L

--

740

--

28

--

E

11

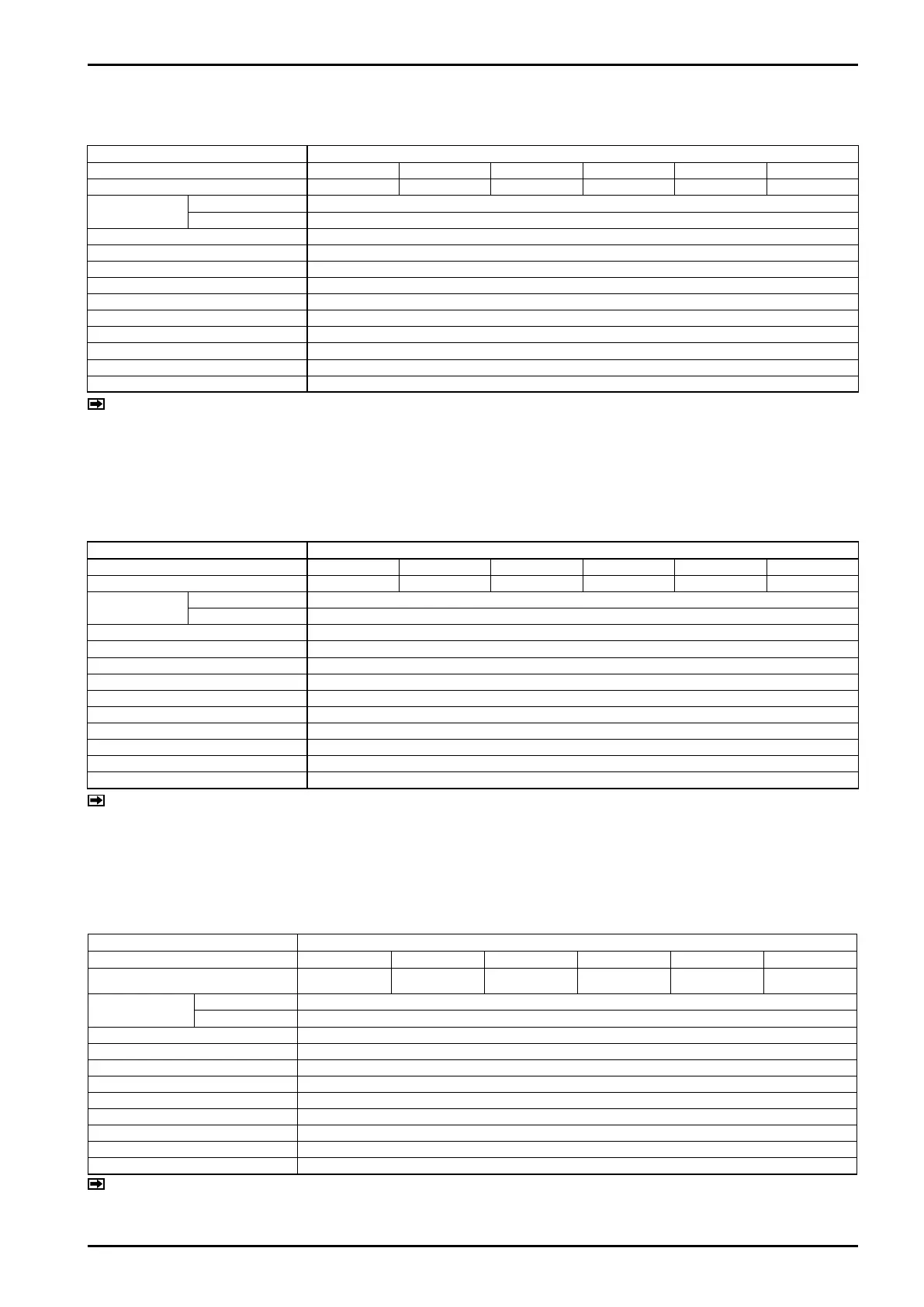

Item Description

Model CS010 CS015 CS025 CS040 CS050 CS080

Nominal flange size

15mm or 1/2" 15mm or 1/2" 25mm or 1"

40mm or 1・1/2"

50mm or 2" 80mm or 3"

Materials

Wetted parts SUS316L

Housing SUS304

Process connection JIS 10, 20K RF / ASME (JPI) 150 RF, IDF ferrule

Acceptable fluid Liquid

Density range 0.5 to 1.0g/mL, 0.7 to 1.3g/mL, 1.0 to 1.5g/mL (※1)

Measurable temperature range

-40 to +130℃ for both integrally and separately mounted types (※2)

Heatproof temperature 150℃ max. (※3)

Max. operating pressure Varies according to process connection.

Sensor housing withstands 2.8MPa

Flow direction Forward / Reverse

Explosionproof configuration

Refer to section 10.4

Dusttight, waterproof configuration

IP66 / 67

3.1.2 Type S sensor unit general specifications

※1: Density range varies with the fluid used.

※2: Refer to section 10.4 for explosionproof specification.

In case of non-explosionproof type, the maximum measurement temperature is 130℃. However, the product

must be used within the maximum ambient temperature of 45℃.

※3: CIP/SIP procedures must be performed within the heatproof temperature range.

※: Temperature class for integral type is T4.

※: For products that are compliant with the High Pressure Gas Safety Act, consult OVAL.

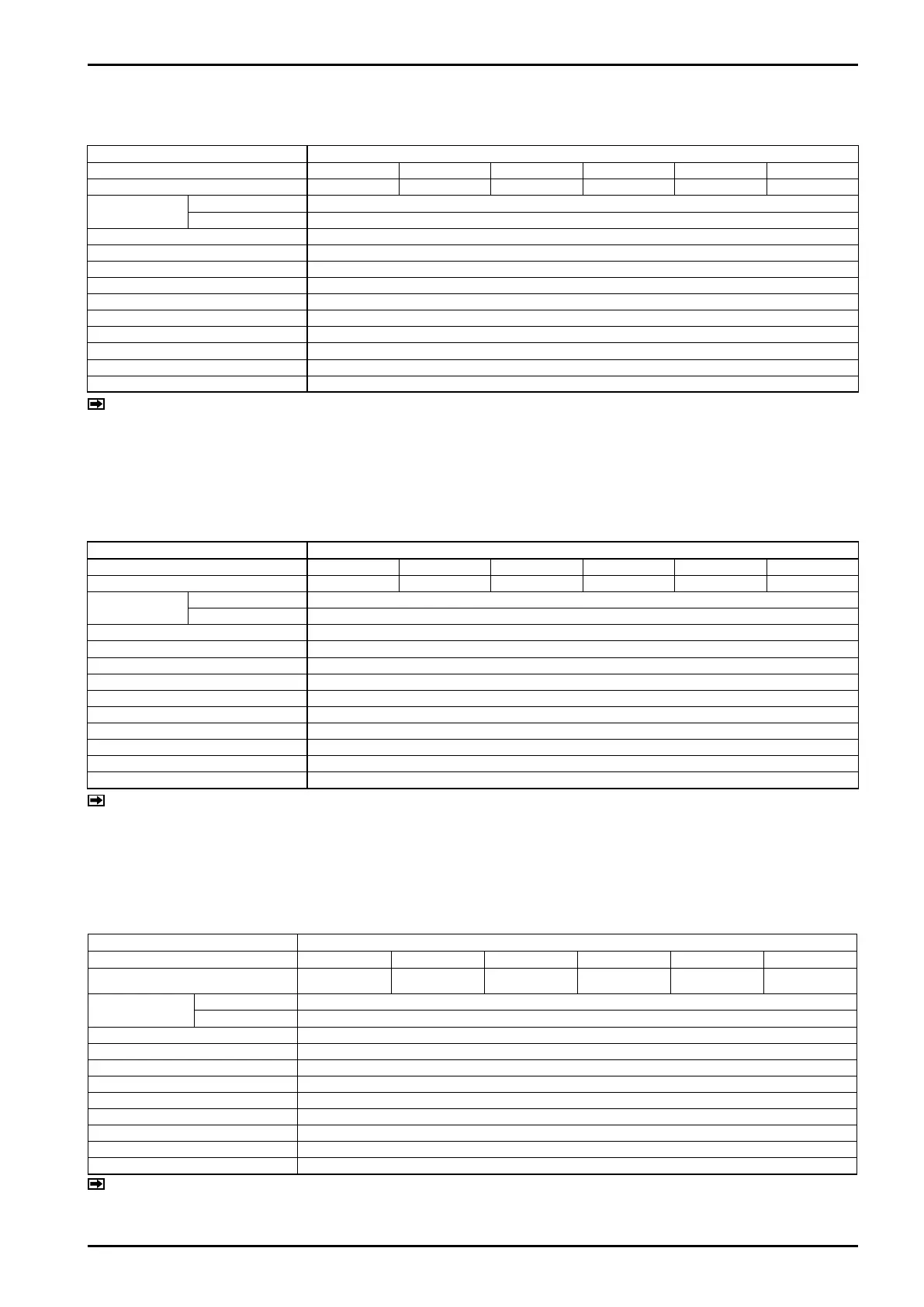

3.1.3 Type B sensor unit general specifications

Item Description

Model CB006 CB010 CB015 CB025 CB040 CB050

Nominal flange size

10mm

or 1/2"

15mm

or 1/2"

15mm

or 1/2"

25mm

or 1"

40mm

or 1・1/2"

50mm

or 2"

Materials

Wetted parts SUS316L

Housing SUS304

Process connection JIS 10, 20, 30K / ASME (JPI) 150, 300, 600 RF, IDF ferrule

Acceptable fluid Liquid

Density range 0.3 to 2.0g/mL

Measurable temperature range

-

40 to +125°C (※1)

Heatproof temperature 150℃ max. (※2)

Max. operating pressure Varies according to process connection.

Flow direction Forward / Reverse

Explosionproof configuration

Refer to section 10.4

Dusttight, waterproof configuration

IP66 / 67

NOTE

※1:

Refer to section 10.4 for explosionproof specification.

In case of non-explosionproof model, up to 125℃ is permitted. However, the product must be used within

the maximum ambient temperature of 45℃.

※2: CIP/SIP procedures must be performed within the heatproof temperature range.

NOTE

※1: Loose flange is applied. Ferrule connections of models CS010 and CS015 comply with ISO2852.

※2: Density range varies with the fluid used.

※3:

Refer to section 10.4 for explosionproof specification.

In case of non-explosionproof models, the maximum measurement temperature of integrally mounted

type is 130℃. However, the product must be used within the maximum ambient temperature of 45℃.

※4: CIP/SIP procedures must be performed within the heatproof temperature range.

※: Temperature class for integral type is T4.

※: If polished wetted parts are desired, contact OVAL.

●

Stainless steel tube type (CS010 to CS080)

Item Description

Model CS010 CS015 CS025 CS040 CS050 CSR50

Nominal flange size

10mm or 1/2" 15mm or 1/2" 25mm or 1"

40mm or 1・1/2"

50mm or 2" 80mm or 3"

Materials

Wetted parts SB338 Grade-9+TB480H

Housing SUS304

Process connection JIS 10, 20K / ASME (JPI) 150 / IDF ferrule (※1)

Acceptable fluid Liquid

Density range 0.5 to 1.0g/mL, 0.7 to 1.3g/mL, 1.0 to 1.5g/mL (※2)

Measurable temperature range -40 to +130℃ (※3)

Heatproof temperature 150℃ max. (※4)

Max. operating pressure Varies according to process connection.

Sensor housing withstands 2.8MPa

Flow direction Forward / Reverse

Explosionproof configuration

Refer to section 10.4

Dusttight, waterproof configuration

IP66 / 67

NOTE

●

Titanium tube type (CS010 to CSR50)

Loading...

Loading...