22 FLYWHEEL AND FLYWHEEL HOUSING

Flywheel housing

To remove and to fit22A-03

Warning! The flywheel housing is heavy, use lift

equipment or get help to assist with the lift

operation before removal of the flywheel housing

fasteners.

To remove

1Remove the starter, operation 23B-01, and the

flywheel, operation 22A-01.

2 Release the housing setscrews and with a soft

face hammer, hit carefully the housing to remove it

from the dowels.

To fit

1 Ensure that the rear face of the cylinder block

and the faces of the housing are clean and free

from damage. Ensure that the location dowels are

fitted correctly. If a felt seal is fitted to the rear

flange of the sump, renew the seal.

2 Fit the housing onto the dowels and tighten

lightly the setscrews.

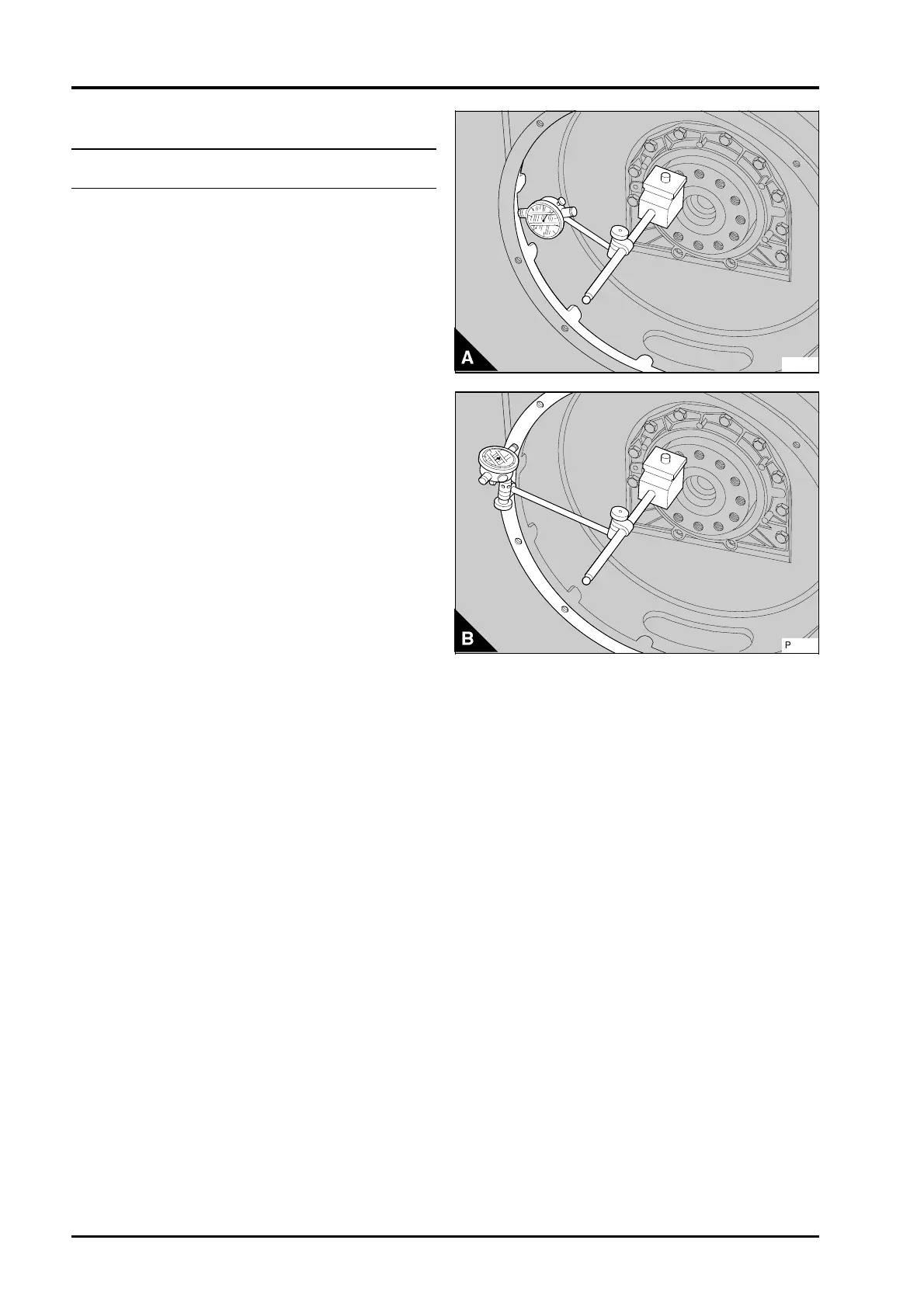

3 Check the housing concentricity with a dial test

indicator (A). The run-out limit is given in the data

and dimensions. If any adjustment is necessary, it

must be made on the housing and the concentricity

checked again.

4 Tighten the setscrews to the torque

recommended in section 11B.

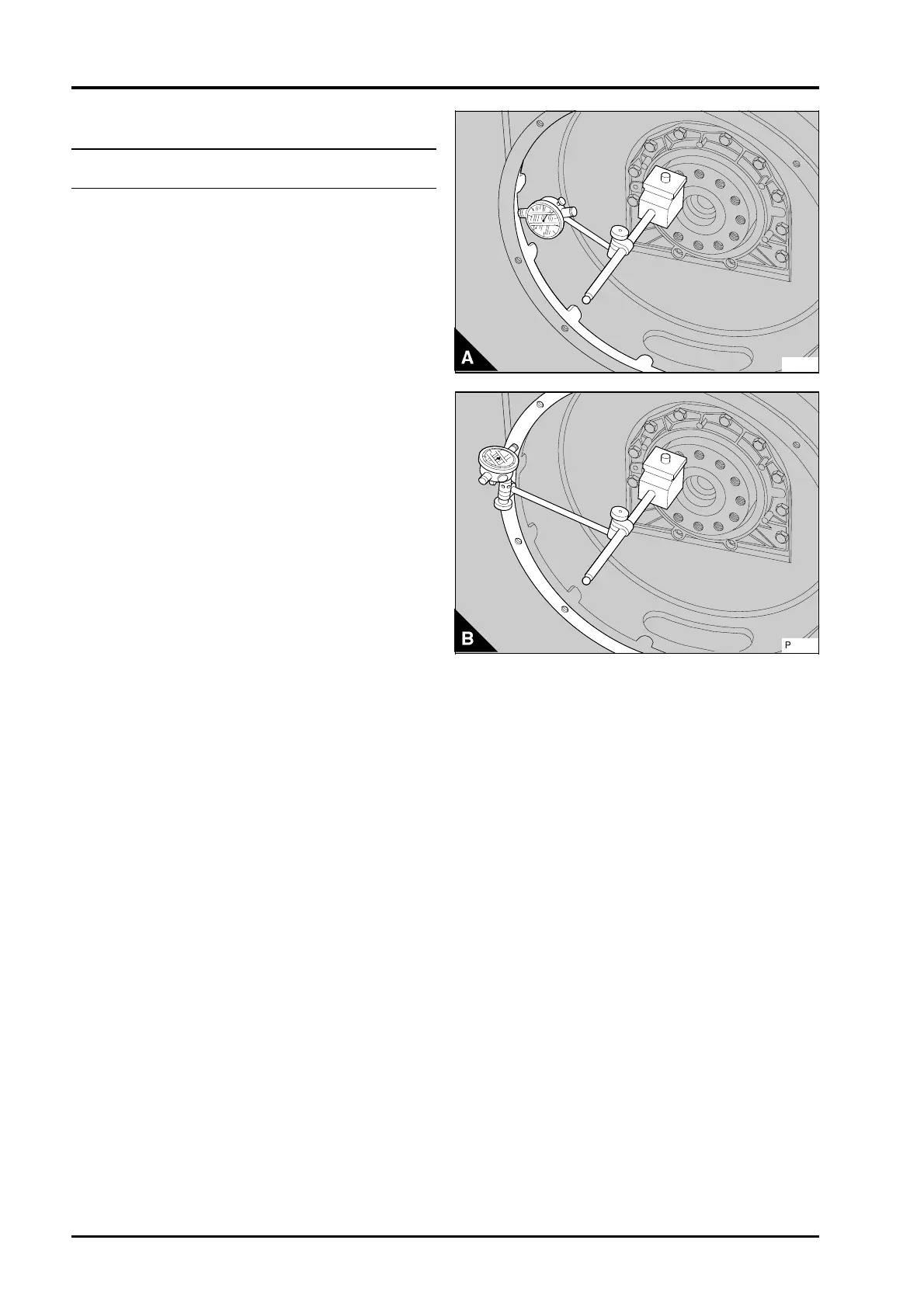

5 Check the housing alignment (B). The maximum

tolerance is given in the data and dimensions. Any

necessary adjustment must be made on the

housing and not on the cylinder block.

6Fit the flywheel, operation 22A-01 and the starter

motor, operation 23B-01.

PA177

PA178

22A.04 Perkins Phaser/1000 Series, April1995

Loading...

Loading...