Check Check points

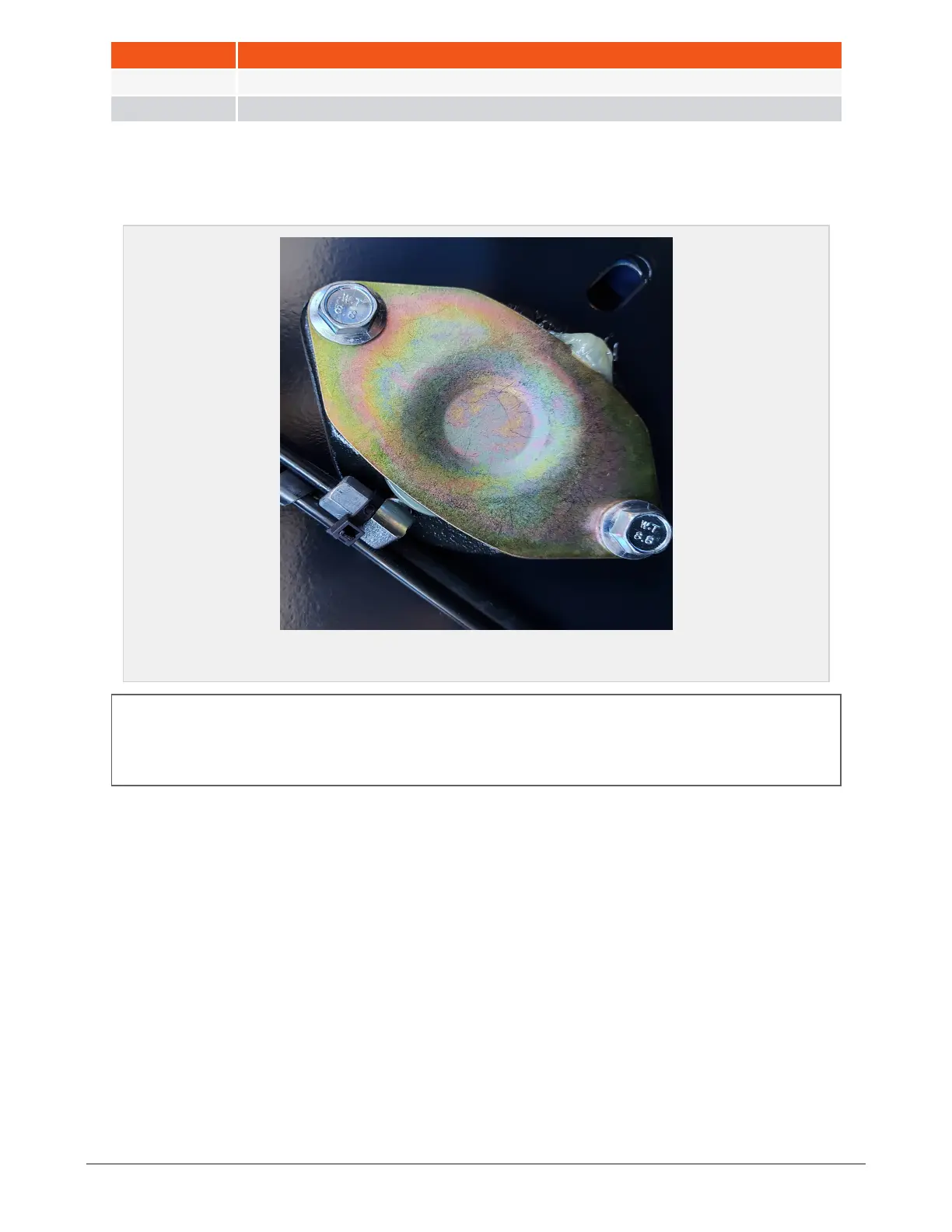

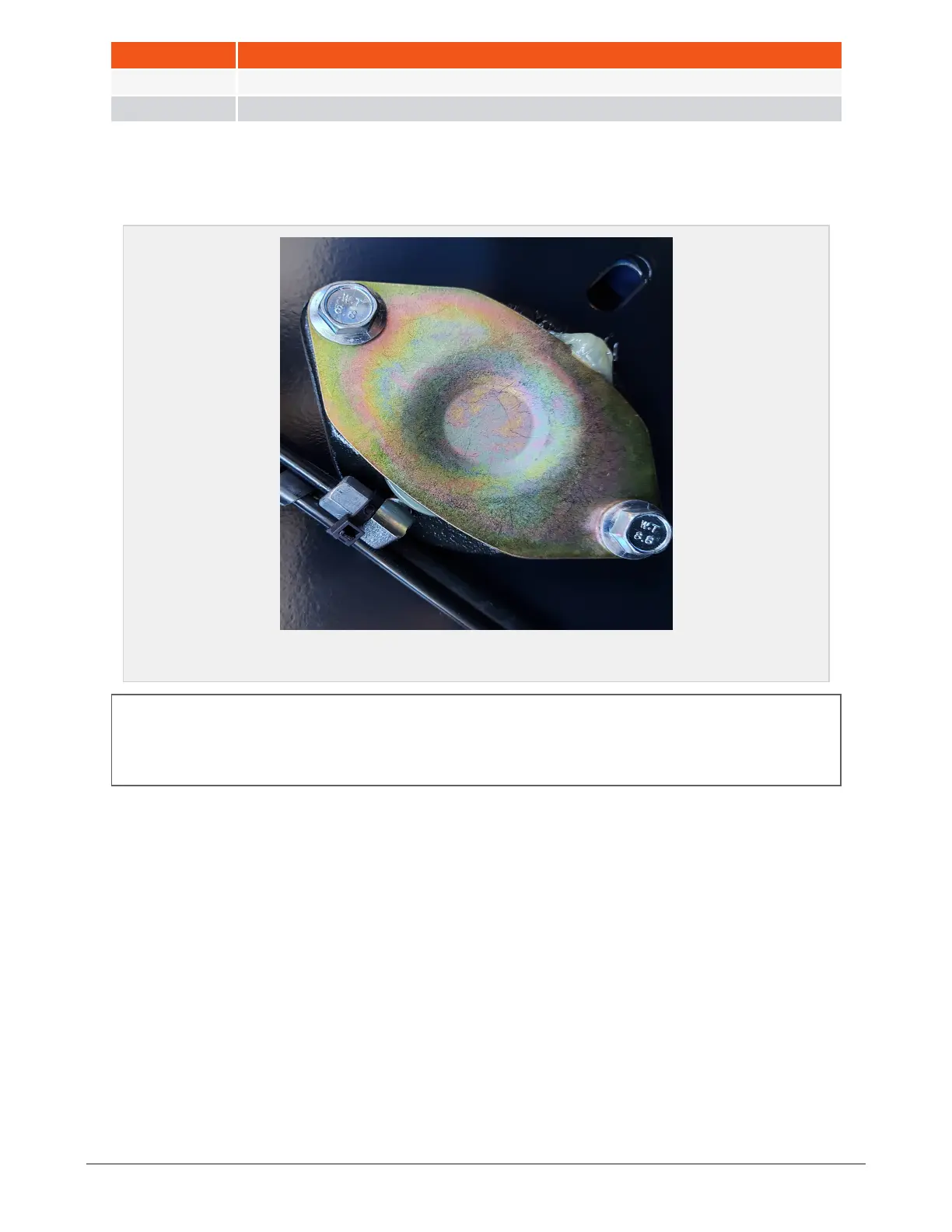

All bearings have a visible grease collar. Figure 2.3

No visible grease on the relief valve on the grease pump.

Precautions: A new compactor must go through a break-in in period. It shouldn’t be run at maximum capa-

city at the first 25 hours of operation. The operator must be observant, monitoring that all functions are

working correctly, and being aware of abnormal sounds from the machinery. Fine tuning of the process

must be carried out, until the compactor has reached its optimum capacity, based on the material being

baled.

Figure 2.3 :

Grease collar on bearings/bushings

NOTE: Slide bearing clearance is tight when the machine is new, and could lead to increased temperature in

the bearings. The slide bearings must be checked frequently during the break-in period. If the temperature is

rising in some of the bearings, activate the manual greaser from the control panel to increase the amount of

grease supplied to bearings.

2 SAFETY 21

Loading...

Loading...