45530603TH Rev.2

2-4

Oki Data CONFIDENTIAL

2. DESCRIPTION OF OPERATION

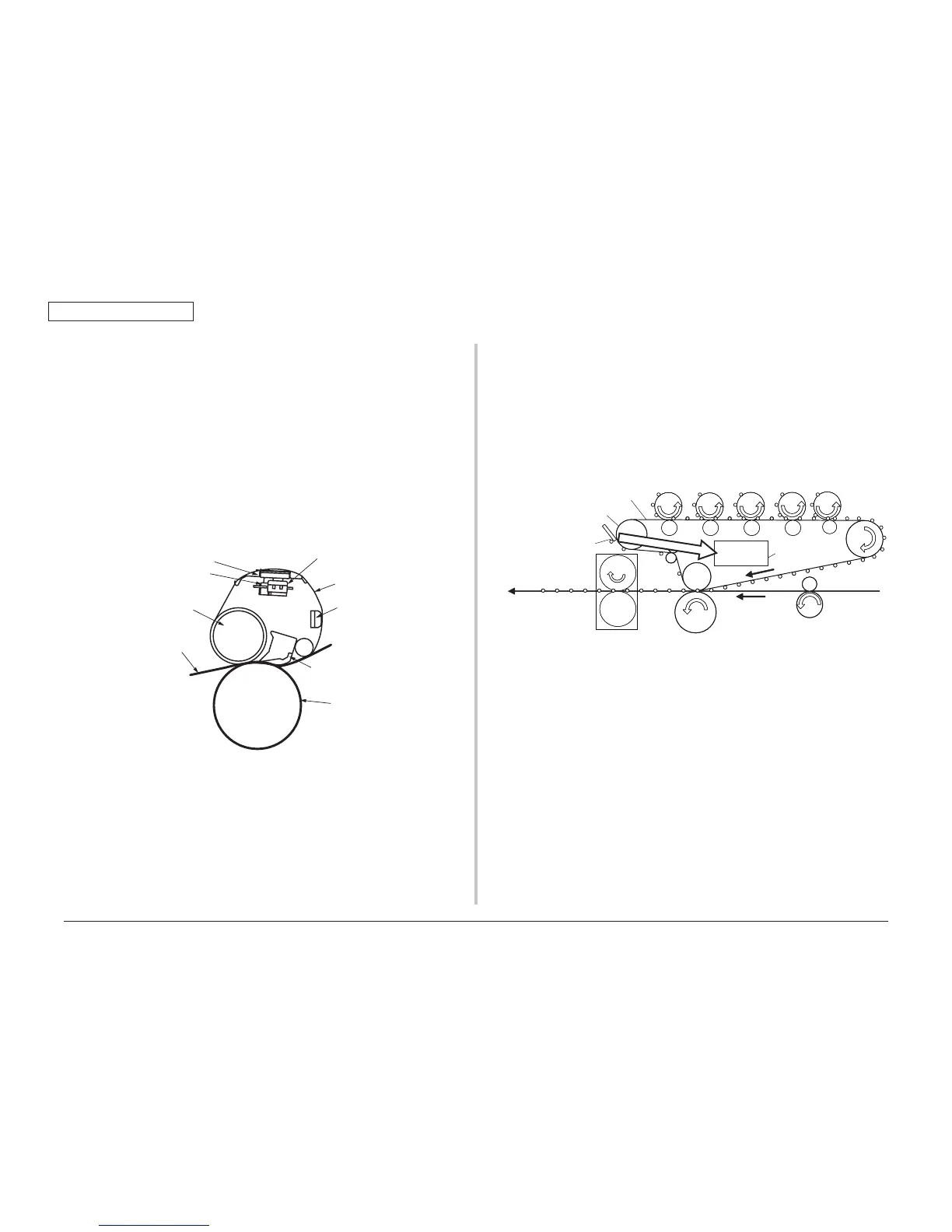

(6) Fusing

The toner image transferred on the paper is fused to the paper by heat and

pressure when the paper passes through between the portion of the fuser belt

(mainly comprised with the fuser roller, the pat and the fuser belt) and the pressure

roller in the fuser unit.

The fuser belt unit is heated by internal heater Assy. with specified wattage (e.g.

1200W in 230V environment). The fusing temperature is determined by the value

of the temperature that is the measurement of the thermistor. The thermistor is

arranged as it is contacted with the inside of the fuser belt.

There is also a thermostat for safety purposes. When the heater temperature rises

above a specific temperature, the thermostat opens and shuts down the power

supplied to the heater. The pressure roller is pressed against the fuser belt by press

springs those arranged both sides of the pressure roller.

Heater Assy

Pad

Fuser belt

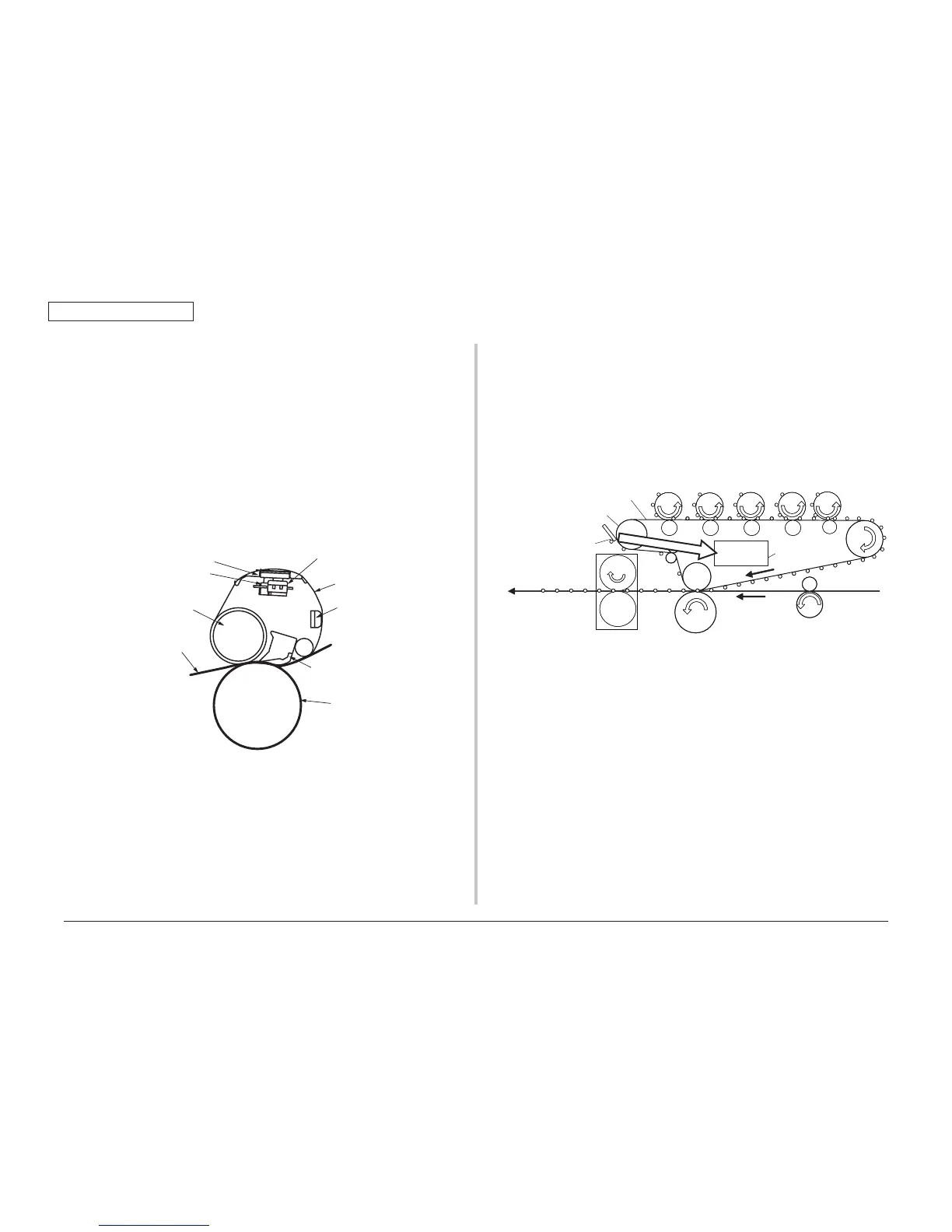

(7) Drum cleaning

Unfixed toner remaining on the OPC drum is removed by the drum cleaning blade

and collected into the waste toner area of the toner cartridge.

(8) Belt cleaning

To ne r r em ai ni ng on th e i nt er m ed ia te tr an sfe r be lt is sc ra pe d o ff by th e b el t cl ea nin g

blade and collected into the waste toner box of the transfer belt unit.

Drum

Belt cleaning blade

(9) Intermediate transfer roller cleaning

Toner remaining on the intermediate transfer roller is return to transfer belt by

electric field cleaning, and clean by belt cleaning structure.

Loading...

Loading...