20A FUEL SYSTEM

To remove

Caution: Disconnect the battery before the fuel

injection pump is removed from the engine.

1Remove the rocker cover, operation 12A-01.

2 Remove the atomisers together with their seat

washers, operation 20A-02.

3 Rotate the crankshaft clockwise, from the front,

until the push rod for the inlet valve of number 2

cylinder just releases.

Caution: Do not rotate the crankshaft, except in

accordance with paragraph five, when the piston

position probe is fitted to the engine.

4 Ensure the seat washer from number 2 cylinder

has been removed and put the piston position

probe, PD.221 (A1) into the position for the number

2 cylinder. Fit the atomiser clamp to the probe and

tighten the setscrews gradually and evenly. The

piston position probe is used to set the crankshaft

to 100° BTDC.

5 Slowly rotate the crankshaft clockwise, from the

front, until the piston just contacts the piston

position probe. The piston will now be set at 100°

BTDC on the compression stroke of number 2

cylinder.

Caution: Ensure that the piston comes lightly into

contact with the piston position probe, or both the

piston and the probe could be damaged.

6 Loosen the locking screw and pull out the spacer

between the locking screw and the pump body.

Tighten the locking screw to 27 Nm (20 lbf ft)

2,8 kgf m. Ensure that the spacer is not lost. It is

recommended that the spacer is fitted to the pump

body by locking wire.

Caution: Do not release the clamp of the KSB cold

start device, if one is fitted.

7 Remove the low pressure pipes and cables from

the fuel pump.

8 Remove the setscrew and the nut of the support

bracket below the fuel pump.

9 Release the setscrews and remove the gear

cover from the timing case cover. It may be

necessary to carefully hit the cover with a soft

faced hammer to release it.

Release the flange nuts of the pump three or four

turns.

Remove the nut, washer and the spacer (early

Phaser 210Ti engines only) from the drive gear for

the pump.

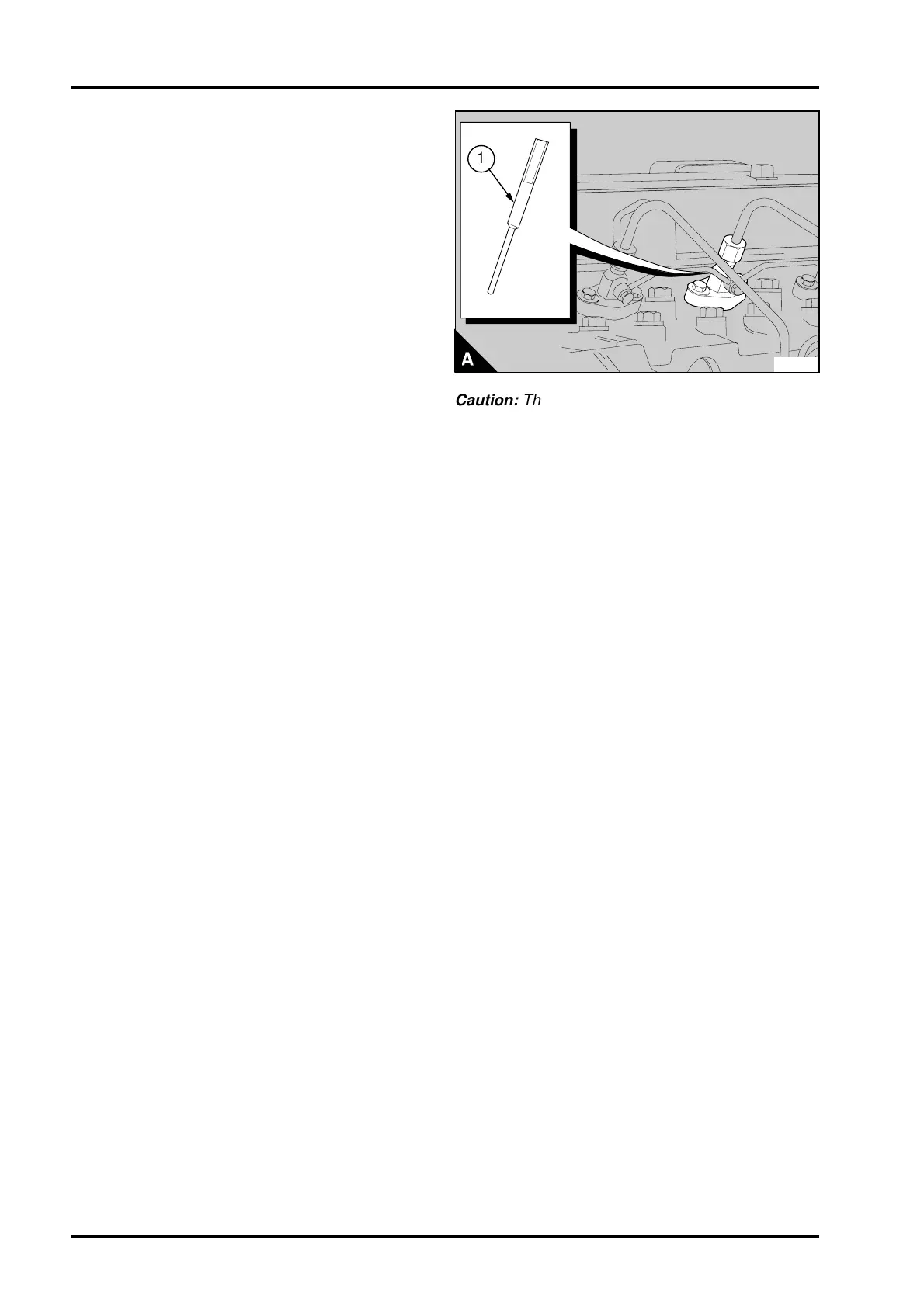

Fit the gear puller PD.155C and loosen the gear on

the drive shaft of the pump. If the holes for the

puller adaptors in the fuel pump gear are not in the

correct position to fit the puller it may be necessary

to remove the water pump, operation 21A-03.

PA257A

a

a

1

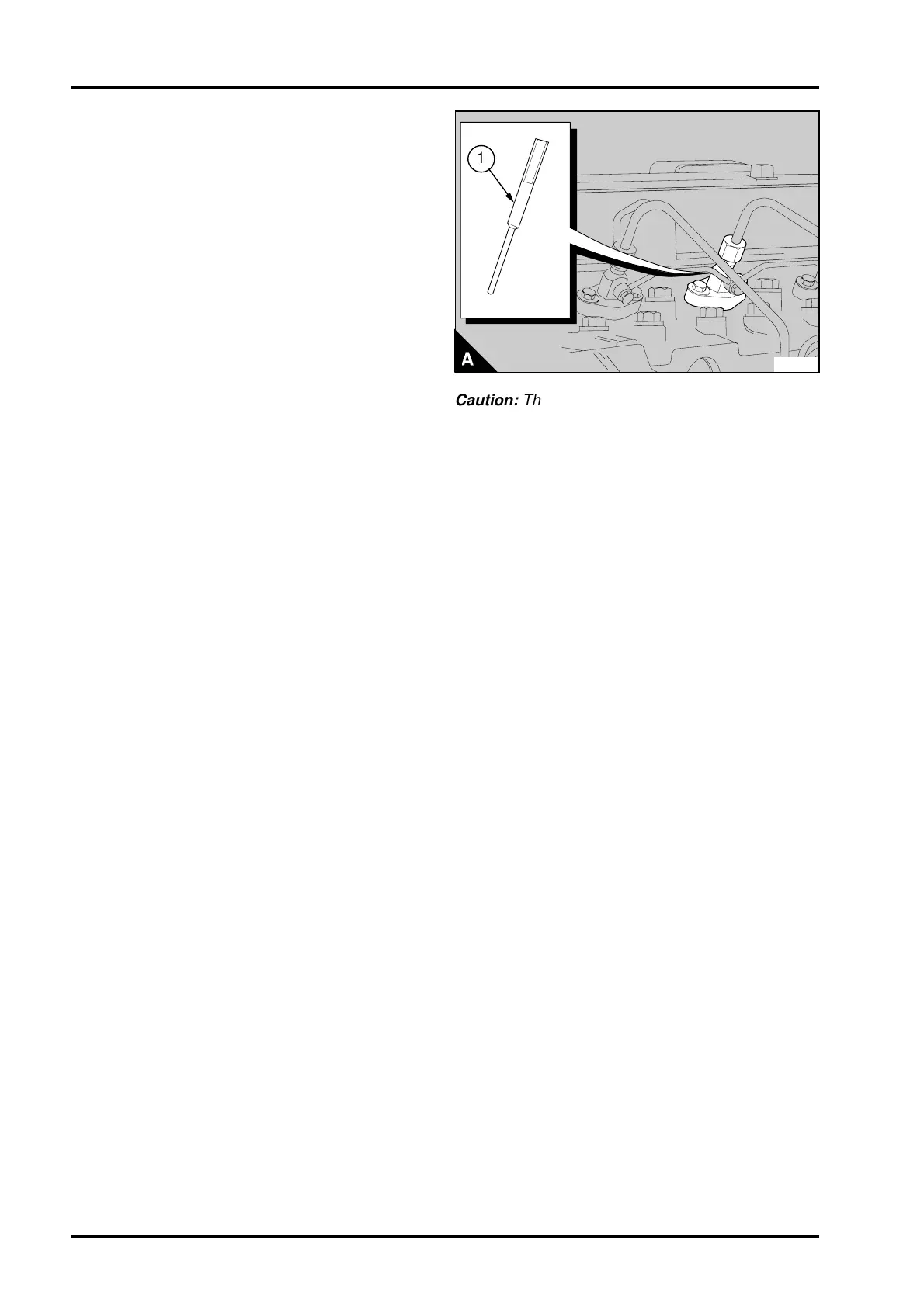

Caution: The crankshaft must not be moved when

the pump is not on the engine. Movement of the

crankshaft may result in damage to the timing case

and make it necessary to time the engine before

the pump can be fitted.

9 Remove the pump from the engine.

Caution: The fuel injection pump must be set in

accordance with the procedure on page 20A.17:

• The pump is to be renewed

• The pump performance is not correct

• The locking screw is released after the pump is

removed from the engine.

20A.14 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...