L

--

740

--

28

--

E

6.6 Installing Proper Pipe Supports

If pipeline oscillation is large or for accurate measurement on low flows, take into account the following:

(1) Provide pipe supports in the range shown below preferably with pipes clamped arranged

symmetrically both upstream and downstream of the sensor.

(2) Clamp the pipeline securely without using rubber bushings or similar cushioning material intended

for the absorption of shock and vibration.

(3) While it is necessary that the rigidity of clamps supporting upstream and downstream piping,

pedestal, floor, etc. that hold individual supporting members be sturdy enough to bear their weight,

it is more important to secure and maintain the overall rigidity of the entire structure. In large sized

installations in particular, changes in the spring elements present in the area surrounded by dot lines

in Fig. 6.18 due to exposure to thermal stress, line pressure, shocks, aging, and other contributing

factors can cause zero shifts.

CAUTION: Support the pipeline with hold-down clamps; never hold down the sensor unit.

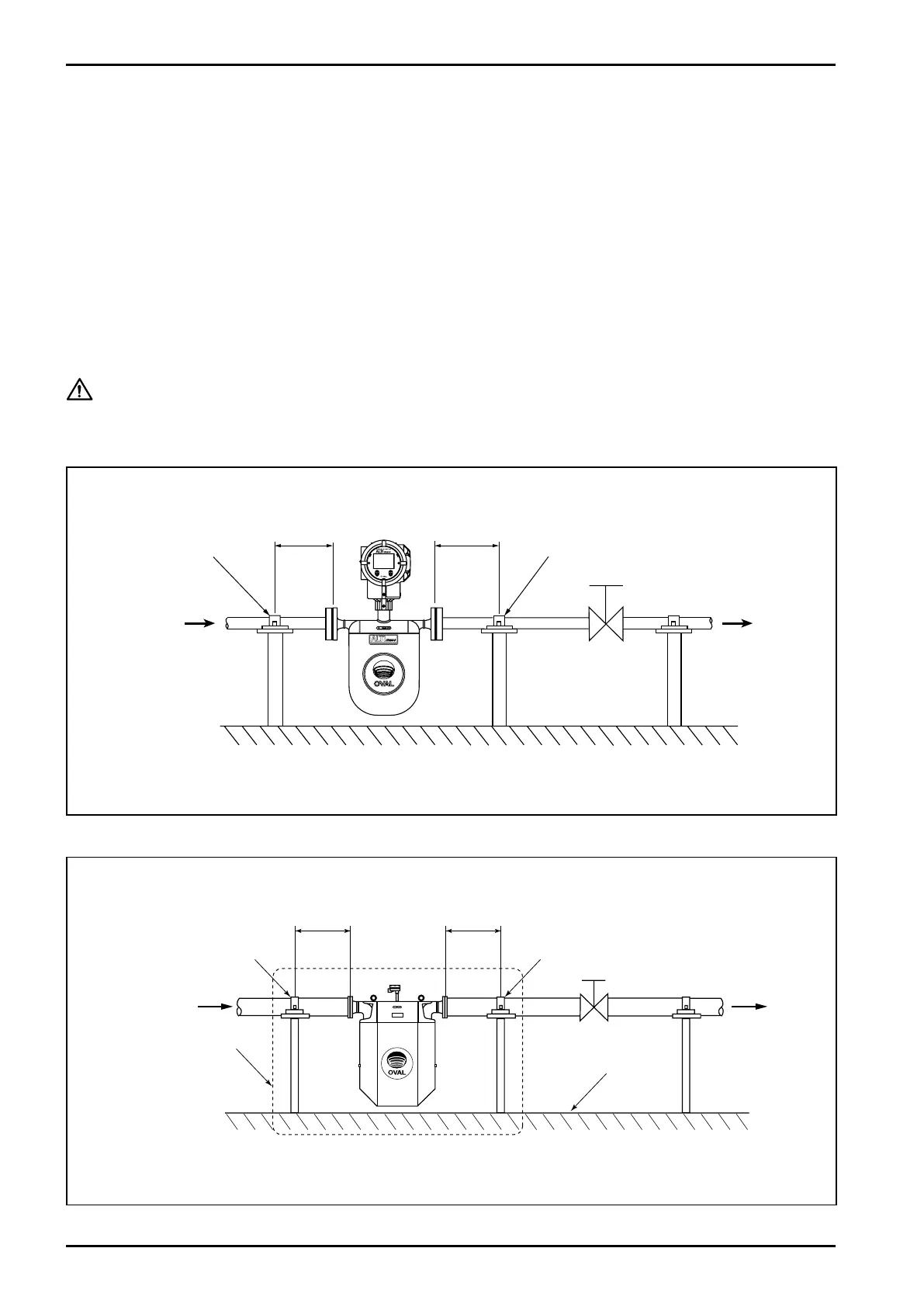

6.6.1 Type U pipe supports

●

CA003 to CA080

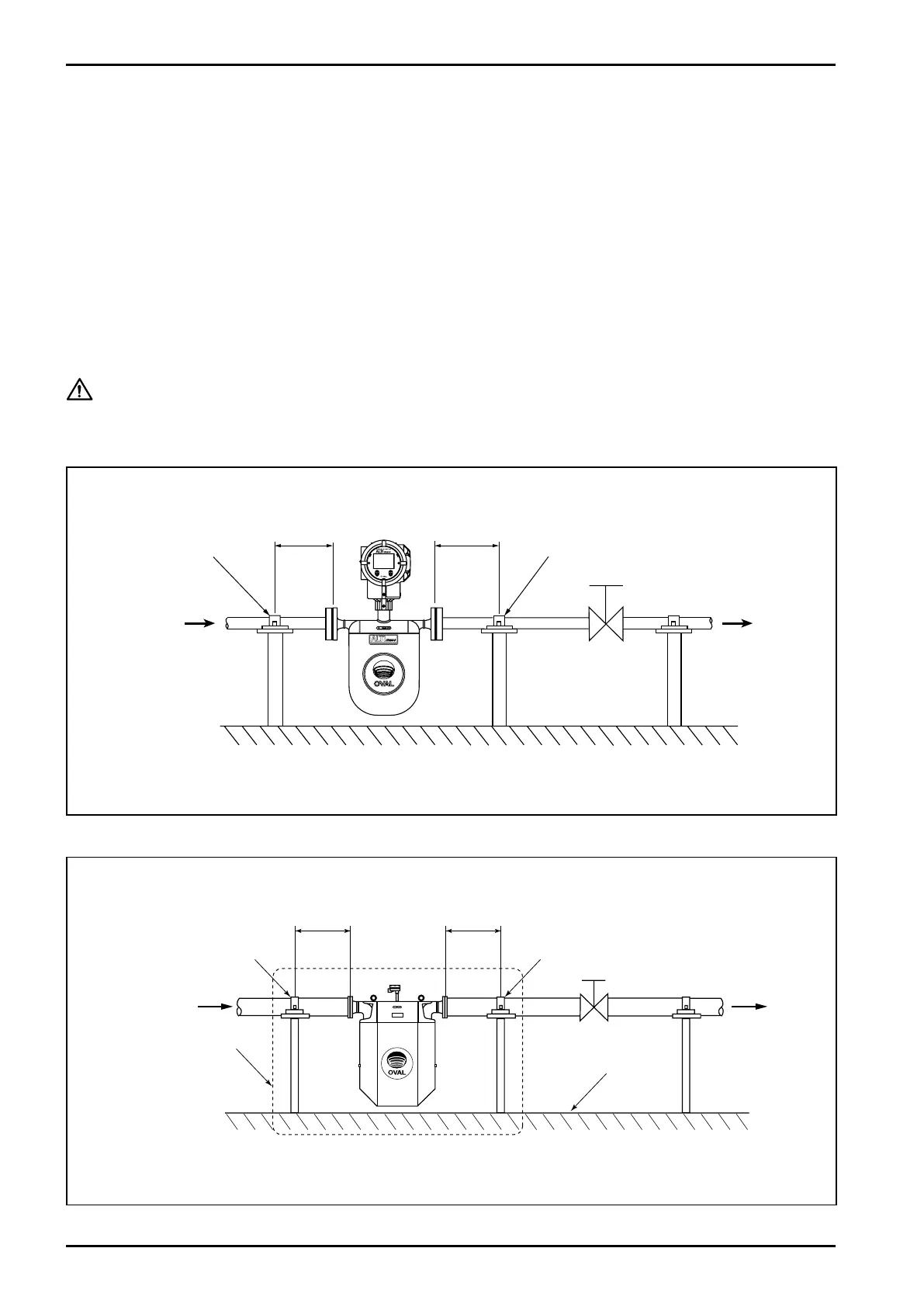

●

CA100 to CA250

Fig.6.17

Fig.6.18

3 to 20D

3 to 20D

Pipe support

IN OUT

Pipe support

Valve

Pipe support

Pipe support

1.5 to 10D

OUTIN

Valve

D: Nominal pipe size

High rigidity of structure

in the area surrounded

by dot lines is desirable.

Pedestal or floor

D: Nominal pipe size

1.5 to 10D

Loading...

Loading...