FLYWHEEL AND FLYWHEEL HOUSING 22

Flywheel

To remove and to fit22A-01

Warning! The flywheel is heavy, use lift equipment

or get help to assist with the lift operation before

removal of the flywheel fasteners.

To remove

1 Remove two opposite setscrews from the

flywheel and fit temporarily two guide studs to

ensure safety when the flywheel is removed and

fitted.

2 Remove the remainder of the setscrews and

washers and remove the flywheel.

3 Check the flywheel and ring gear for damage and

renew, if necessary.

To fit

1 Ensure that the location faces of the crankshaft

and the flywheel are clean and free from damage.

2 Fit the flywheel over the guide studs. Fit four

setscrews and their washers. Remove the guide

studs and fit the remainder of the setscrews and

the washers. Tighten the setscrews to 105 Nm

(77 lbf ft) 10,7 kgf m.

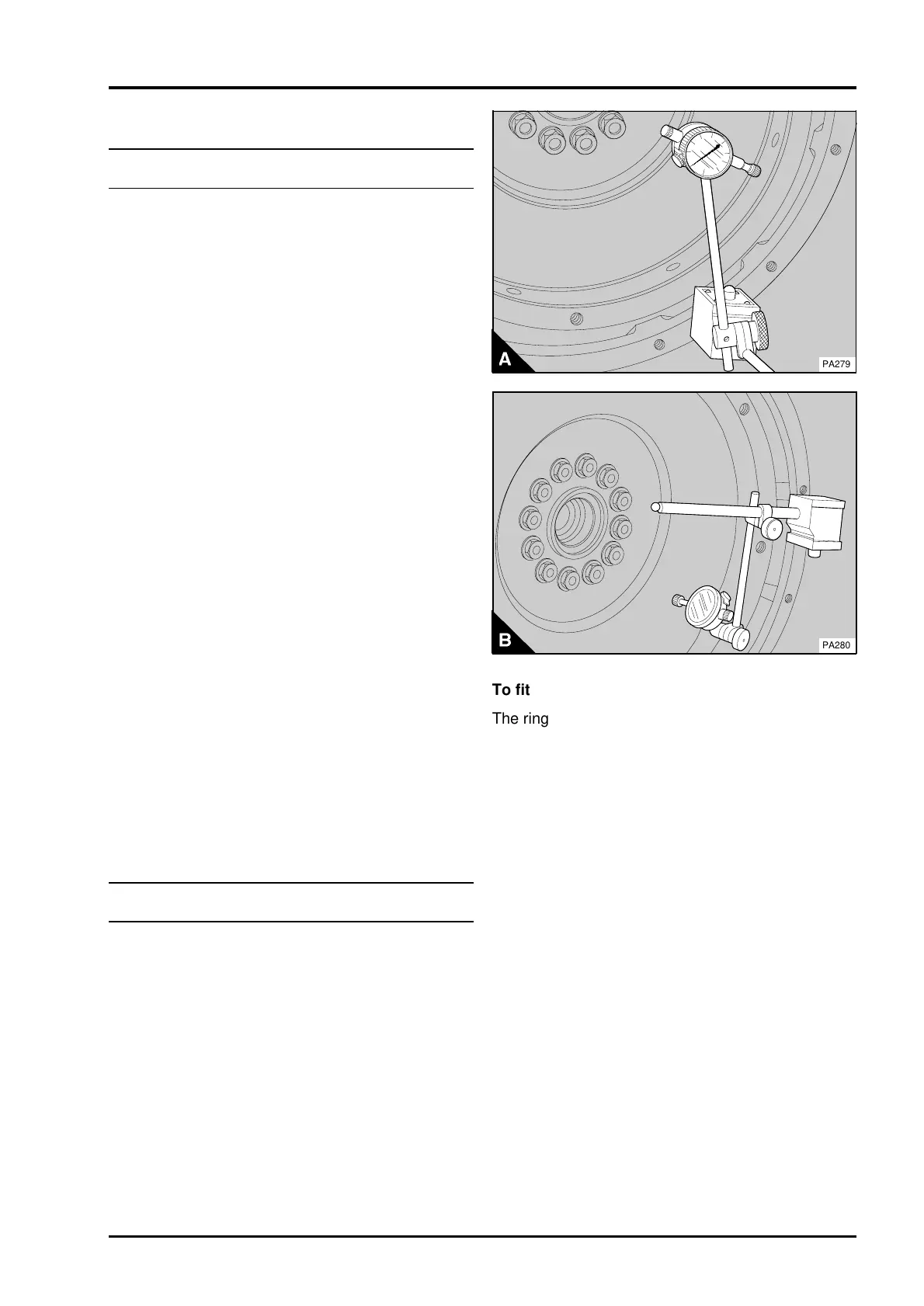

3 Check the flywheel run-out with a dial test

indicator (A). This must be less than 0,30 mm

(0.012 in) total indicator reading.

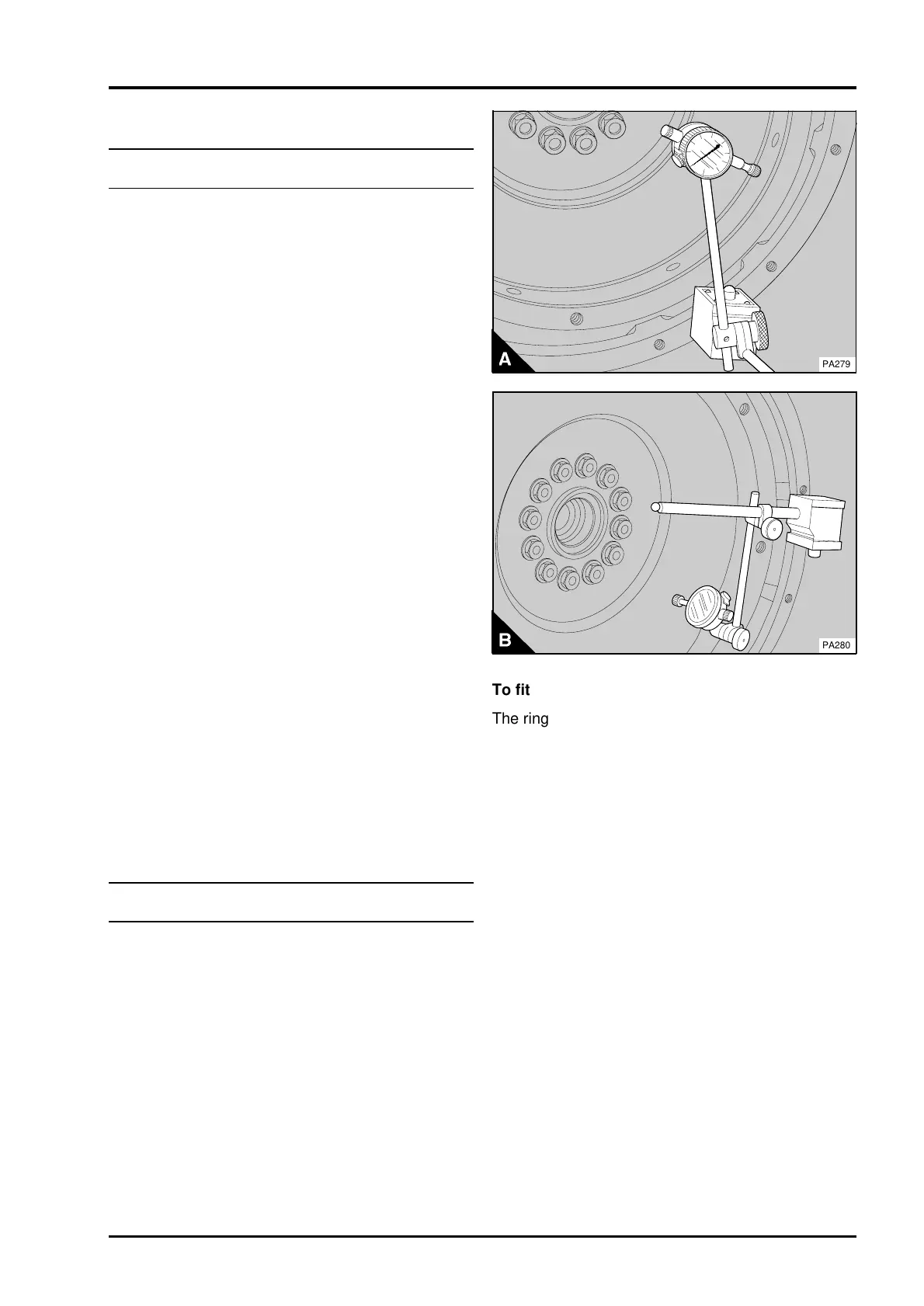

4 Check the alignment of the flywheel face (B).

The error in alignment must not be more than 0,03

mm (0.001 in) total indicator reading for every

25 mm (1.0 in) of the flywheel radius from the

crankshaft axis to the indicator plunger. During this

check, keep the crankshaft pressed toward the

front to remove the effect of crankshaft end-float.

Ring gear

To remove and to fit22A-02

To remove

Warning! wear eye protection during this operation.

Before the ring gear is removed, check the position

of the chamfer on the teeth.To remove the ring

gear use a hammer and a chisel to break the ring.

Ensure that the flywheel is not damaged during this

operation.

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

PA279

PA280

To fit

The ring gear is heated onto the flywheel. When a

new gear is to be fitted, ensure that it is not heated

to more than 250°C (480°F). Ensure that the

chamfer on the teeth of the gear is in the correct

direction.

Perkins Phaser/1000 Series, April 1995 22A.03

Loading...

Loading...