Chapter 8: Maintenance

103

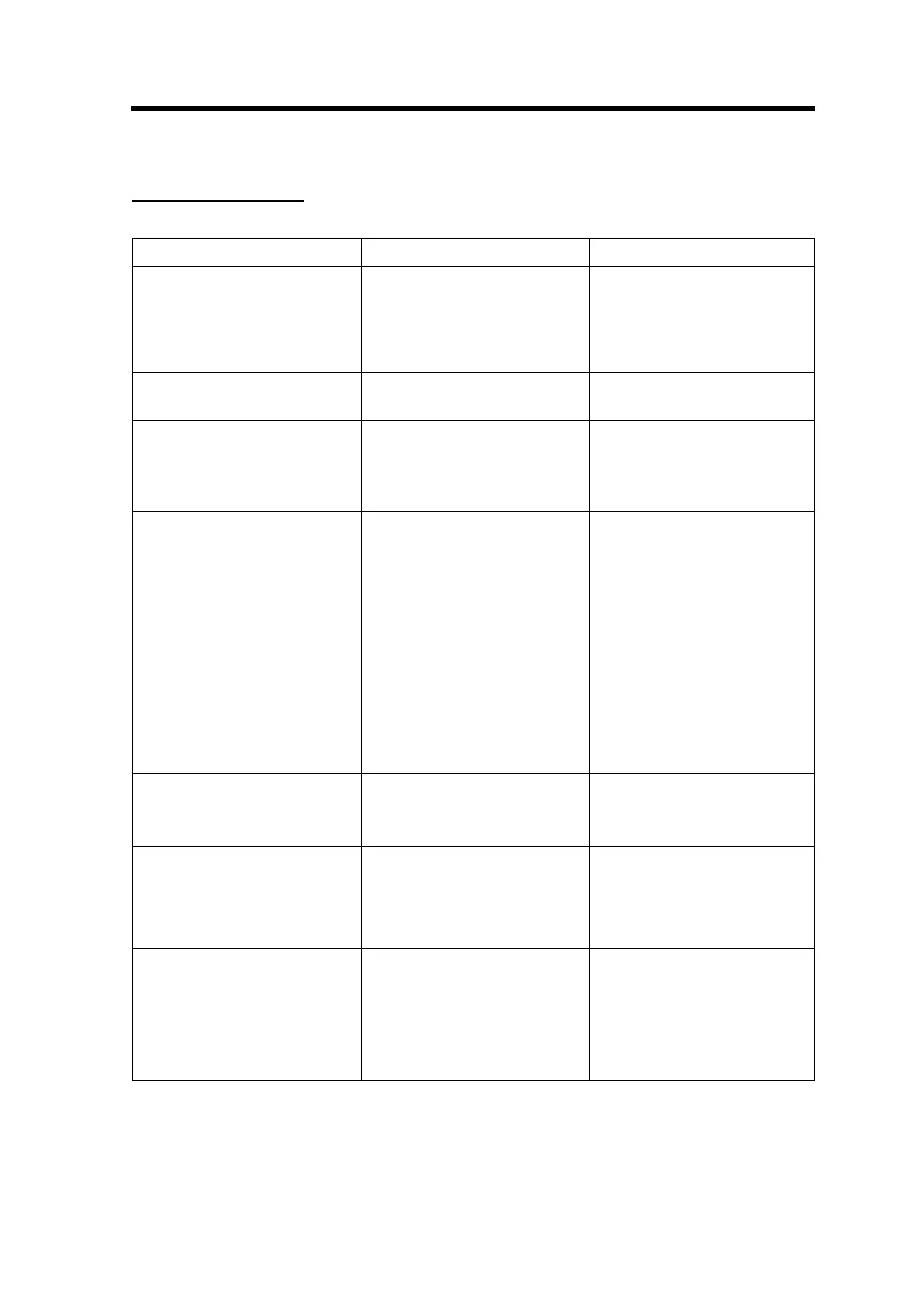

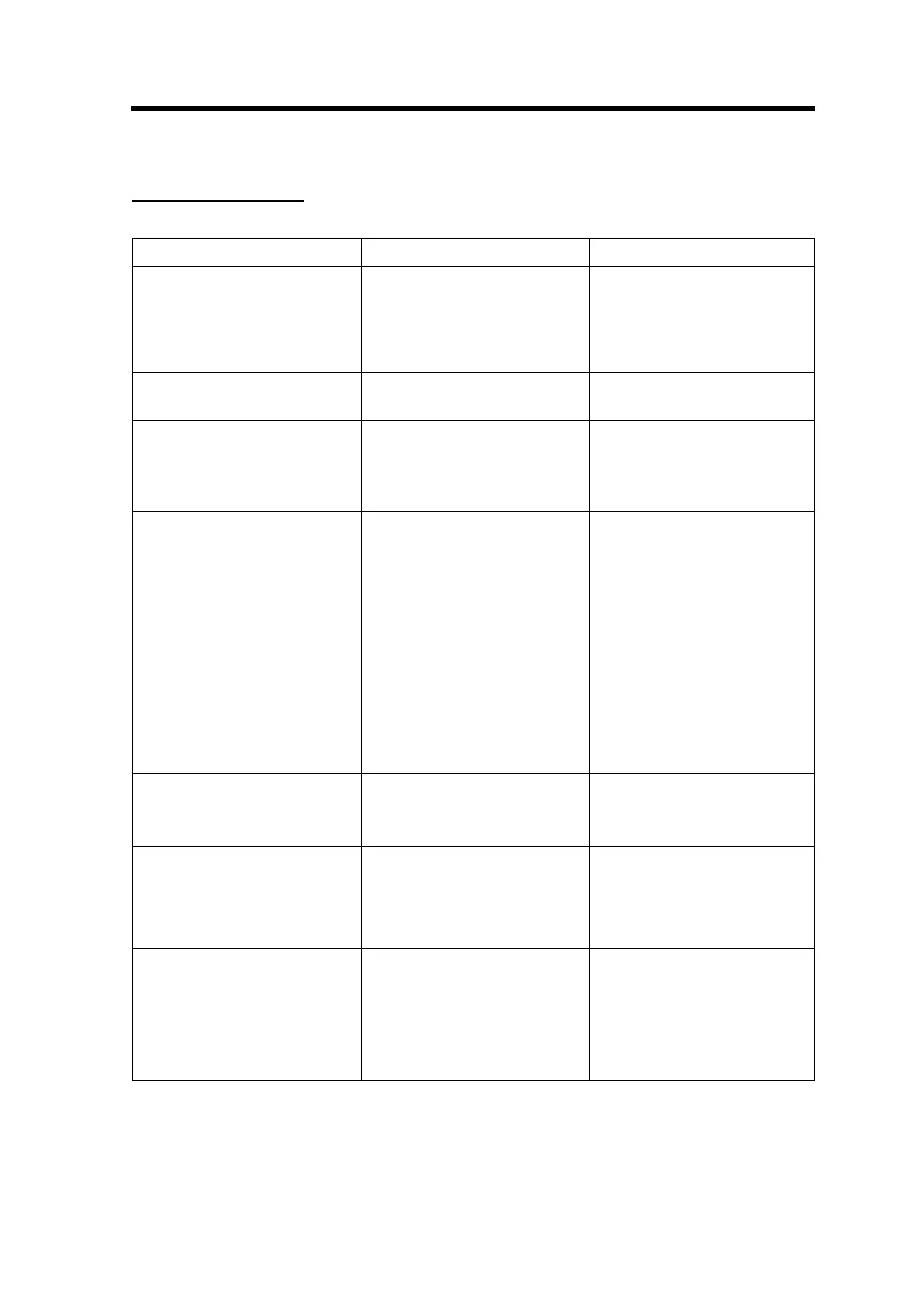

Troubleshooting

Symptoms Possible Cause Remedy

No output or overrange at zero

(after warm-up)

Improper cable

Valve override function applied

(Mass flow controller)

Electronics malfunctioning

Check cable for type

Disconnect / disable valve

override

Return for service

Unit indicates a negative flow

Unit installed in gas stream

backwards

Reinstall unit in proper flow

direction

Controller does not track set

point.

Improper zero adjustment

Improper grounding(s)

Zero meter output

Check all ground connections.

Check signals, if possible

directly at the unit’s connector

Controller does not function

Electronics malfunctioning

Valve sticking, clogged,

contaminated, corroded.

Shutoff valve upstream or

downstream closed

No inlet pressure

Return for service

Check compatibility of the

process gas with materials

wetted (corrosion is typically

also visible inside the process

fittings)

return for service

Open shutoff valve first, then

apply again setpoint to the

unit.

Regulate inlet pressure

Oscillation Supply pressure unstable, e.g.

defective pressure regulator.

Supply pressure too high

Check manufacturers’

specifications

Reduce upstream pressure

Excessive closed conductance Inadequate valve preload

Valve seat elastomer damaged

return for service

Check compatibility of process

gas with seat material

return for service to replace or

change valve seat elastomer

Unit does not achieve full flow

Upstream pressure too low

Excessive valve preload

Valve seat disc damaged, e.g.

swollen

Increase upstream pressure

return for service

Check compatibility of process

gas with seat material

return for service to replace or

change valve seat elastomer

Table 7 Troubleshooting

Loading...

Loading...