12 CYLINDER HEAD ASSEMBLY

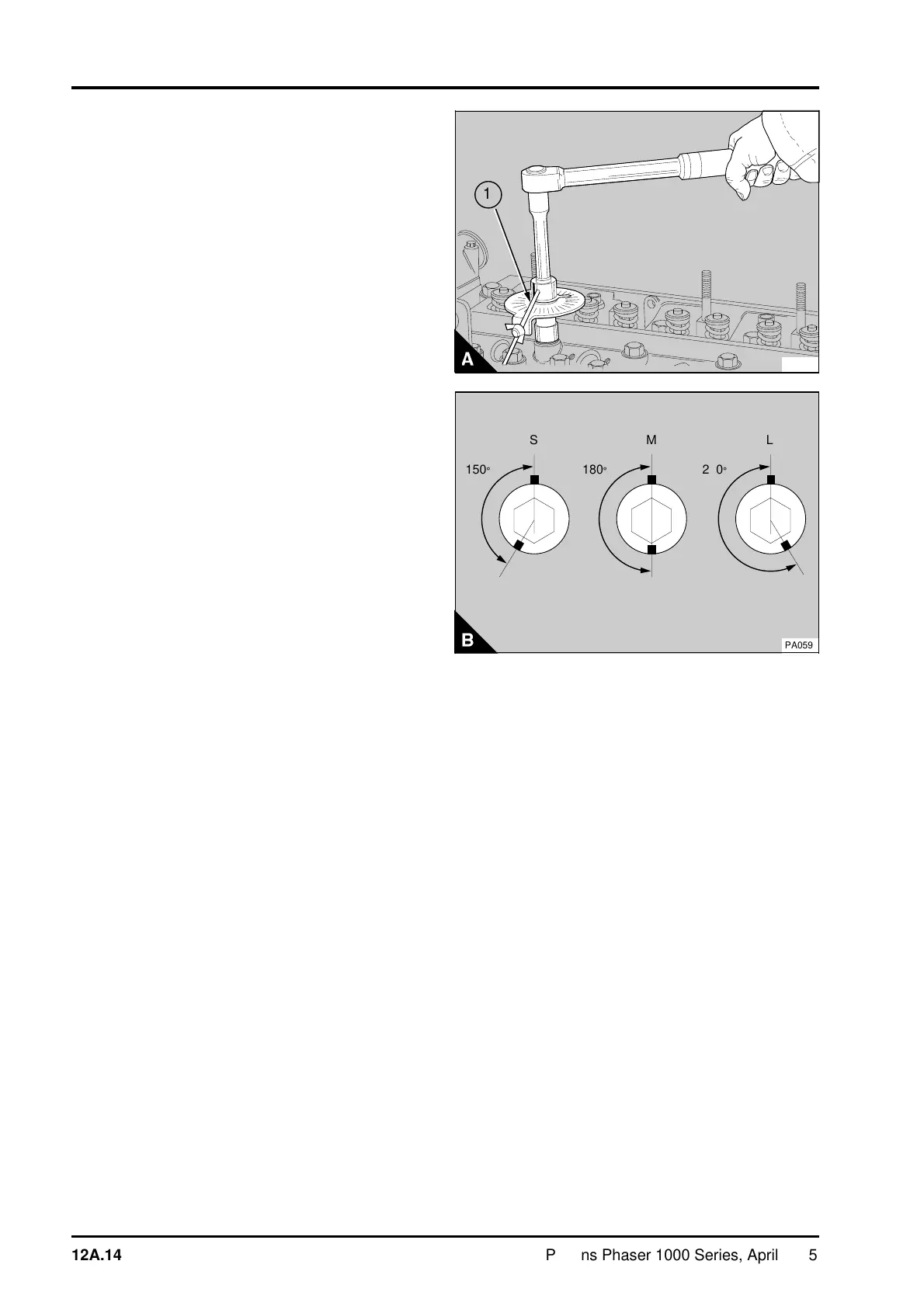

7 Tighten the setscrews, in the correct sequence,

a further part of a turn according to the length of

the setscrews, see (12A.12/A or B). Short

setscrews (S) must be turned a further 150°

(2.5 flats). Medium length setscrews (M) must be

turned a further 180° (3 flats). Long setscrews (L)

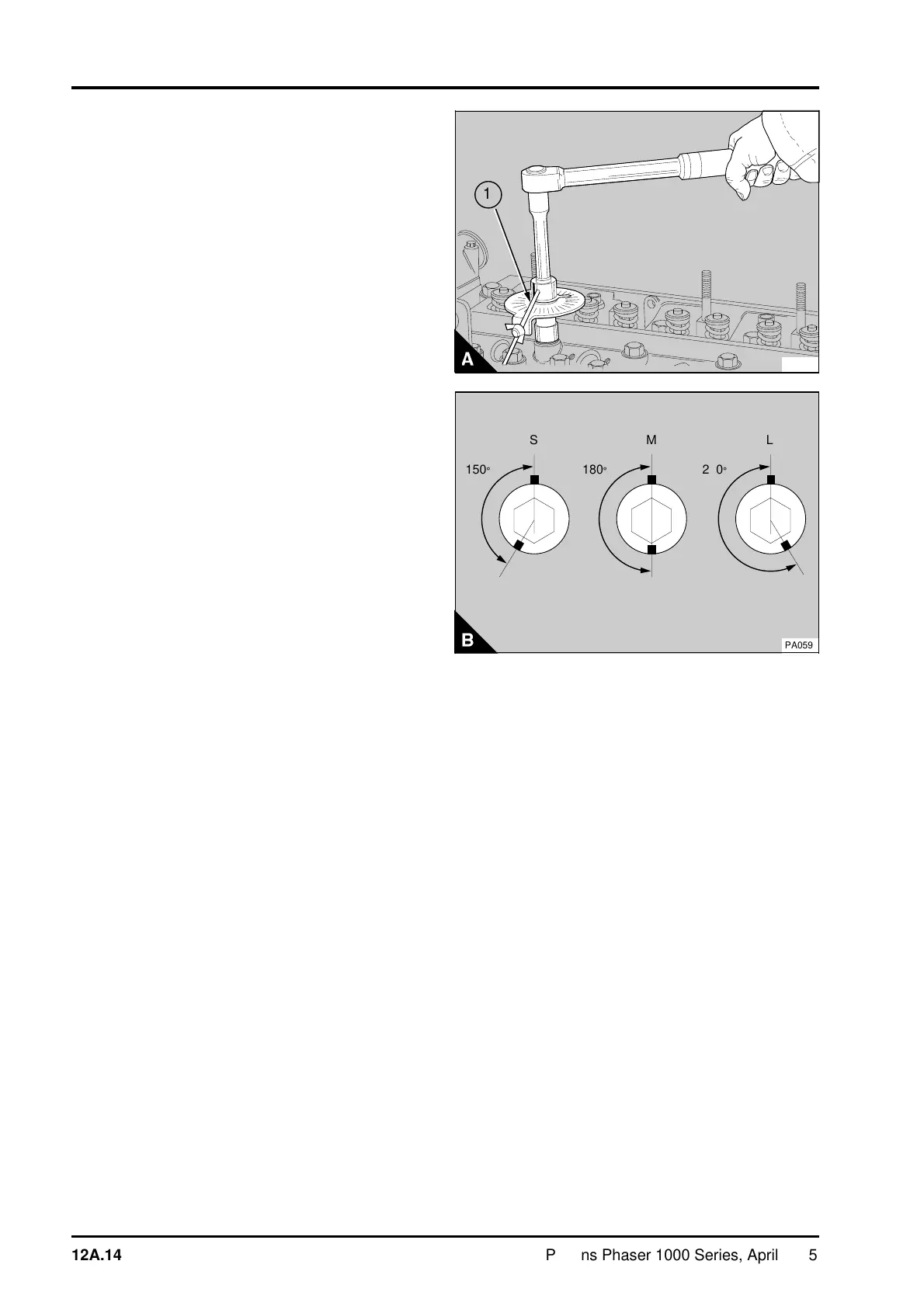

must be turned a further 210° (3.5 flats). A special

tool (A) can be used for this operation.

Fit the tool between the socket and the handle.

Position the stop (A1) against a suitable protrusion

on the cylinder head to prevent movement of the

degree dial in a clockwise direction. Rotate the

pointer to align with the relevant angle on the

degree dial for the length of setscrew. Tighten the

setscrew until the pointer on the tool is aligned with

the zero position on the degree dial.

If no tool is available, make a suitable mark on the

cylinder head in line with a corner of each setscrew

(B). Make another mark, at the correct angle

(counter-clockwise), on the edge of the flange of

each fastener according to the length of the

setscrew. Tighten each setscrew in the correct

sequence until the marks on the flange are next to,

and in line with, the marks on the cylinder head.

8 Put the push rods in position. Ensure that the

end of each push rod fits correctly in the tappet

socket.

9Fit the rocker assembly, operation 12A-01.

10Set the valve tip clearances, operation 12A-05.

11Fit the atomisers, operation 20A-02.

12 Fit the high-pressure fuel pipes; tighten the

connection nuts to 22 Nm (16 lbf ft) 2,2 kgf m.

Caution: Where access to the fuel injection pump

outlet unions is possible, ensure that a separate

spanner is used to prevent movement of the fuel

injection pump outlets when the connections of the

high pressure pipes are tightened.

13 Fit the fuel filter and the bracket. Fit the low-

pressure fuel pipes between the fuel injection pump

and the fuel filter.

14 Fit the coolant by-pass connection; tighten the

setscrews and hose clip.

15 If a compressor is fitted: Fit the coolant pipe

between the cylinder head and the compressor.

Then fit the pipe between the coolant by-pass and

compressor.

16 For turbocharged and some naturally aspirated

four cylinder engines: Fit the oil cooler, operation

21A-07A.

PA058

a

a

1

a

a

a

150°

a

S

a

a

a

a

180°

a

M

a

a

a

a

210°

L

PA059

12A.14 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...