HYDRAULIC SYSTEM 16000 SERVICE/MAINTENANCE MANUAL

2-6

Published 05-03-17, Control # 228-03

8. Analyze the hydraulic oil at regular intervals to

determine the condition of the oil and the extent of

system contamination.

By having the oil analyzed on a regular basis, the

established oil change interval can meet the operating

conditions.

NOTE: Contact the oil supplier for the availability and

process of oil analysis services.

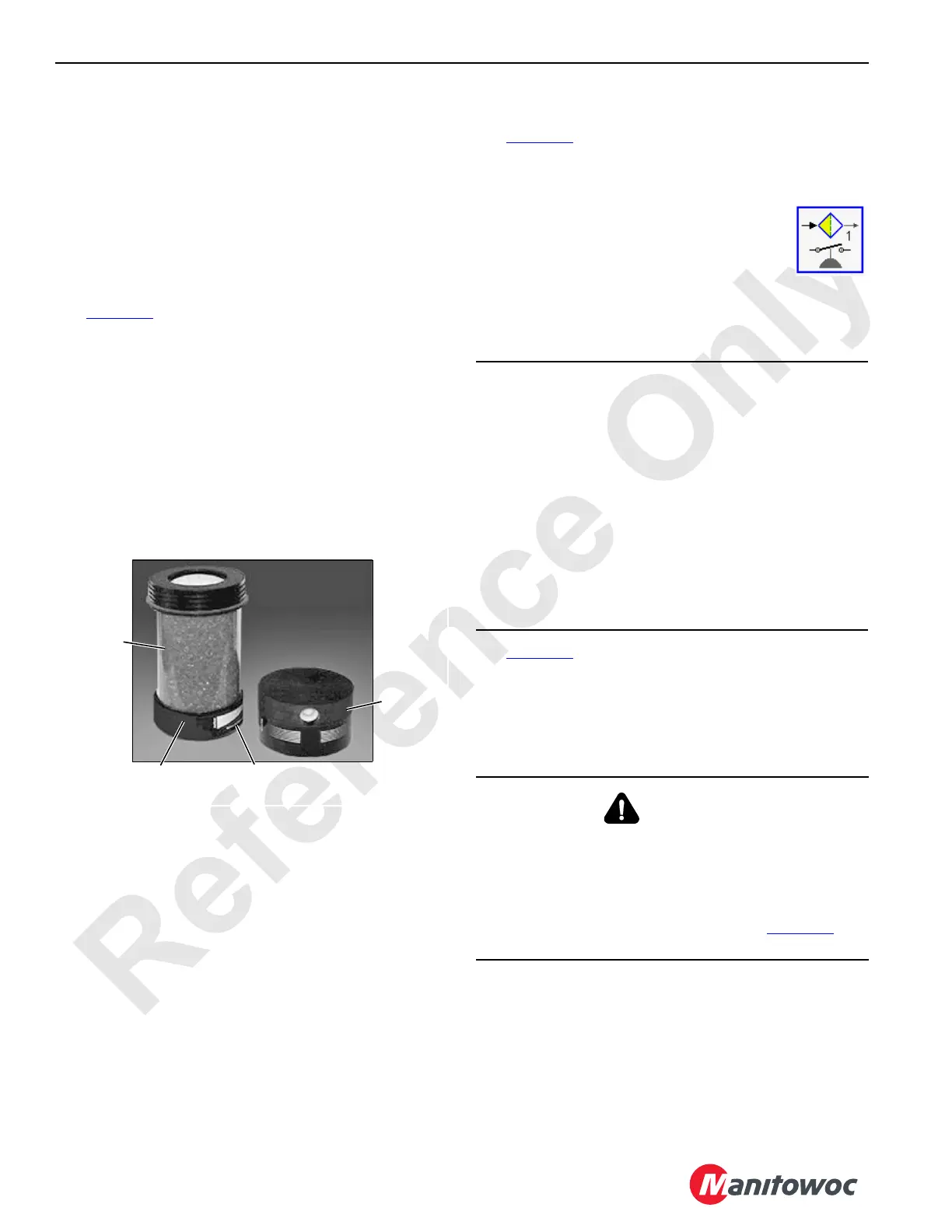

Replacing Desiccant Breather

See Figure 2-4 for the following procedure:

1. Remove the keyed cover above the hydraulic tank.

2. Unscrew the breather from the tank.

3. Unscrew the cap from the cartridge and discard the

cartridge.

4. Remove the protective caps from the top and bottom of

the new cartridge.

5. Attach the cap to the cartridge only to hand tightness.

6. Attach the breather to the hydraulic tank by hand

tightening.

Replacing Filters

See Figure 2-1 for the following procedure.

There are three 12-micron absolute filter elements that filter

all oil returning to the tank.

If a filter is too dirty, a fault alarm will come on

and a fault symbol will appear on the active

display. The hydraulic filter icon will appear on

the fault display.

NOTE: It is normal for the alert to come on at start-up when

the oil is cold. If the filters are not plugged, the alert

will turn off after the hydraulic oil warms up.

See Figure 2-1

for the following procedure.

Replace the return filter elements when the filter fault comes

on and at each oil change interval:

1. Stop the engine.

2. Remove the keyed cover above the hydraulic tank.

3. Clean the outside of the filter head around the cover.

4. Remove the fill cap. Do not damage the o-rings. The

fill cap has a hexagon stud for easy removal.

Desiccant

Beads

Service

Indicator

FIGURE 2-4

Reusable

Cap

Disposable

Cartridge

P2348b

CAUTION

Avoid Hydraulic System Damage!

The original equipment manufacturers’ filter elements,

available from Manitowoc Crane Care, must be used on

this crane. Substituting any other brand or type of filter

element is not allowed.

Filter elements made by other manufacturers may

collapse under pressure, which will allow unfiltered oil to

be drawn into the hydraulic system and can destroy

pumps, motors, and valves.

Manitowoc Crane Care will reject warranty claims for

damaged hydraulic components if the proper hydraulic

filter elements are not used.

WARNING

Burn Hazard!

Oil in the hydraulic tank may be under pressure and

extremely hot.

Hot oil can escape when either filter cover is removed.

Relieve pressure through the air valve (4a, Figure 2-1

) on

the tank before servicing.

Loading...

Loading...