COOLING SYSTEM 21

Do not lubricate the seal. It is important that the

seal is not contaminated by oil or grease. If it is

held in the hand, it should be held by the edge of

the flange. Do not damage the ring of green sealant

applied to the body of the coolant seal just behind

the flange of the seal.

Support the pulley end of the shaft, put the seal

into position on the end of the shaft. Ensure that

the ring of sealant is towards the bearings. Use the

tool to press the seal onto the shaft until the bottom

of the seal flange is in complete contact with the

pump body. Continue to apply force for

approximately ten seconds to ensure that the seal

remains in position when the force is released.

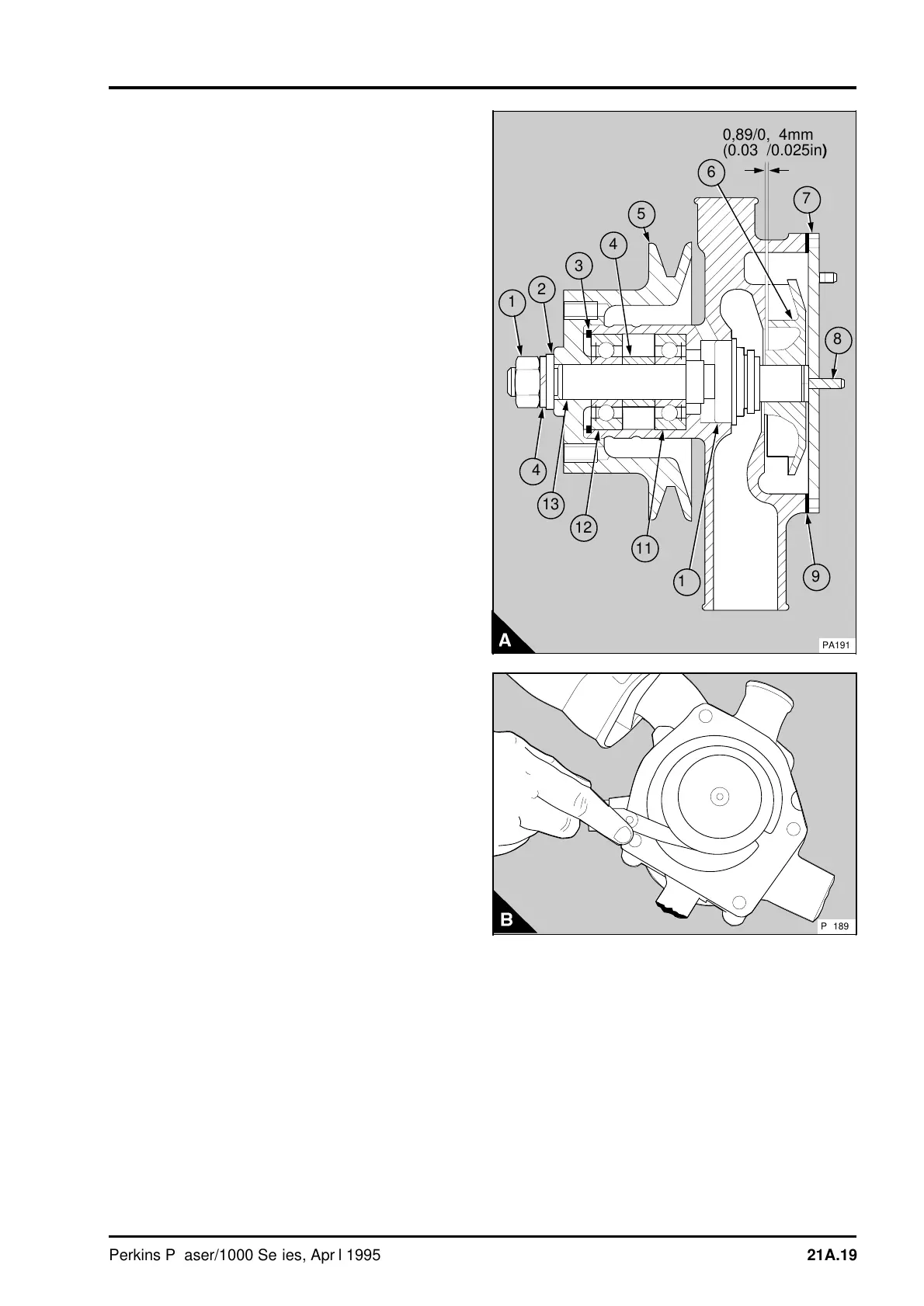

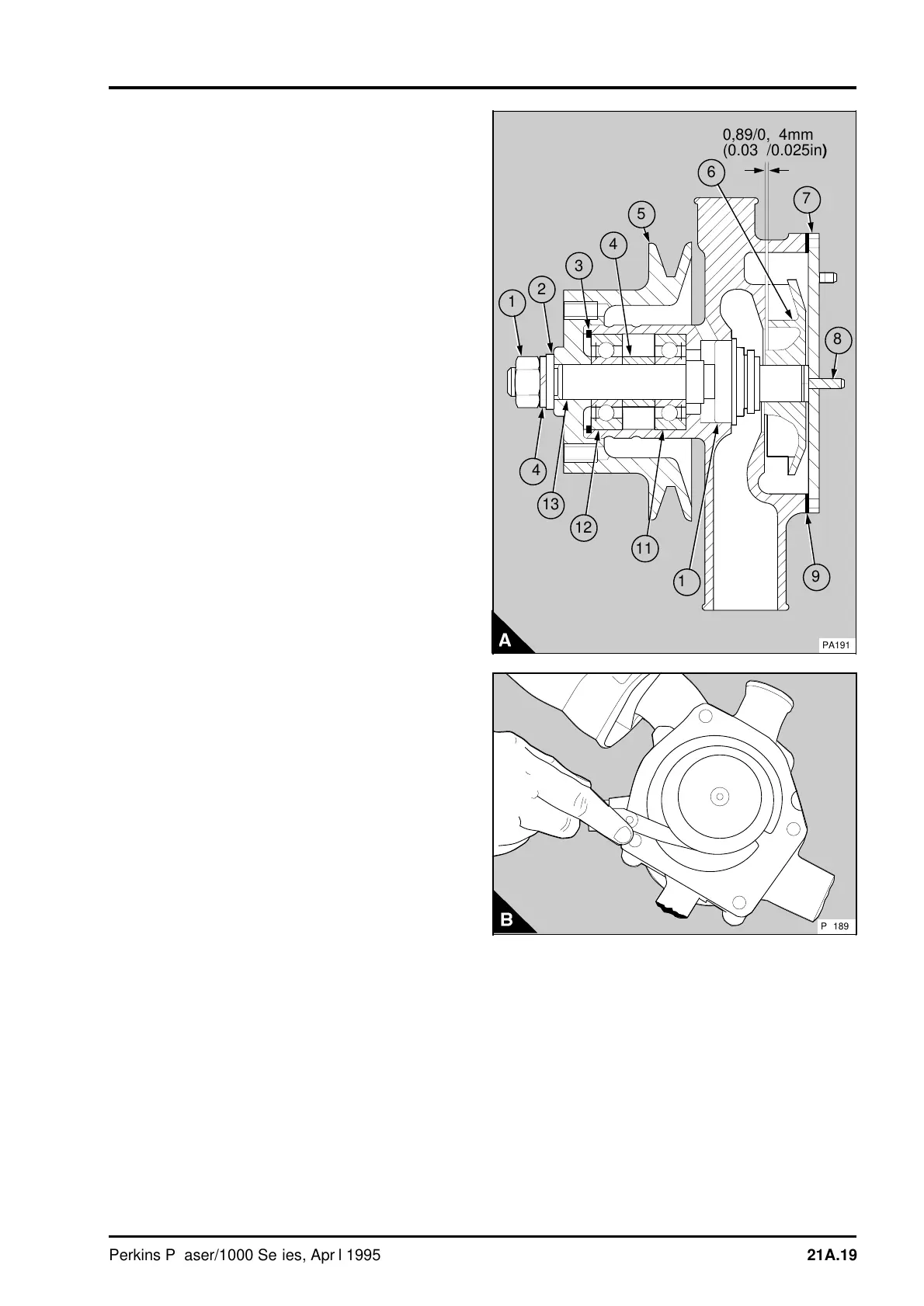

7 Support the pulley end of the shaft and press the

impeller onto the shaft until the clearance (A)

between the impeller blades and the pump body is

0,64/0,89 mm (0.025/0.035 in). The clearance can

be checked with a feeler gauge (B)

Rotate the shaft to ensure that the impeller is free.

8 Put the plain washer (A2) and the spring washer

(A14) in position onto the pulley. Fit the nut and

tighten it to 82 Nm (60 lbf ft) 8,3kgf m.

9 Renew the joint for the blanking plate and fit the

the blanking plate to the pump body. Ensure that

the mark on the pump body is aligned with the line

on the blanking plate and that the two studs (A8) for

the adjustment bracket are at the rear of the plate .

1

2

3

4

a

a

a

5

a

a

6

a

a

7

9

a

a

a

a

14

a

a

a

a

a

a

13

a

a

a

a

12

a

a

a

a

a

a

11

a

a

a

a

10

a

a

8

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

0,89/0,64mm

(0.035/0.025in)

PA191

PA189

Perkins Phaser/1000 Series, April 1995 21A.19

Loading...

Loading...