CYLINDER HEAD ASSEMBLY 12

To fit

Special tools:

Angle gauge, to tighten cylinder head setscrews,

MS.1531

1 Clean the bottom face of the cylinder head and

top face of the cylinder block. Ensure that there is

no debris in the cylinder bores.

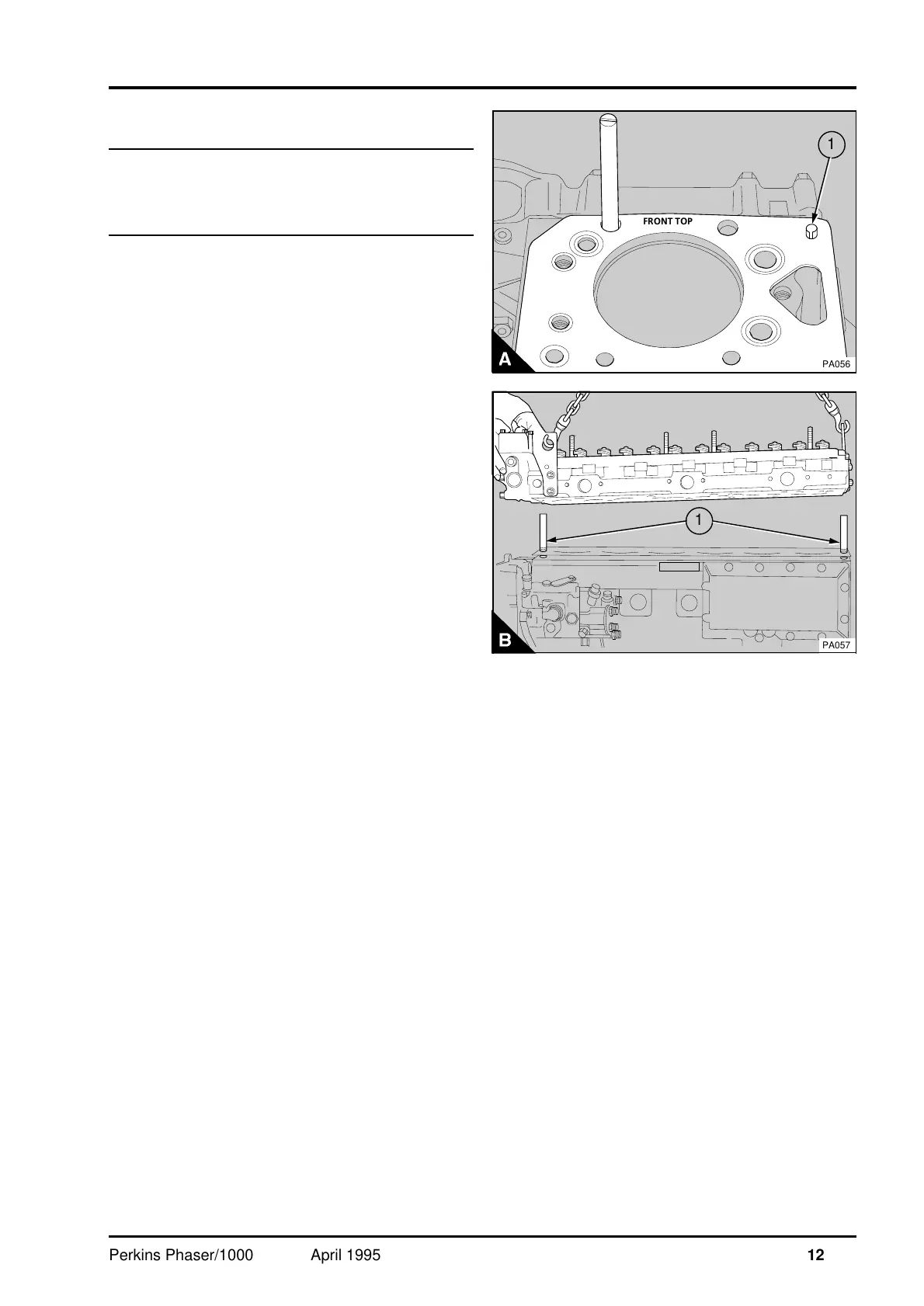

Note: Certain engines have two location pins (A1),

one at each end of the cylinder head, pressed into

the cylinder block to hold the cylinder head gasket

in the correct position before the cylinder head is

fitted.

Caution:

•

To prevent damage to the cylinder head gasket,

ensure that the location pins are

pressed

in the

cylinder block before the cylinder head is fitted.

•

The cylinder head gasket must be fitted without

jointing compound.

2 Put the cylinder head gasket in position; It is

stamped "FRONT TOP" for correct assembly (A).

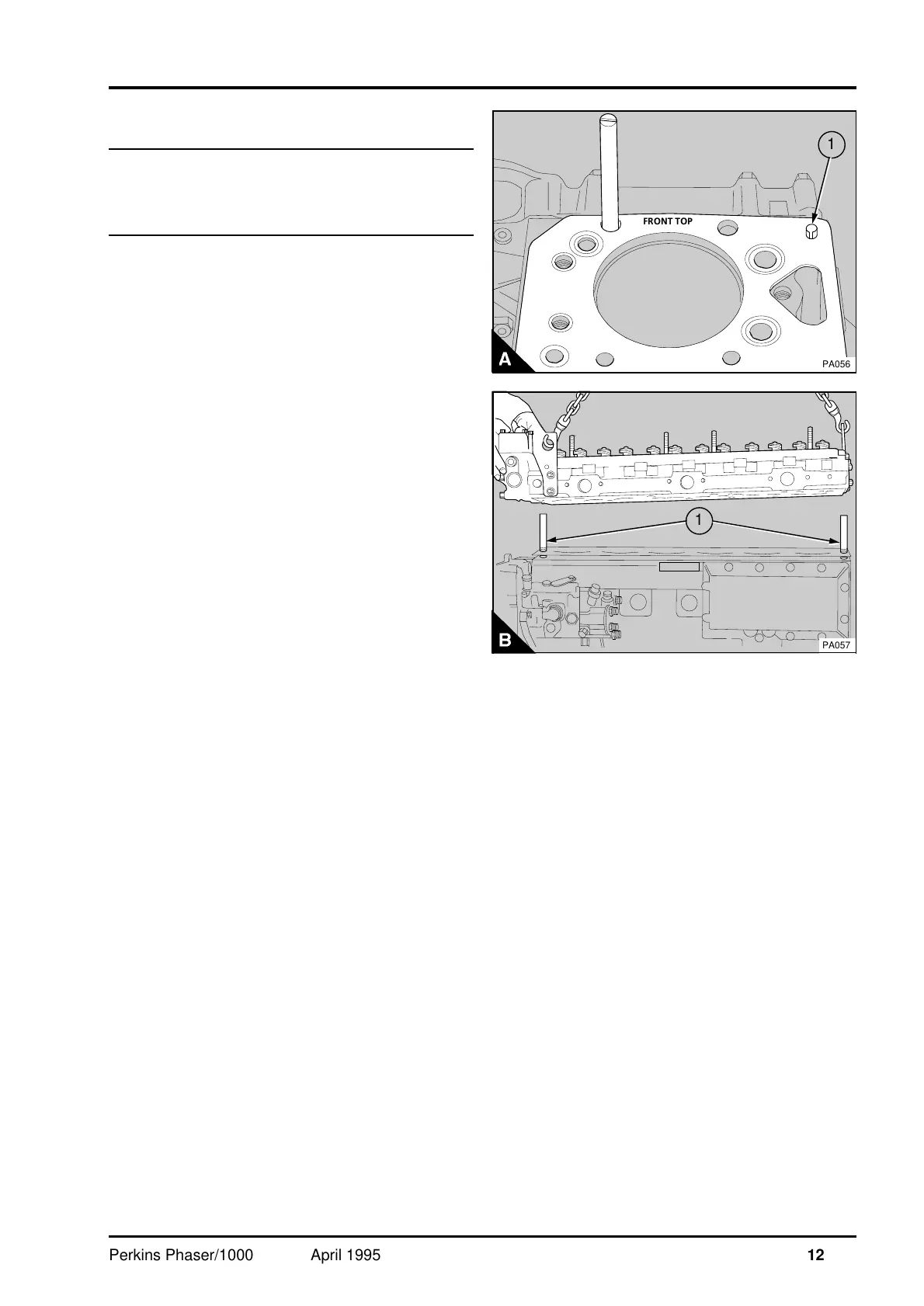

3 To ensure the cylinder head is fitted into the

correct position, fit two suitable 1/2 UNF guide

studs (B1) in positions 15 and 20 (12A.12/B) or

positions 25 and 30 (12A.12/A). Put the cylinder

head in position.

4 Lightly lubricate the threads of the cylinder head

setscrews and the thrust faces of the setscrew

heads. Engage some of the setscrews in their

correct positions and remove the guide studs.

Engage the remainder of the setscrews in their

correct positions.

5 Gradually and evenly tighten the setscrews to

110 Nm (80 lbf ft) 11,1 kgf m in the sequence

shown in (12A.12/A or B).

6 Repeat paragraph 5 to ensure that all the

setscrews are tightened to the correct torque.

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

FRONT TOP

a

a

1

PA056

PA057

a

a

1

Perkins Phaser/1000 Series, April 1995 12A.13

Loading...

Loading...