Routing and splicing the fiber cable 7-39

AccessNode Series 800A Outside Plant Cabinet Installation 323-3001-210 Issue 1.0

Procedure 7-4 (continued)

Routing fiber to the ABM when no FPP is installed

Step Action

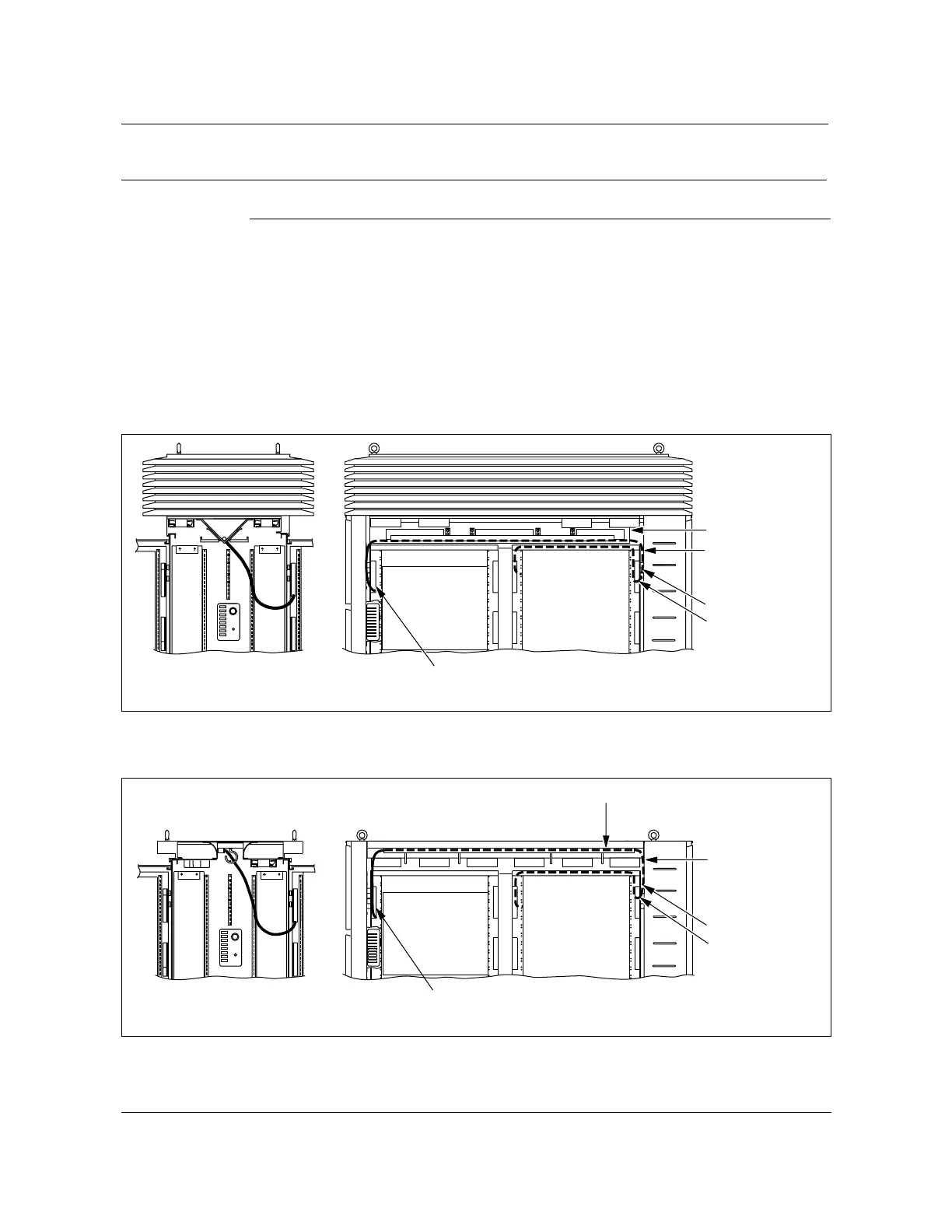

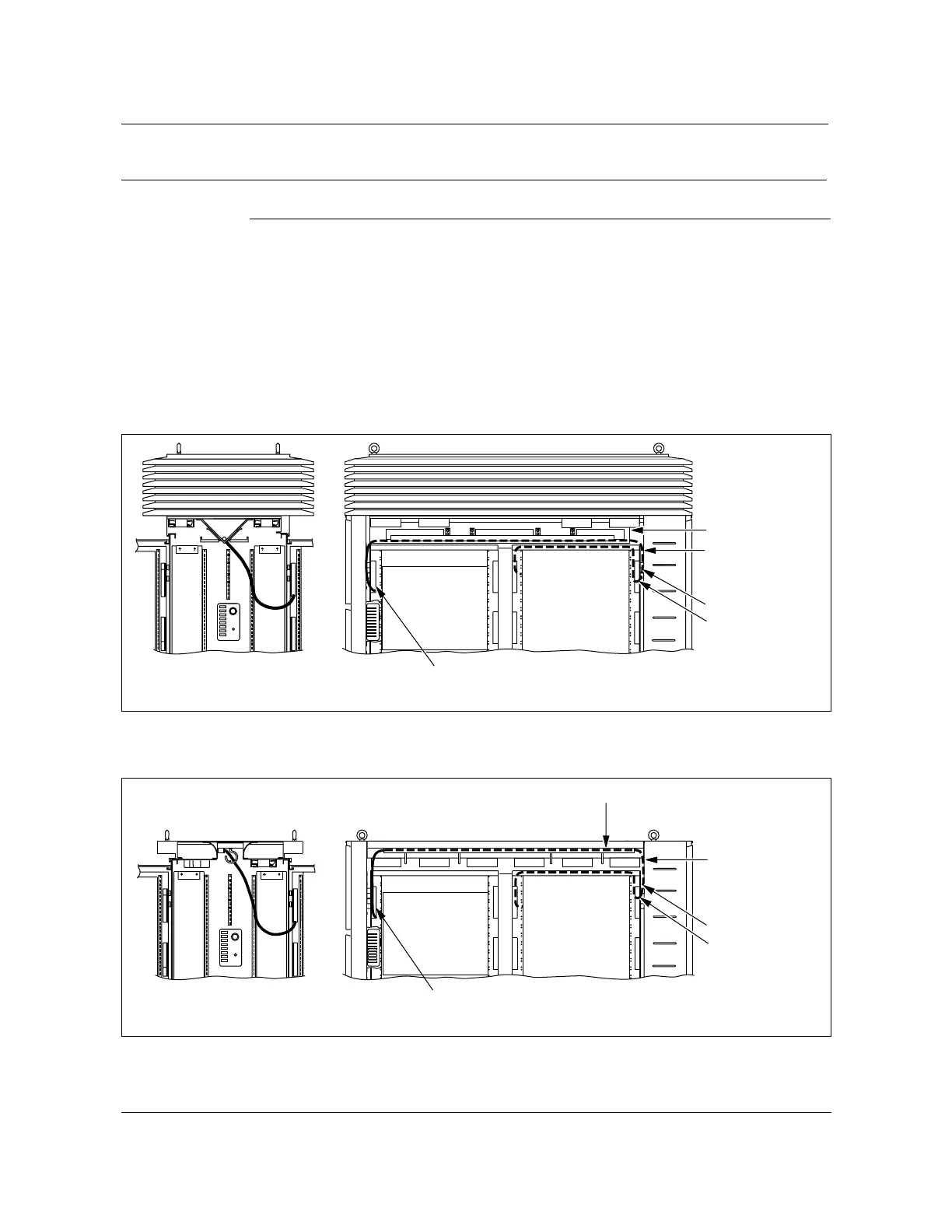

6 Route tubing across the ceiling of the cabinet as per the type of roof assembly

on the rear side of the air baffle (see Figure 7-20 or Figure 7-21).

Note 1:

For the heat exchanger roof, route the fiber inside the V-baffle

enclosure (see Figure 7-20).

Note 2:

The air induction roof has a cable hooks for all cable routing (see

Figure 7-21).

7 Tie wrap the fiber cable to the cabinet ceiling as per the type of roof assembly.

Figure 7-20

Tie wrap the fiber cable to the ceiling of the heat exchanger roof assembly

FW-15144

Figure 7-21

Tie wrap the fiber cable to the ceiling of the air induction roof assembly

FW-15145

—continued—

Rear view

Maintain at least

minimum bend

radius

3.0 in. (76 mm)

Swing frame cutout

Left inside view

V- trough

TerminationFrontRear AC

FW-15144

Service loop

ABM

Fiber patch cords

Rear view

Maintain at least

minimum bend

radius

of 3.0 in. (76 mm)

Swing frame cutout

Left inside view

TerminationFrontRear AC

FW-15145

Plastic cable duct

Service loop

Fiber patch cords

ABM

Loading...

Loading...