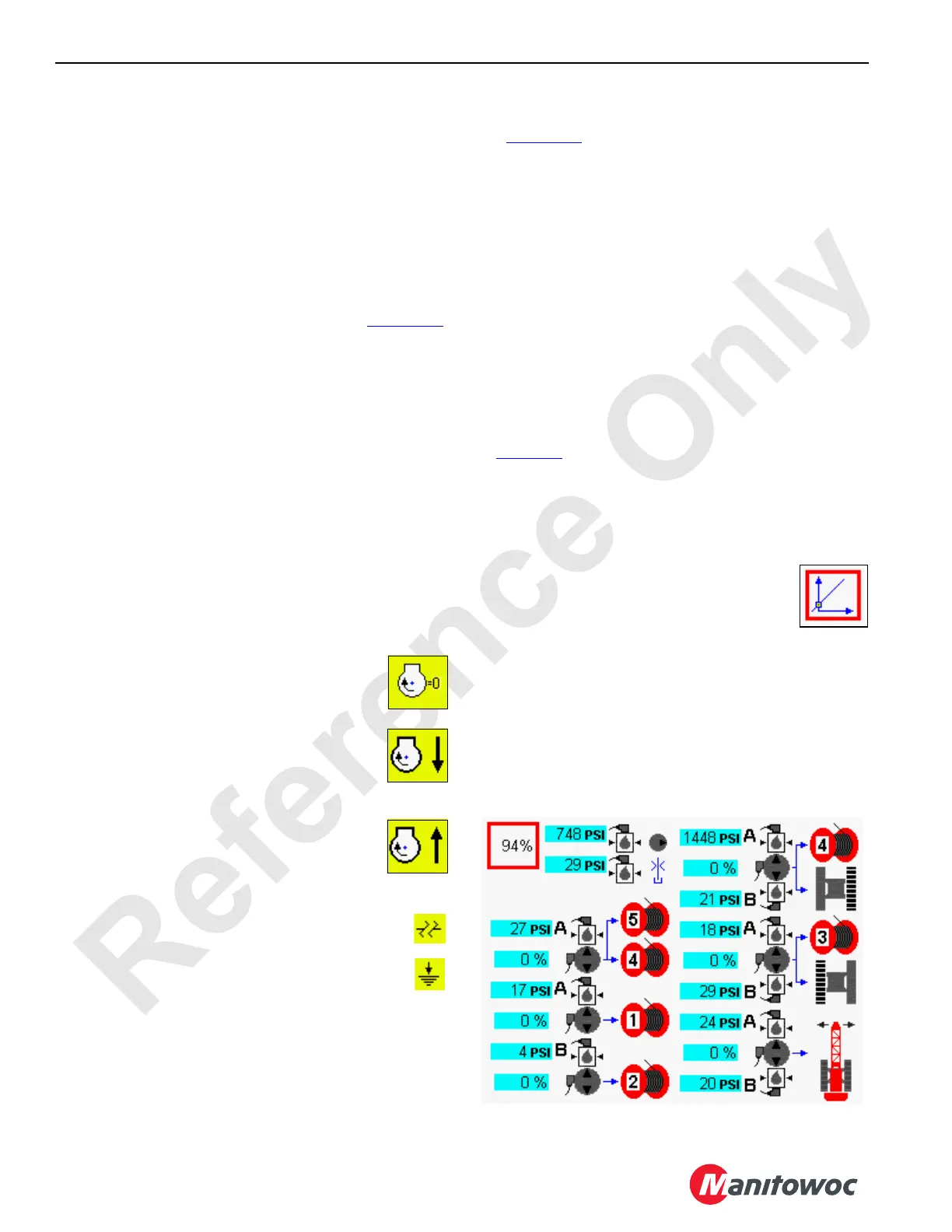

Pressure Test and Calibration Screen

NOTE: To understand the operation of the main display

and touch pad controls, read the instructions in

Section 3 or the 16000 Operator Manual.

The Pressure Test and Calibration Screen (see Figure 2-19

)

is used to initiate and monitor the four hydraulic test and

calibration procedures described in this section.

The screen shows the pump commands and pressure levels

for all primary crane functions. Use the data box in the upper

left corner of the screen to select and start a specific test or

calibration procedure.

The pressure Test and Calibration screen operates on two

levels.

Level 1—Test data box highlighted blue

Level 2—Test data box highlighted red. Use Select buttons

to choose the test or calibration procedure

All test and calibration procedures must be run at a particular

engine speed. If a test is started at the wrong speed, the

appropriate prompt shown below appears in the data box

and the procedure is aborted.

Engine Off

The yellow engine pressure 0 icon indicates that

the test must be run with the engine off.

Engine Low Idle

The yellow engine pressure down arrow icon

indicates that the test must be run with the engine

at low idle.

Engine High Idle

The yellow engine pressure up arrow icon

indicates that the test must be run with the engine

at high idle.

The yellow open-circuit icon indicates a circuit fault

that must be serviced immediately.

The yellow short-to-ground icon indicates a circuit

fault that must be serviced immediately.

Pressure Sender Test

See Figure 2-19 for the following procedure.

The pressure sender test calculates the zero-pressure

output level for each pressure sender. Pressure sender null

(0) must be with in 0.65 to 1.35 volts.

Perform this test when the following situations occur:

- A new pressure sender is installed

- A new controller node that monitors pressure

senders is installed

- A new master node or master node software is

installed

- Pressure readings are noticeably in error

Be aware that if there is any residual pressure in the system

during the calibration process, the display pressure reading

in the cab may not reflect actual system pressure. See Note

on page 2-23

.

Test pressure senders using the following procedure:

1. Stop the engine and turn the ignition switch to the run

position. Push the Enter button to go to the Pressure

Test and Calibration screen from the Menu screen.

2. Press the Enter button to go to level 2. Use

the Select buttons to show the PRESSURE

SENDER icon in the data box.

3. Press the Confirm button to start the test.

4. The test starts and the percent of completion is

displayed in the data box.

5. When the test is complete, the pressure sender icon

reappears in the data box.

The pressure senders must show a signal within a specified

range during this test. Any sender signal out of this range is

highlighted in yellow. Troubleshoot the failed senders to

determine the cause of the fault.

FIGURE 2-19

D16-26AA

Data

Box

Loading...

Loading...