45530603TH Rev.2

2-5

Oki Data CONFIDENTIAL

2. DESCRIPTION OF OPERATIO N

2.2 Printing process

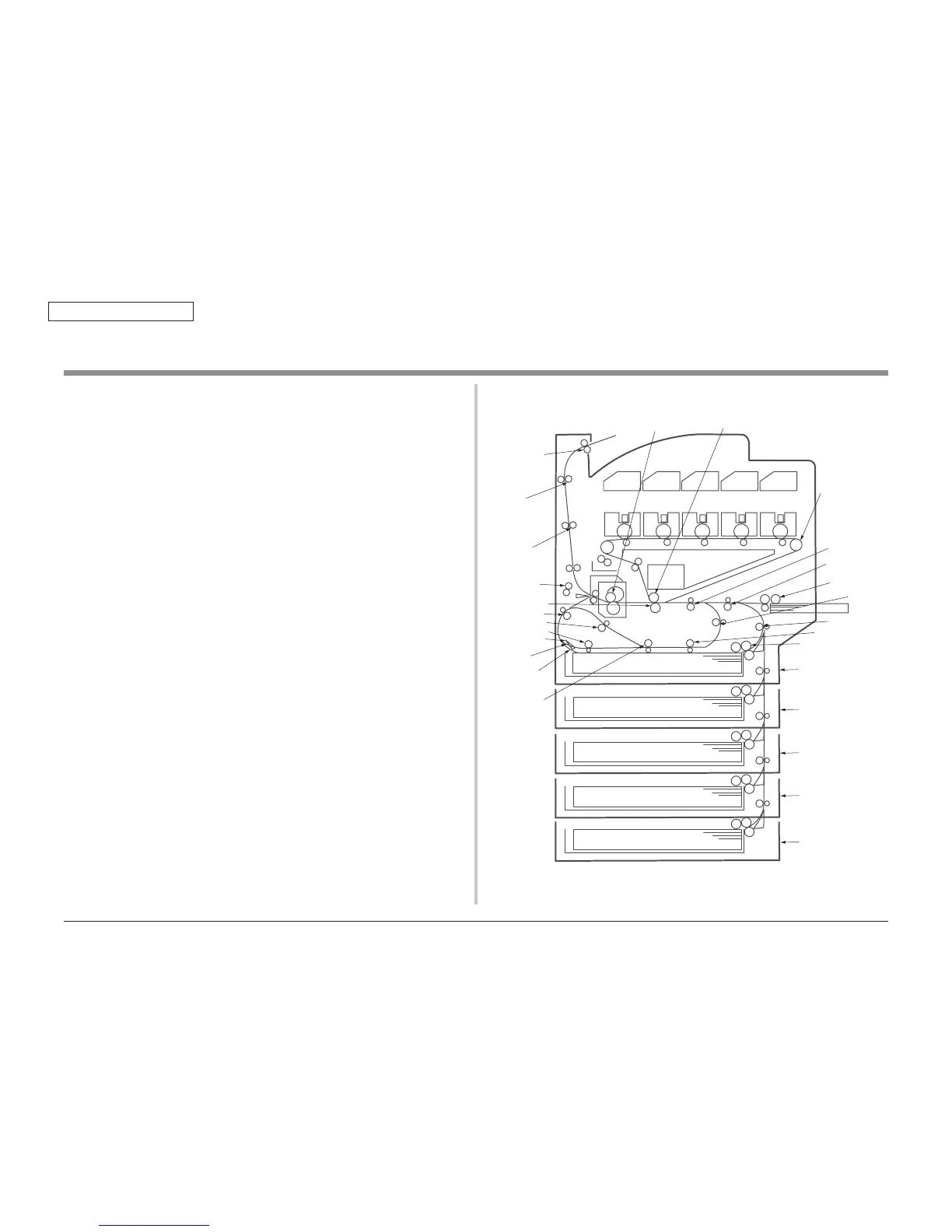

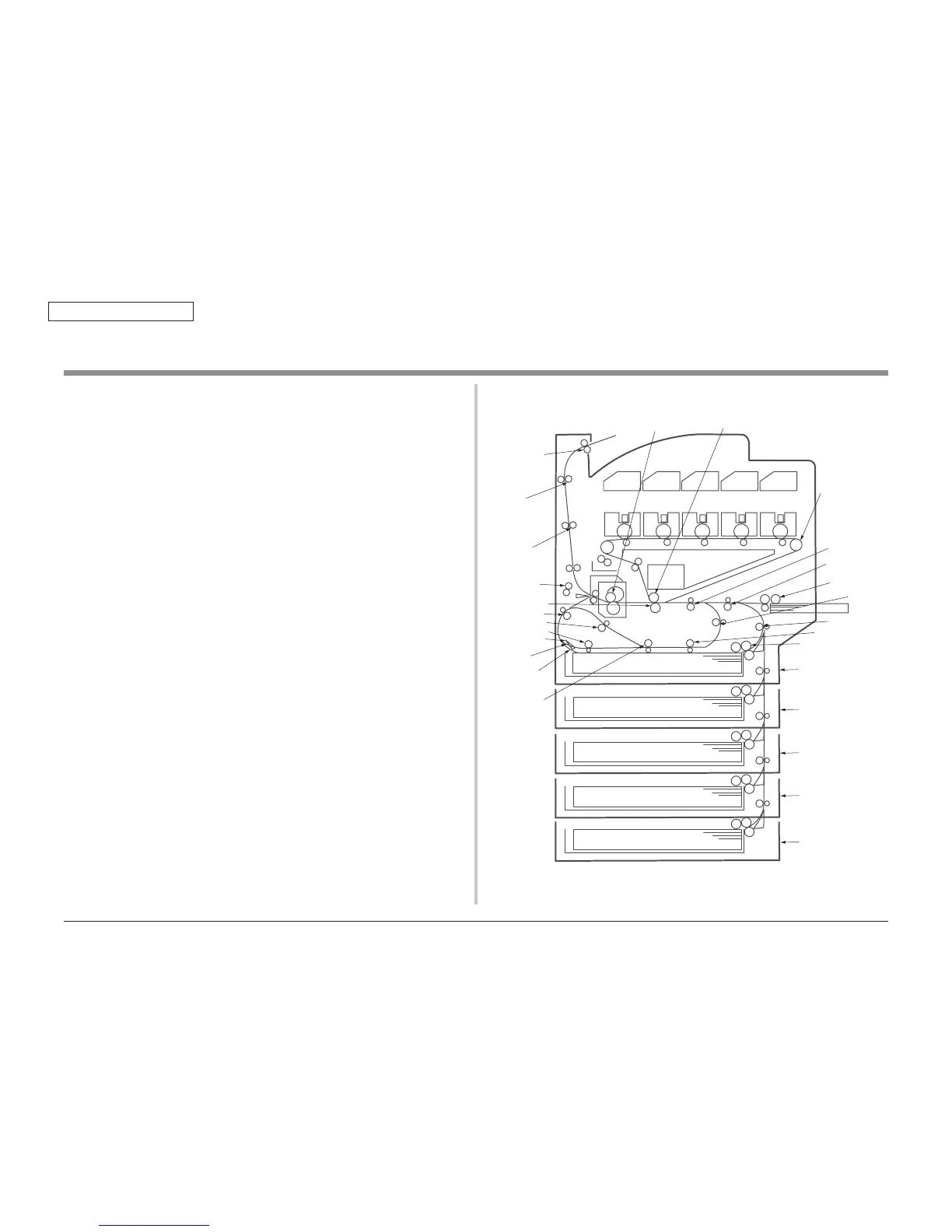

The paper fed from Tray 1 or Tray 2, 3, 4 or 5 is fed by the paper feed roller, registration 1

roller, registration 2 roller and timing roller. When the paper is fed from the MPT, it is fed by

the MPT paper feed roller and the registration 2 roller.

Next, the paper fed to the TR2 roller is nipped by the TR2 BU roller arranged in the

intermediate transfer belt and TR2 roller.

Then, an unfused toner image which has been formed on the belt of the intermediate transfer

belt is transferred on the transported paper.

The unfused toner image is formed onto the belt sequentially through the each color

electrophotographic process as SP-Color(White or Clear toner (only 5-color model)), Y, M, C

and K.

Thereafter, the toner image is fused to the paper under heat and pressure as the paper

passed through the fuser unit.

After the toner image has been fused to the paper, the paper is ejected to a face-up stacker

or to a face-down stacker (which is depended on the preselected outputting method).

The above refers to the one-sided (Simplex) printing operation of the printer. Below, its

operation in bose-sided (Duplex) printing be explained.

When Duplex printing is set, the paper that has passed through the fuser unit following first

one-sided (to back-side) printing is transported into the Duplex unit by the separation of

the Duplex separator. After the paper is entered the paper reverse transportation path, the

paper is transported from there to the inside of the Duplex unit by the reversal motion of the

DUP reverse roller. Then, the paper which passed through the Duplex unit by the DUP 1, 2,

3, and DUP REG roller that is fed from the paper feed route of the Duplex. After the paper

is eventually transoprted to the same route that comes from the trays. From here on, for to

other one-side (front-side) printing, the same operation as that of one-sided print of paper fed

from the tray takes place.

When printing with 2 Pass, the paper is transported into the Duplex unit as in the Duplex

printing after the base printing. After the paper is entered the paper reverse transportation

path, the paper is transported to the 2 Pass transport path by the 2 Pass separator without

the reversal motion. After the paper is eventually transoprted to the route as same as in the

Duplex printing inside the Duplex unit. From here on, for to other one-side (front-side) printing,

the same operation as that of one-sided print of paper fed from the tray takes place.

Registration 2 roller

MPT paper feed rolle

Loading...

Loading...