Manitowoc Published 05-03-17, Control # 228-03 2-23

16000 SERVICE/MAINTENANCE MANUAL HYDRAULIC SYSTEM

NOTE: The cause of a failed pressure sender test or faulty

display pressure reading may not be the pressure

sender. The cause of the fault could be trapped air

or hydraulic pressure in the system during the

pressure sender test.

Before replacing a pressure sender, do the

following:

• Perform the pressure sender test.

• Attach an accurate hydraulic pressure gauge

to the quick-coupler at the suspect pressure

transducer (see topic in this section).

• If the pressure appears on the gauge, bleed

the corresponding system so the gauge reads

zero pressure.

• Repeat the pressure sender test and check the

pressure on the display with the engine

running at idle — the display reading and the

gauge reading should be the same.

• Before replacing a pressure sender, check the

signal voltage at the sender. It should be 1.00

volt against ground at 0 psi.

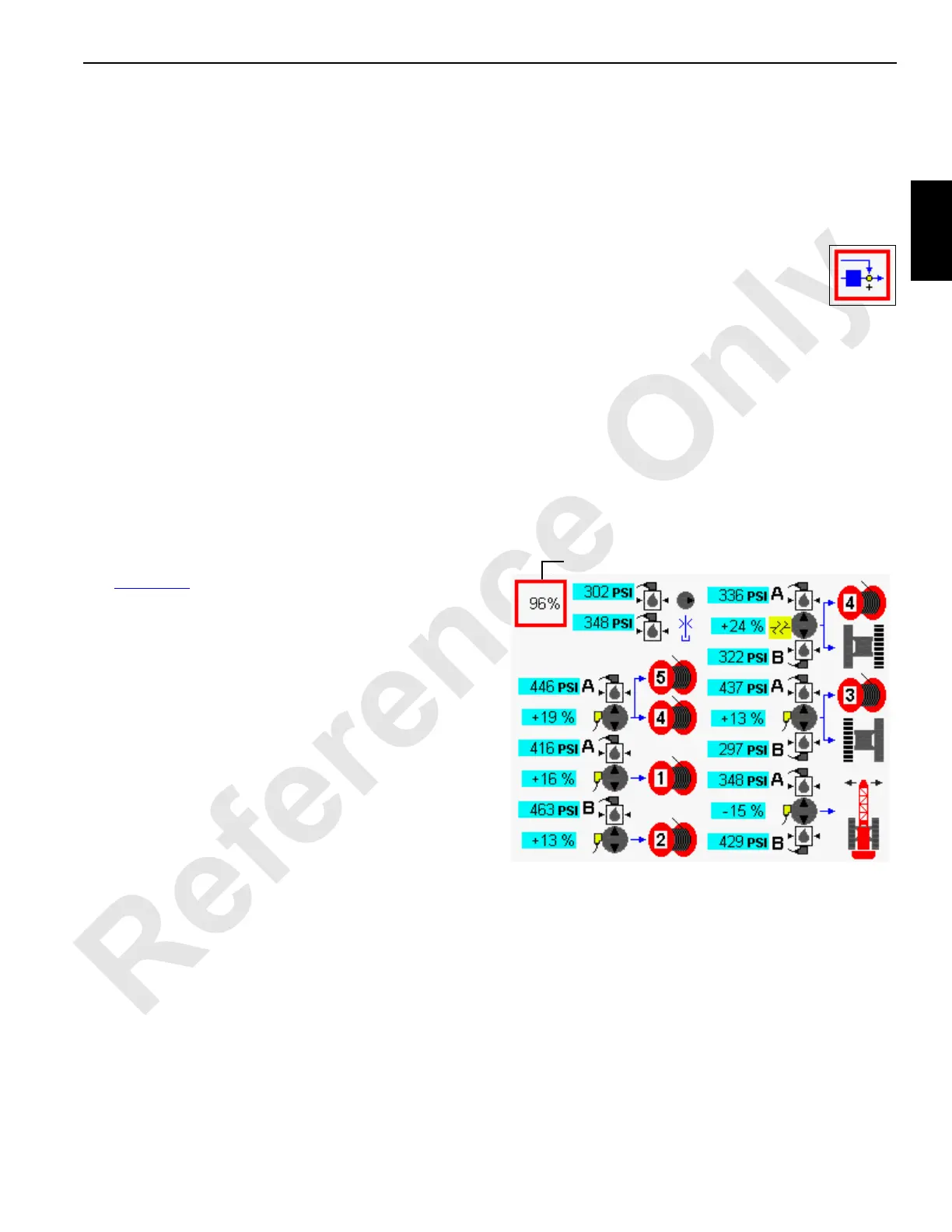

Control Calibration

See Figure 2-20 for the following procedure.

Control calibration calculates the pump threshold command

level for all drum and swing functions. The allowable range is

5 to 25% pump command signal for the hoist pumps and 2.5

to 20% in each direction for the swing pump(s).

Perform this calibration when the following situations occur:

- A new pump or motor is installed in a drum or swing

function

- A new master node or master node software is

installed

- Operation indicates the threshold is in error,

including excessive handle motion or time required

to initiate motion or inability to start motion smoothly.

Calibrate controls using the following procedure:

1. Apply all park brakes with the switches on the control

console.

2. Start and run the engine at high idle.

3. Press the Enter button to go to the Pressure Test and

Calibration screen from the Menu screen.

4. Press the Enter button to go to level 2. Use

the Select buttons to show the CONTROL

CALIBRATION icon in the data box.

5. Press the Confirm button to start the test.

6. The Calibration starts and the percent of completion is

displayed in the data box.

7. When the calibration is complete, the control calibration

icon reappears in the data box.

Pump threshold command levels must be within a

specified range during this test. Any pump requiring a

threshold command level outside this range is

highlighted in yellow. Troubleshoot the failed circuit to

determine the cause of the fault.

FIGURE 2-20

D16-27B

Data Box

Loading...

Loading...