Manual Version e1-4.3.0.ae-R3. Page

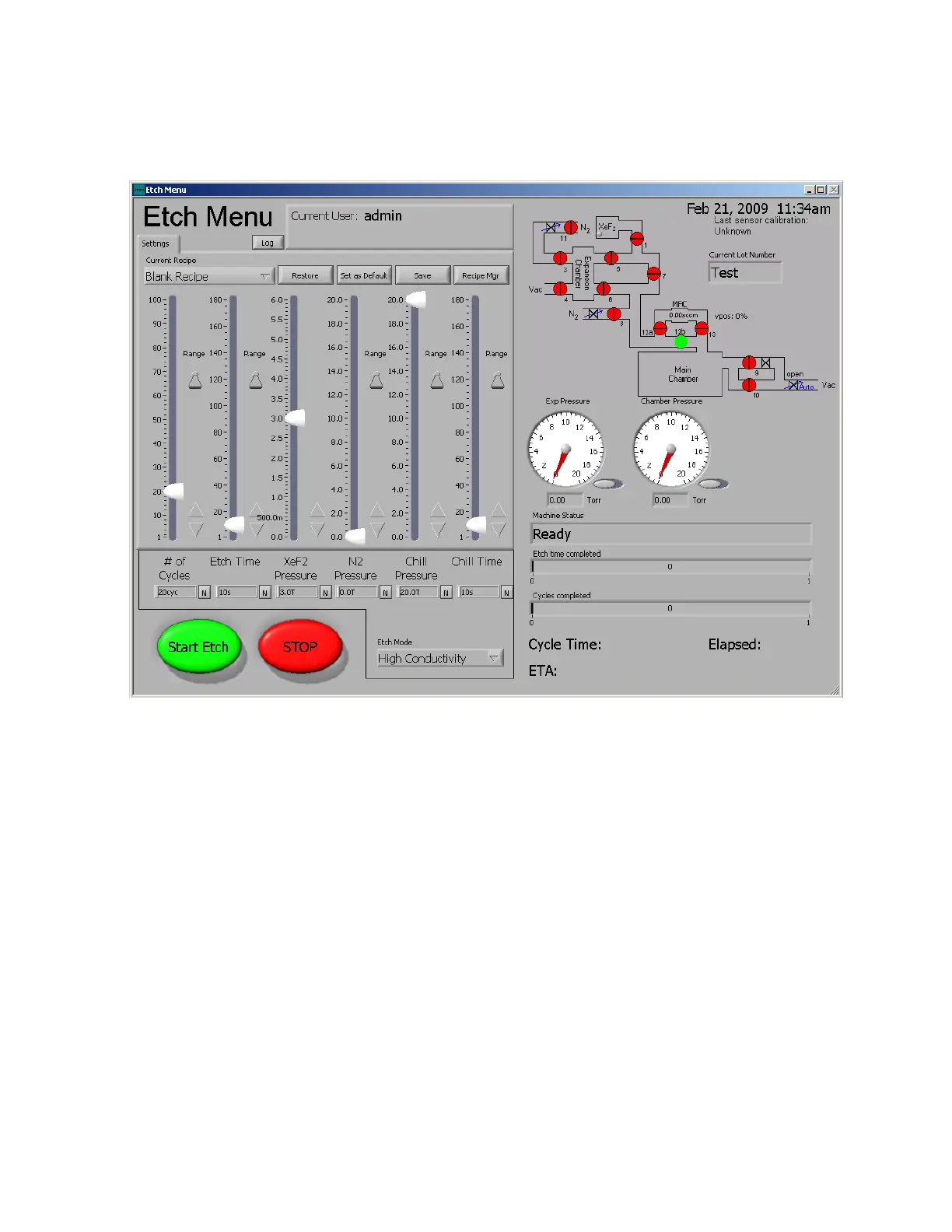

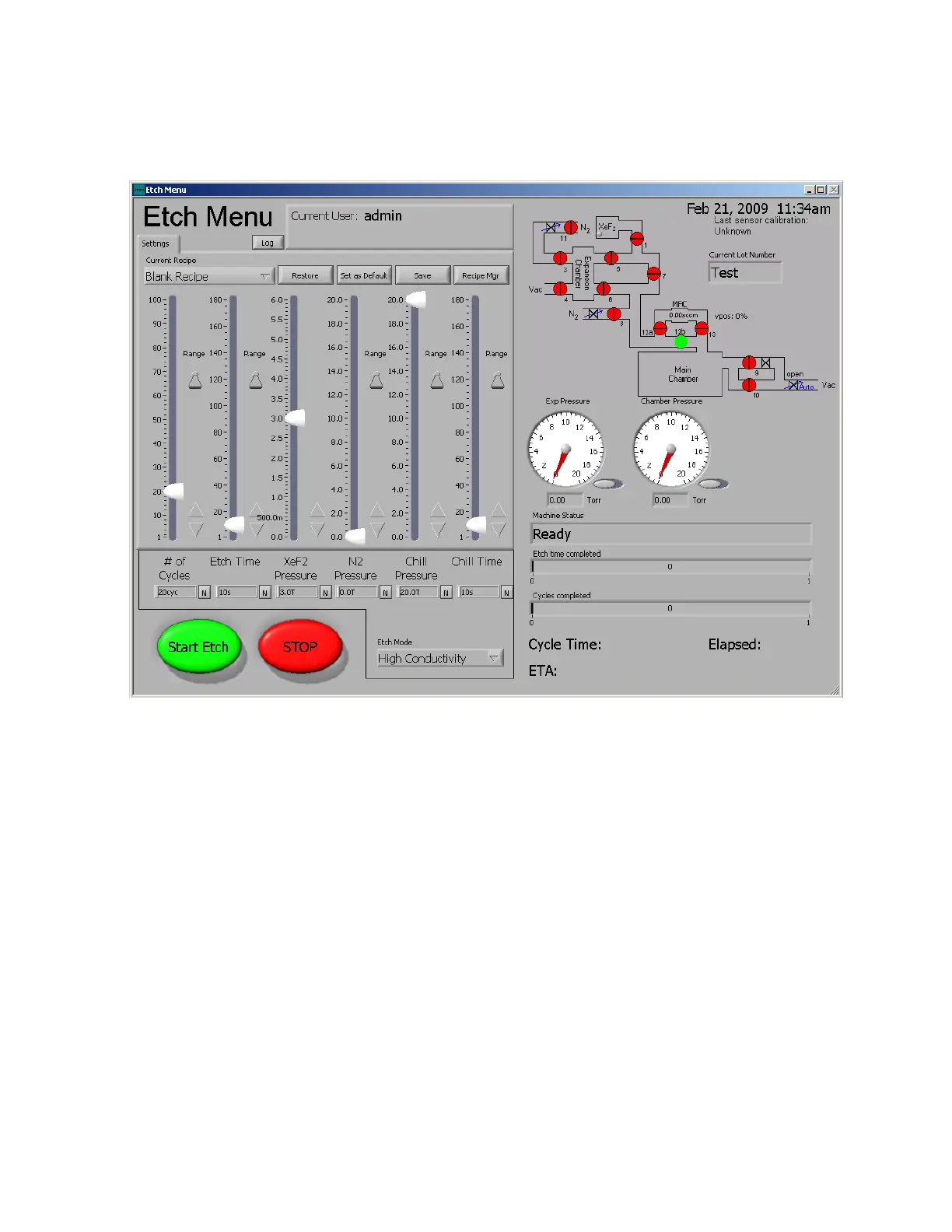

5.3.8 Performing an Etch in the High Conductivity Mode

The operation of the e1 Series in the high conductivity mode (optional upgrade) is similar to the normal

mode; however in the high conductivity mode, there is the ability to flush the chamber between each

cycle with nitrogen. This flush cools the sample and also helps to flush effluents through the chamber

which often help improve etching selectivity and its screen is shown below:

5.3.8.1 High Conductivity Mode Etching Variables

Number of cycles

Since the e1 Series is primarily a pulsed xenon difluoride etching system, the duration of the etch is

controlled by the number of cycles. A cycle consists of the xenon difluoride sublimating to the set

pressure in the expansion chamber, etching for a set amount of time and evacuation of the main

chamber and expansion chamber. Note that there is a range button which changes the slider range for

selecting larger numbers.

Etch Time

When the valve between the main chamber and expansion chamber is opened the pressure

equilibrates and the etching process begins. The etch time is the time between the opening of the valve

between the expansion chamber and the process chamber and the opening of the valve between the

process chamber and the pump. Note that there is a range button which changes the slider range for

selecting larger numbers.

XeF

2

Pressure

In order to introduce the proper amount of xenon difluoride into the main chamber a set pressure

change of xenon difluoride must be delivered to the expansion chamber. Because xenon difluoride has

a vapor pressure of ~4T at room temperature the upper limit for the XeF

2

pressure is approximately 4T.

Loading...

Loading...