Manitowoc Published 05-03-17, Control # 228-03 1-53

16000 SERVICE/MAINTENANCE MANUAL INTRODUCTION

Mast Raising from Transport Position

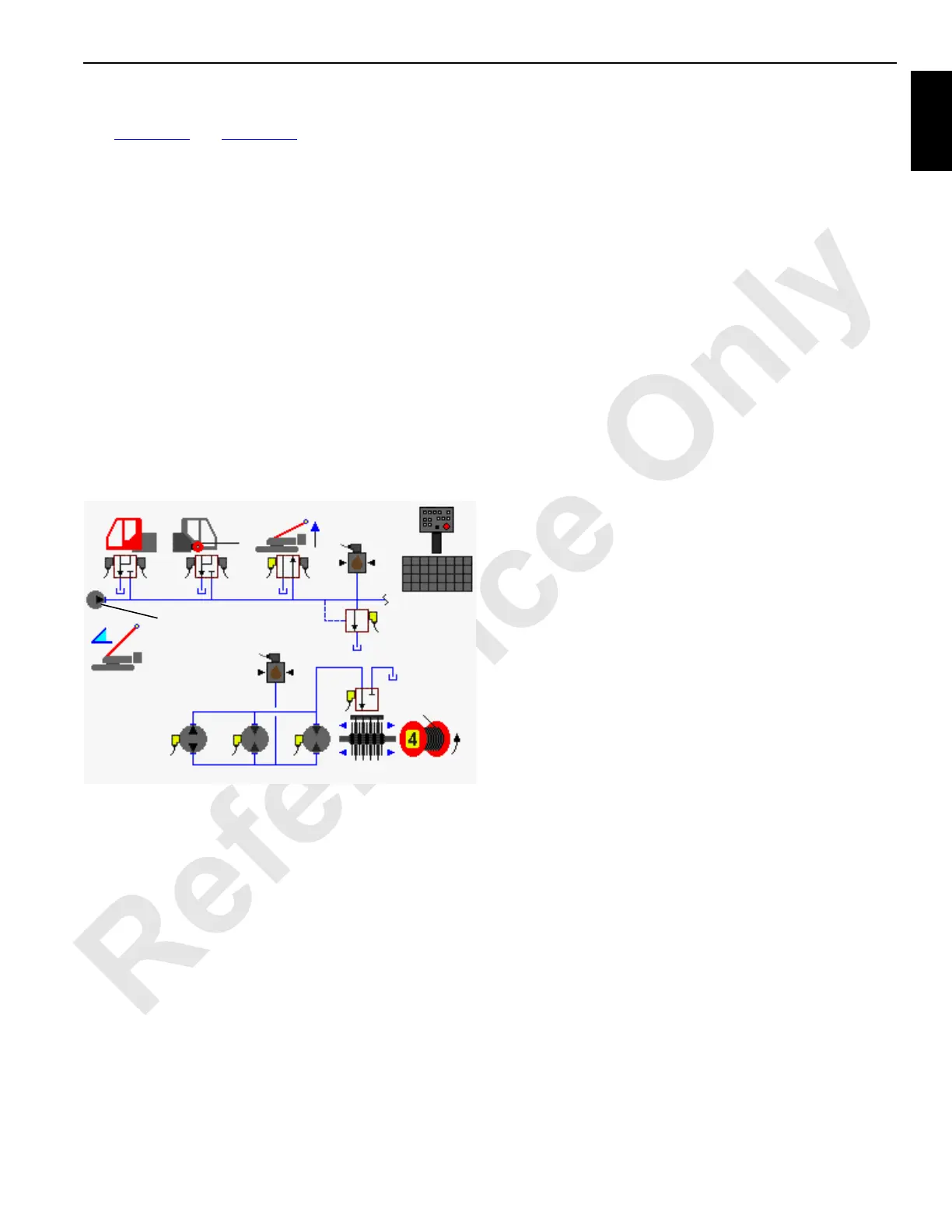

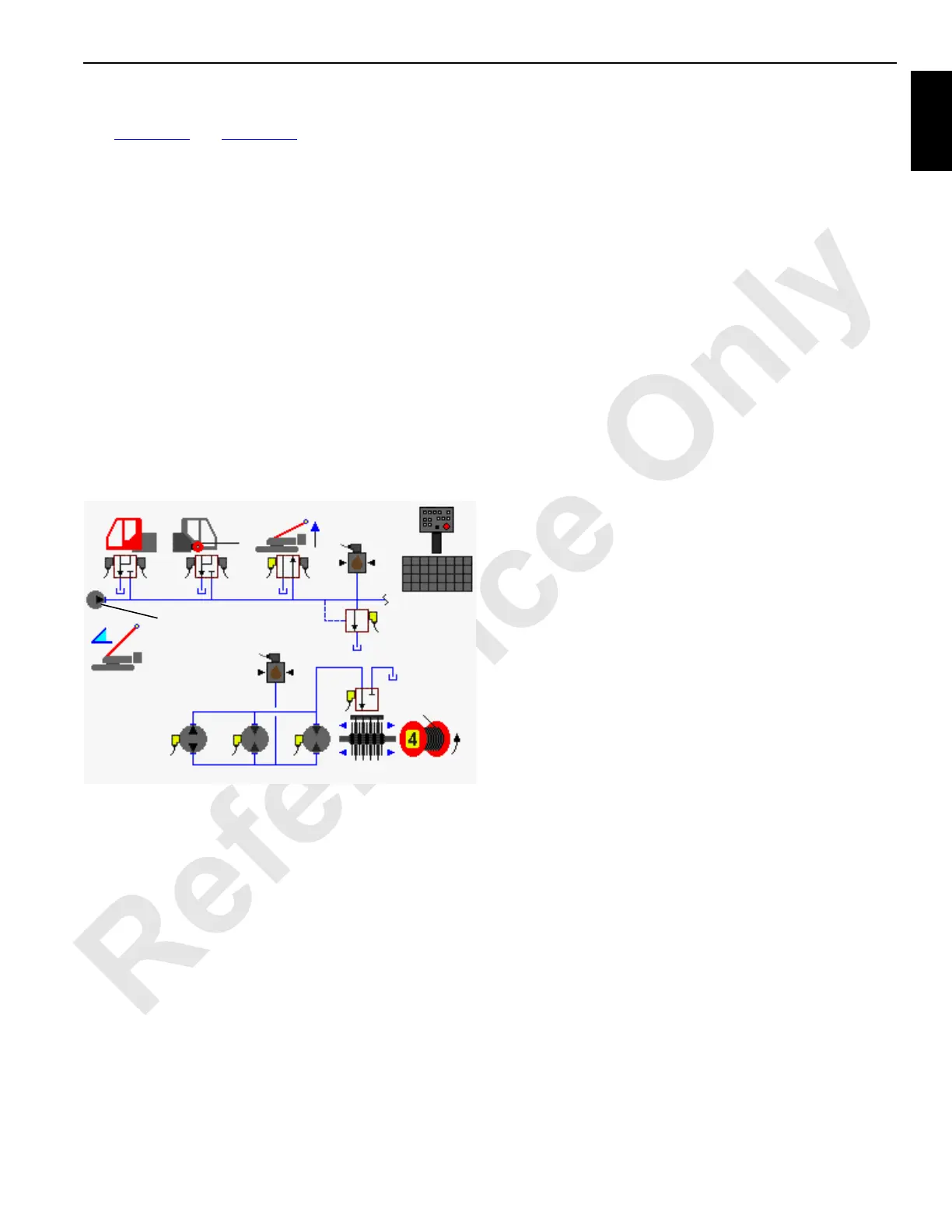

See Figure 1-44 and Figure 1-45.

Use the RCL Screen to select the Liftcrane Mast Handling

Capacity Chart. The mast controls will not operate and the

mast operating limits remain off until the Liftcrane Mast

Handling Capacities Chart is selected.

Use the mast switch on the hand-held wireless remote to

raise the mast assist arms until the cylinders stall and stop.

When the boom/mast hoist control handle is moved forward

for lowering, an input voltage of 2.4 volts or less is sent to

the Node-1 controller. The Node-3 controller sends a

variable 0 to 24 volt output that is divided by a resistor and

applied to the boom/mast hoist pump EDC in the down

direction.

The Node-4 controller sends a 24 volt output to enable the

mast cylinders extend solenoid HS-50 and shifts the valve to

the extend position. The Node-3 controller sends a variable

0 to 24 volt output to enable the accessory system

proportional relief solenoid HS-68.

The Node-1 controller compares the drum holding pressure

to the value in the pressure memory. When the system

pressure is high enough, the Node-4 controller sends a 24

volt output to drum brake solenoid HS-10. The drum brake

valve shifts to block the drain port and opens the port to the

low-pressure side of the pump to release the brake.

The boom/mast hoist pump EDC strokes the pump in the

down direction. The Node-4 controller sends a 24 volt output

to enable the mast raising cylinders solenoid HS-50 in the

extend (mast raising) direction. The valve shifts to block the

tank port and open the port to the accessory system

pressure. The Node-3 controller sends a variable 0 to 24 volt

output to enable the accessory system proportional relief

solenoid HS-68.

The mast assist arm cylinders extend automatically as the

mast raises from the transport position. The boom/mast hoist

drum pays out the wire rope between the drum and the mast

sheaves. A speed sensor at motor rotor monitors the drum

rotational speed.

Fluid pressure from the accessory valve enters the free-flow

check valve sections on side A of the load equalizing valve.

From the equalizing valve, fluid enters the counterbalance

valves and piston end of the mast cylinders, extending the

cylinder rods to raise the mast. The Node-4 controller

monitors the accessory system pressure to control the mast

cylinder raising the speed rate.

Fluid flow from the rod end of the mast raising cylinders is

blocked by the free-flow check valve sections on side B of

the counterbalance valves and flows through the valve flow

restrain sections preset for a relief pressure of 240 bar

(3,481 psi). The counterbalance valves operate with a 5:1

pilot ratio of the relief valve pressure, permitting the valve to

open when the pressure in rod end of the cylinders is

approximately 48 bar (696 psi). Hydraulic fluid from side B

sections of both the counterbalance valves combines, and

the free-flow check valve section on side B of load equalizing

valve blocks the flow.

The fluid then passes through the valve flow restrain section

that is preset at 276 bar (4,003 psi). The load equalizing

valve operates with a 1.5:1 pilot ratio of the relief valve

pressure, permitting the valve to open when the hydraulic

pressure on side A of the load-equalizing valve is

approximately 185 bar (2,683 psi). The restraining section on

side B of the load equalizing valve opens, controlling the flow

of fluid out of the cylinders to ensure the cylinder operation is

balanced.

When the mast cylinders are extending, the Node-4

controller monitors the drum speed sensor. The Node-1

controller maintains a speed that is proportional to the

accessory system hydraulic pressure applied to the mast

raising cylinders. The mast assist arms will stop rising

automatically when the mast assist cylinders are fully

extended (approximately 115°).

The Node-3 controller monitors the mast angle sensor when

the mast is moving. The diagnostic screen monitors the mast

operating angle. When the mast is raised to the operating

range of 115° to 145°, the Node-3 controller sends a zero

output voltage to the pump EDC. When the control handle

center switch opens, the Node-4 controller sends a zero volt

output to disable the brake solenoid HS-10 to apply the

brake before pump de-strokes.

The Node-3 controller sends a variable 24 volt output signal

to the pump EDC to de-stroke the pump. The Node-4

controller sends a zero output voltage to shift the spool of

mast raising cylinder solenoid HS-50 to the center position.

The Node-3 controller sends a zero volt output to disable the

accessory system proportional relief solenoid HS-68.

FIGURE 1-44

Pressure

Sender

Accessory

Pump

Mast Raising

Cylinders

HS-68

HS-51

HS-50

Pressure

Sender

Drum 4

Pump

Drum 4

Motors

HS-10

16-1037

Loading...

Loading...