ENGINE TIMING 17D

Engine timing

To check the timing of the fuel injection

pump17D-03

Special tools:

Universal timing tool, MS.67B

Gear adaptor for use with MS.67B, PD.67-3

Piston probe, PD.221

Caution: This procedure must be followed carefully

if:

• The engine performance is not correct

• The locking screw is released after the fuel

injection pump is removed from the engine.

1Remove the fuel injection pump, operation

20D-06.

Caution: When the pump is held in a vice, do not

apply pressure to the alloy components.

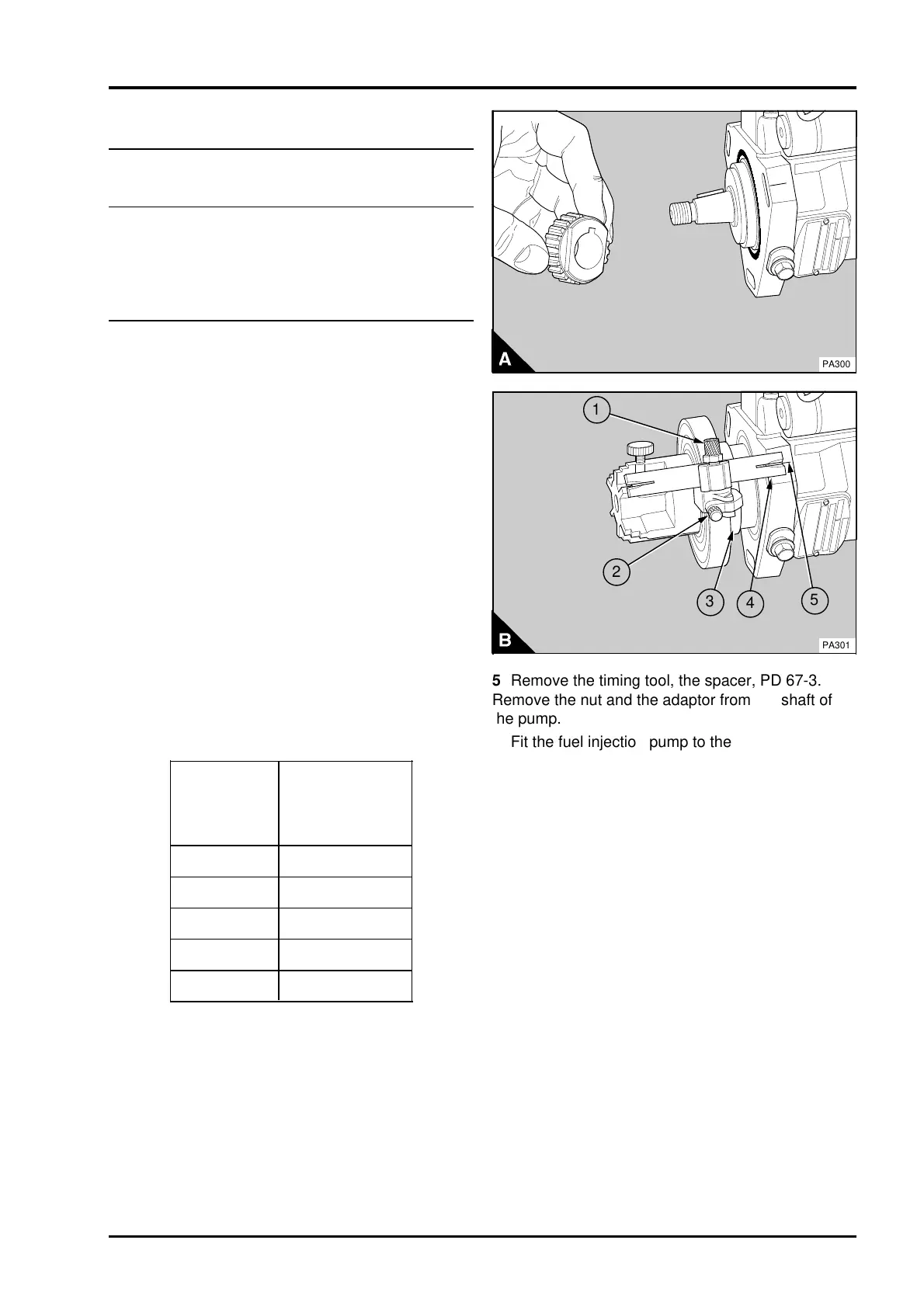

2 Hold the pump securely. Fit adaptor, PD.67-3,

(A) for the timing tool, MS.67B, to the drive shaft of

the pump. Use the nut for the drive gear, tightened

finger tight only, to retain the adaptor.

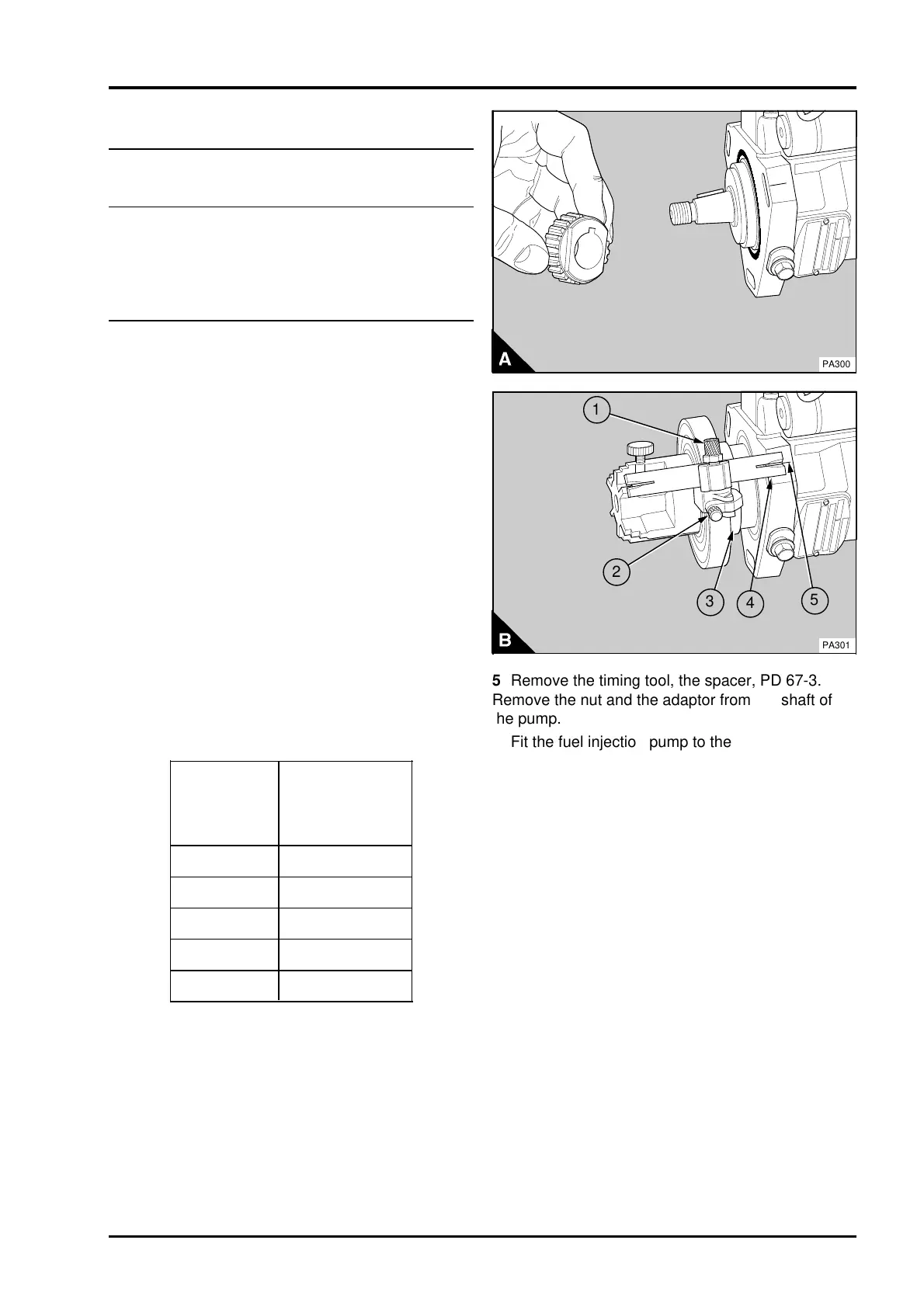

3 Loosen the screw (B2) on the timing tool and

set the timing tool to the correct angle, see the

table below for the correct angle. Tighten the

screw. This angle is relative to the start of injection

with the piston set at 100° BTDC. Fit the timing

tool, 67B, together with the spacer (B3), to the

adaptor on the pump.

Code letters

for fuel

pumps

Locking angle

(degrees

)

BC 336.5

CC 338.5

EC 337.5

FC 335.5

GC 337

4 Release the screw (B1) and slide the pointer

(B4) forward until it is over the centre of the pump

flange and tighten the screw.

Note: If the mark (B5) on the fuel pump flange is

not accurately aligned with the slot in the pointer of

the timing tool the timing of the pump must be

checked by the nearest Perkins Distributor.

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

PA300

4

3

a

a

2

1

a

a

5

PA301

5 Remove the timing tool, the spacer, PD 67-3.

Remove the nut and the adaptor from the shaft of

the pump.

6 Fit the fuel injection pump to the engine,

operation 20D-06.

Note: If the fuel pump was removed because the

engine performance was not correct, operate the

engine and check if the performance has improved.

If the performance is not correct, remove the fuel

pump to the nearest Perkins Distributor.

Perkins Phaser/1000 Series, April 1995 17D.03

Loading...

Loading...