Manitowoc Published 05-03-17, Control # 228-03 3-49

16000 SERVICE/MAINTENANCE MANUAL ELECTRIC SYSTEM

Camera Screen (Optional)

The camera screen sets the desired camera operation. The

camera option includes up to three different cameras to

monitor drum spooling and the area behind the crane.

Use the select buttons to select the camera screen from the

menu screen. Press the enter button to access the screen.

Use the select buttons to select the desired camera view.

When done, press the exit button until the menu screen

appears.

Pressure Test and Calibration Screen

The pressure test and calibration screen initiates and

monitors the hydraulic test and calibration procedures. For

instructions to run these tests, refer to Section 2.

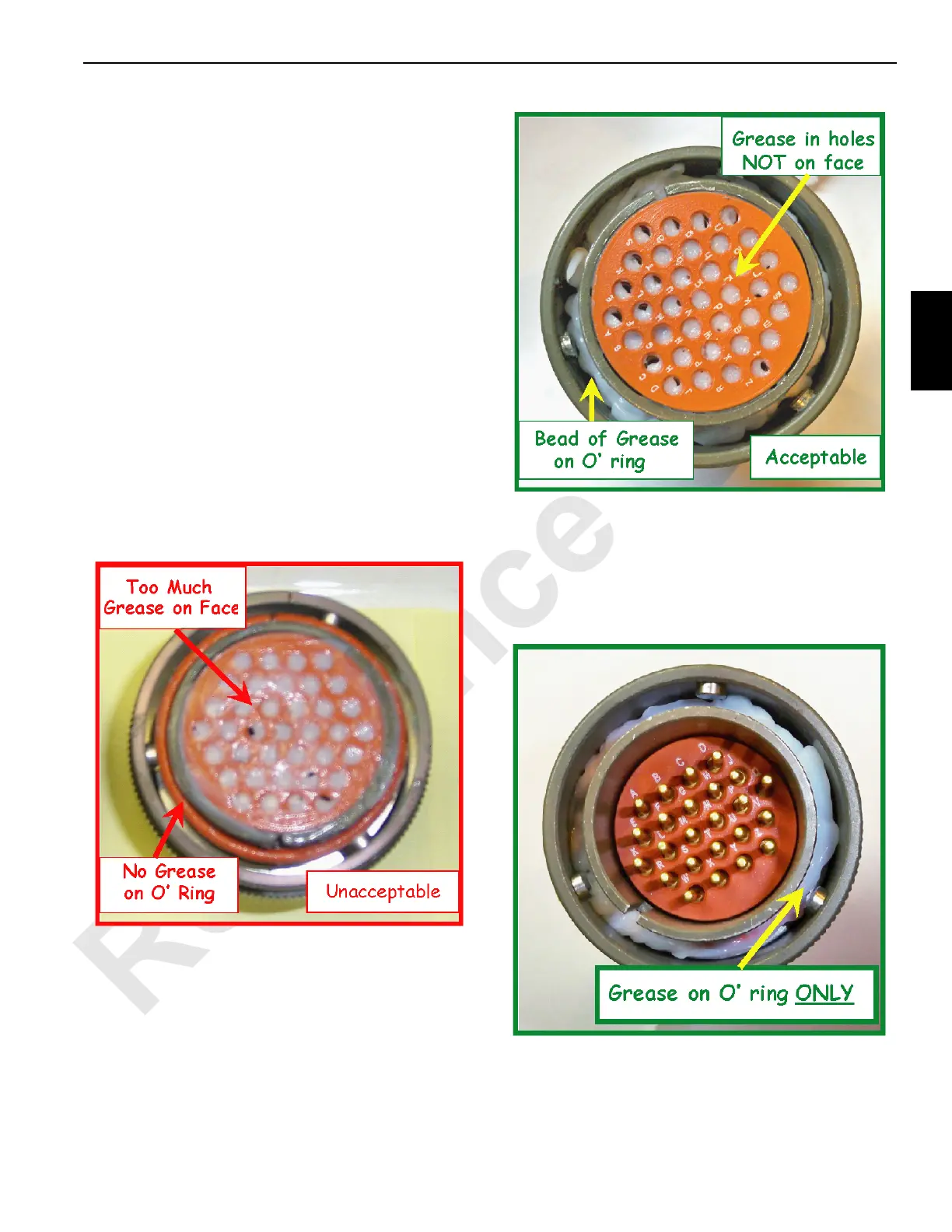

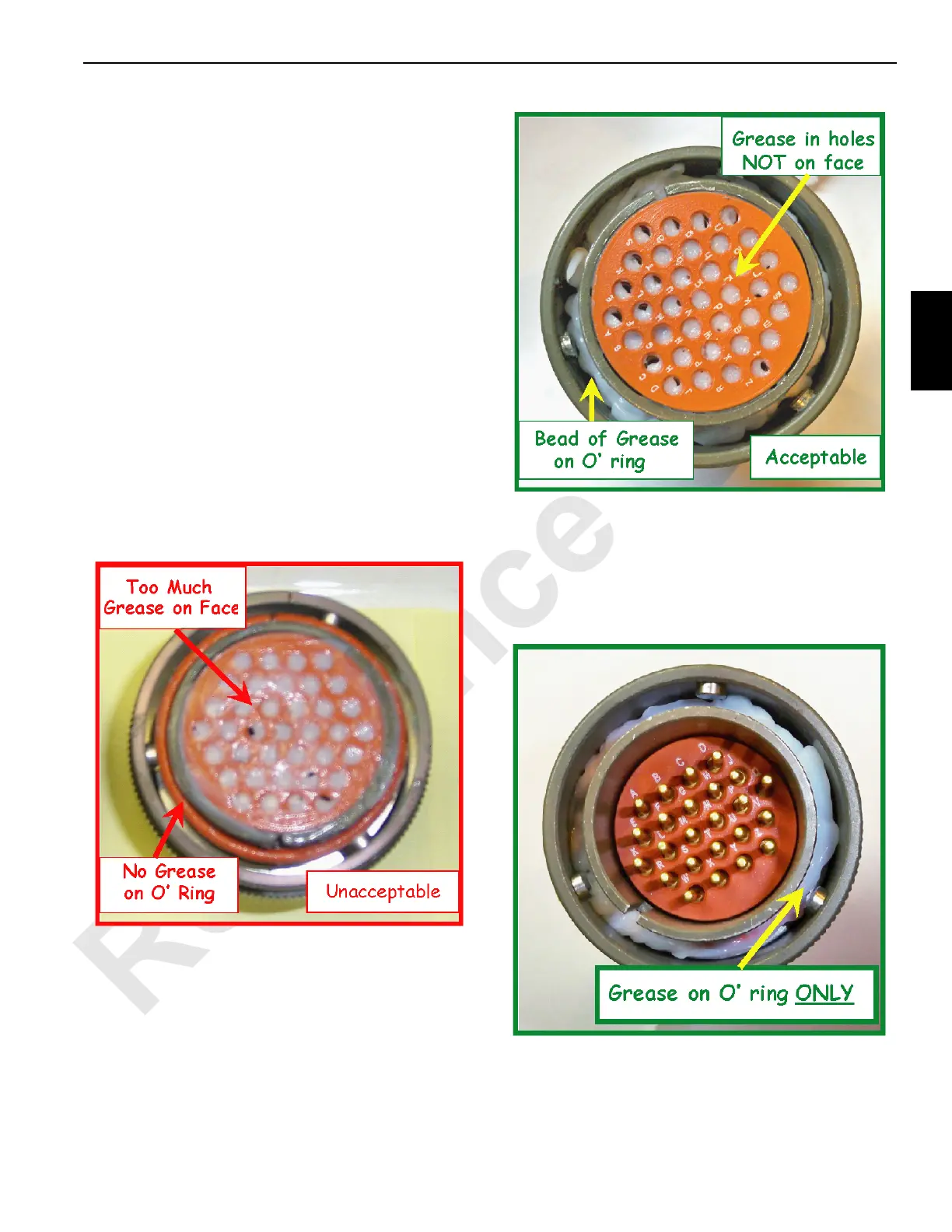

DIELECTRIC GREASE

The following figures show the proper application of

dielectric grease on all J-tech type connectors.

Dielectric grease is needed when assembling the J-tech type

connectors. Apply a bead of grease on the o-ring and face of

the socket connector. Apply a bead of grease on the o-ring of

the pin connector. Do not apply grease to the face of the pin

connector.

Use the following sizes when applying the bead of grease:

• On a 3-pin connector, apply a 1,5 mm (1/16 in.) bead.

• On a 24-pin connector, apply a 3 mm (1/8 in.) bead.

• On a 37-pin connector, apply a 5 mm (3/16 in.) bead.

To apply the grease to the connector face, place a small

amount of grease on your finger. Wipe your finger across the

face, applying grease inside the socket holes with a layer

less than 0,025 mm (0.001 in.) on the connector face. This

keeps water out of the connectors and keeps the pins from

fretting.

Loading...

Loading...