NORDAC FLEX (SK 200E ... SK 235E) – Users Manual for Frequency Inverters

142 BU 0200 en-3118

Pos: 31 2 /Anlei tung en/El ektr onik/FU und Star ter/5 . Par ameter/ Par ameter aufli stung (P000 .. .)/P1 00-P1 99/Par amet er P107 – Einfal lzei t Br e mse @ 0\mod_1327575190328_388.docx @ 7642 @ @ 1

P107

Brake reaction time

(Brake reaction time)

P

0 ... 2.50 s

{ 0.00 }

Electromagnetic brakes have a physically-

dependent delayed reaction time when actuated. This

can cause a dropping of the load for lifting applications, as the brake only takes over the load after

a delay.

The reaction time must be taken into consideration by setting parameter P107.

Within the adjustable application time, the FI supplies the set absolute minimum frequency (P505)

and so prevents movement against the brake and load drop when stopping.

If a time > 0 is set in P107 or P114, at the moment the FI is switched on, the level of the excitation

current (field current) is checked. If no magnetising current is present,

magnetising mode and the motor brake is not released.

In order to achieve a shut-down and an error message (E016) in this case, P539 must be set to 2

or 3.

See also the parameter >Release time< P114

Pos: 31 3 /Anlei tung en/El ektr onik/FU und St art er/5 . Par amet er/ Par amet erau fli st ung (P 000 .. .)/P 100- P199 /Par amet er P107 – Ei nf allz eit Bre mse _Inf o An st euer ung durc h FU [S K 2xxE , SK 2xx E-FD S] @ 5\mod_1396521387504_388.docx @ 124000 @ @ 1

Brake control

The relevant connection on the frequency inverter must be used to actuate the

electromechanical brake (particularly with lifting mechanisms), if present

chapter 2.4.2.4 "Electromechanical brake"). The minimum absolute frequency (P505) should

never be less than 2.0 Hz.

Pos: 31 4 /Anlei tung en/El ektr onik/FU und Star ter/5 . Par ameter/ Par ameter aufli stung (P000 .. .)/P1 00-P1 99/Par amet er P107 – Einfallzeit Bremse_Info Drehmomentbegrenzung [SK 2xxE, SK 180E, SK 2xxE-FDS] @ 19 \mod_1505892985870_388.docx @ 2365489 @ @ 1

Information

Torque limitation during active setpoint delay

(P107 / P114)

During an active setpoint delay, the torque is limited to a maximum of 160% of the rated

torque. This prevents the occurrence of excessive currents in the inverter or breakdown of the

motor if

• For application of the brake, the brake reaction time (P107) is set too long.

• For release of the brake, the value for the absolute minimum frequency (P505) is set too

high.

Pos: 31 5 /Anlei tung en/El ektr onik/FU und Star ter/5 . Par amet er/ Par amet erau fli st ung (P 000 .. .)/P 100- P199 /Par amet er P107 – Ei nf allz eit Bre mse _Beis pi el @ 4\mod_1396519433556_388.docx @ 123851 @ @ 1

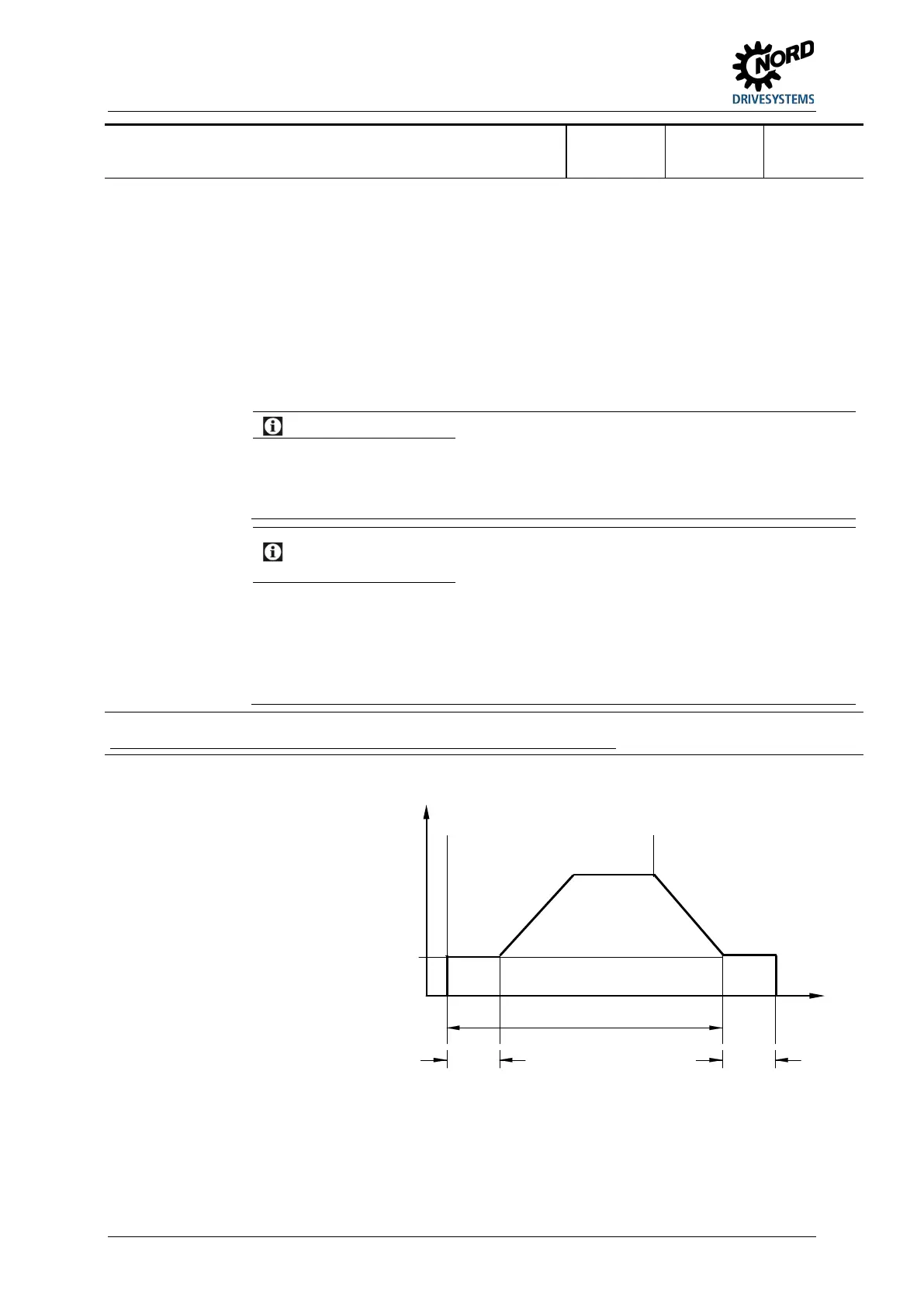

Recommendation for applications:

Lifting equipment with brake, without speed feedback Lifting equipment with brake

P114 = 0.02...0.4 s *

P107 = 0.02...0.4 s *

P201…P208 = Motor data

P434 = 1 (ext. brake)

P505 = 2...4 Hz

for safe start-up

P112 = 401 (off)

P536 = 2.1 (off)

P537 = 150 %

P539 = 2/3 (I

SD

monitoring)

to prevent load drops

P214 = 50...100 % (precontrol)

* Settings (P107/114) depending on

brake type and motor size. At low power

levels (< 1.5

kW) lower values apply for

higher power ratings (> 4.0

larger values.

P114

or

P107, when P114 = 0

Pos: 31 6 /Allgemein/Allgemeingültige Module/---------Seiten umbruc h komp akt --------- @ 13\mod_1476369695906_0.docx @ 2265495 @ @ 1

Loading...

Loading...