13 PISTON AND CONNECTING ROD ASSEMBLIES

To fit

Special tools:

Piston replacer tool, PD.206

1 Ensure that the piston, the cylinder bore, the

crank pin and the big end of the connecting rod are

clean. Lubricate the piston and the cylinder liner

with clean engine lubricating oil.

2 Rotate the crankshaft until the relevant crank pin

is at its lowest position. Lubricate the crank pin with

clean engine lubricating oil.

3 Fit the upper half of the shell bearings to the

connecting rod. Ensure that the location tag is fitted

correctly in its recess. Lubricate the bearing with

clean engine lubricating oil.

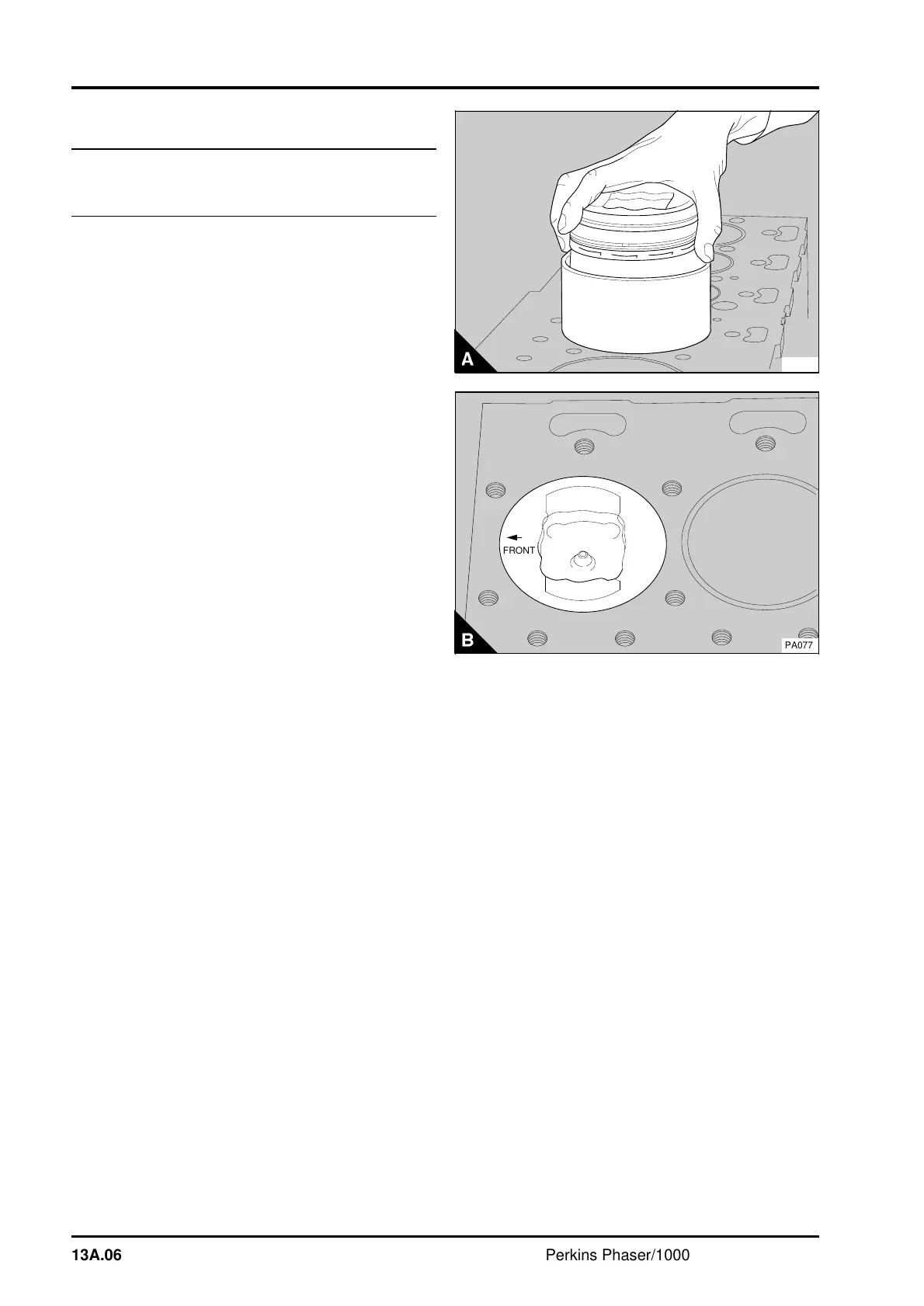

4 Put the piston replacer tool in position at the top

of the relevant cylinder. The tool has a tapered bore

to compress the piston rings when the piston and

connecting rod assembly is fitted. Ensure that the

smaller end of the tapered bore is towards the face

of the cylinder block.

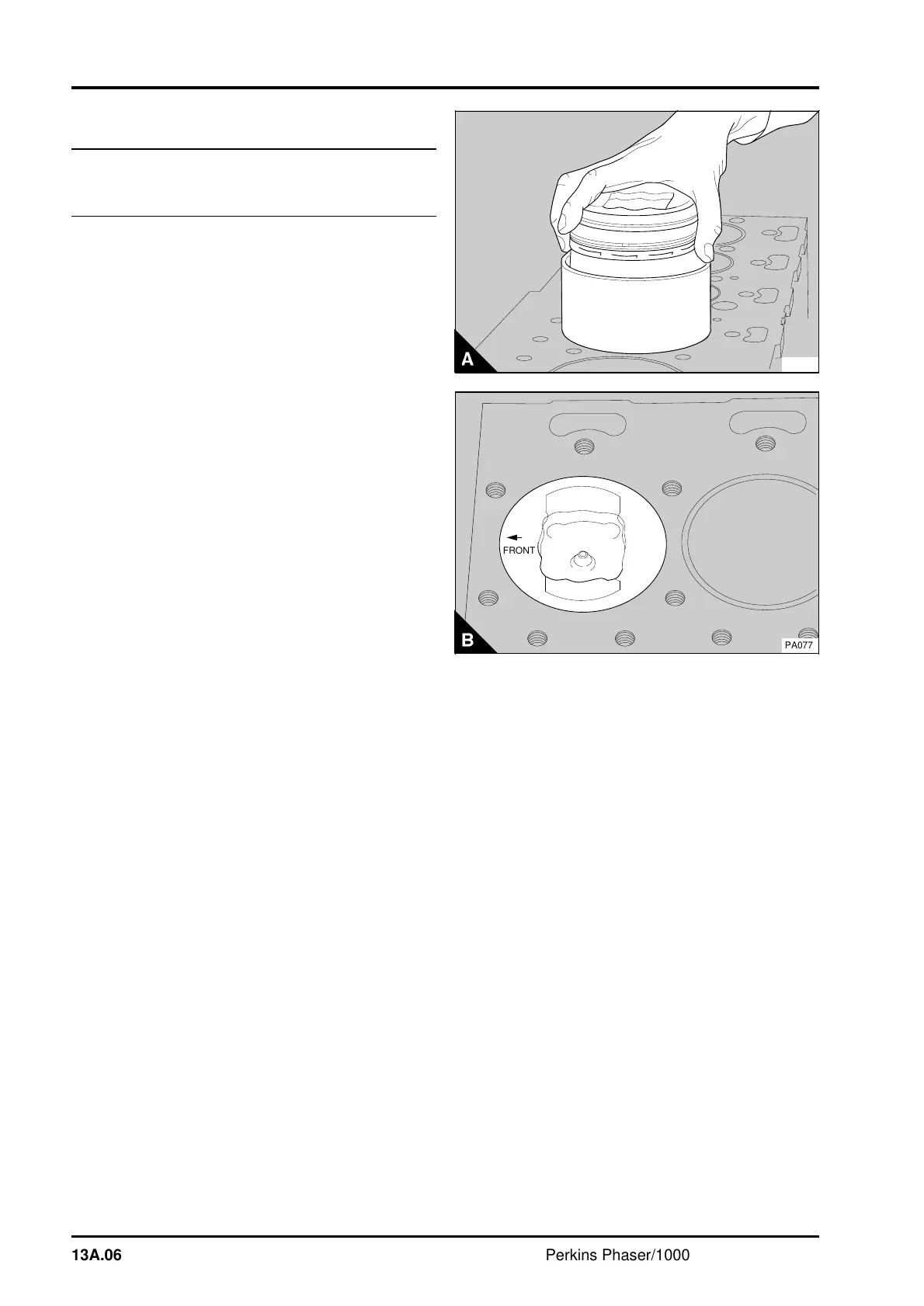

5 Put the piston ring gaps 120° apart. Pass the

connecting rod through the piston replacer tool and

allow the piston to enter the tool. The arrow or

"FRONT" mark on the top of the piston must be

towards the front of the engine. In this position the

combustion bowl in the top of the piston will be

towards the fuel injection pump side of the engine.

6 Push the piston and connecting rod assembly

through the piston replacer tool (A) and onto the

crank pin. If piston cooling jets are fitted, the piston

and connecting rod assembly must be rotated to

ensure that the connecting rod will not hit the piston

cooling jet as the assembly is fitted. When the

connecting rod has passed the piston cooling jet,

rotate the connecting rod until the arrow or

"FRONT" mark on top of the piston is towards the

front of the engine (B).

PA076

1

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

FRONT

PA077

13A.06 Perkins Phaser/1000 Series, April 1995

Loading...

Loading...