CRANKSHAFT ASSEMBLY 14

To fit

1 Clean the upper half of the shell bearing and

lubricate the bearing surface with clean engine

lubricating oil.

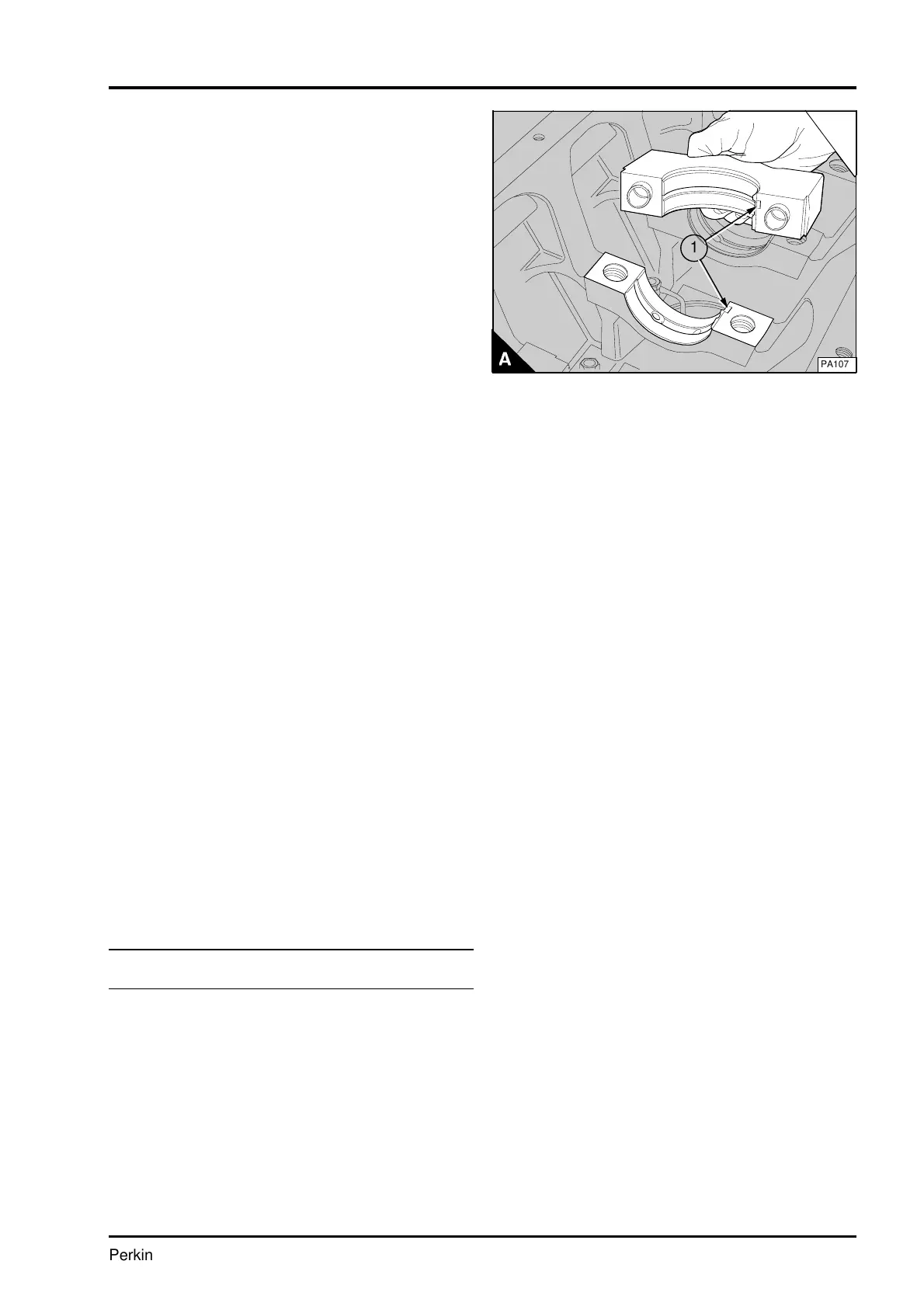

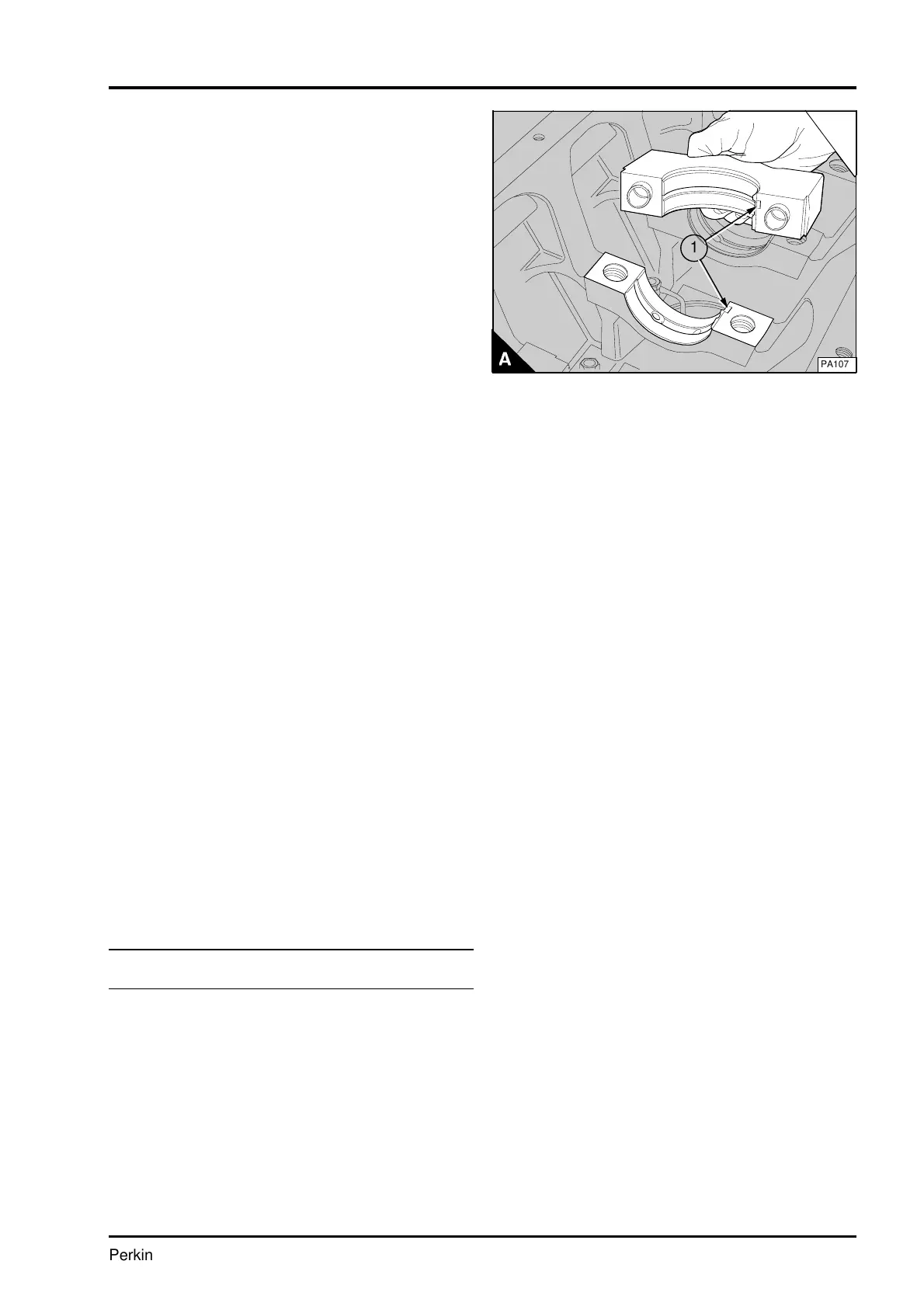

Caution: Only the upper half of the bearing has

lubrication holes and must be fitted to the side of

the cylinder block.

2 Fit the plain end of the upper half of the bearing

between the crankshaft journal and the side of the

bearing housing which has the recess for the

location tag. Slide the bearing into its housing until

the tag on the bearing is fitted correctly in its

recess in the housing.

3 Clean the lower half of the bearing and cap,

lubricate the bearing surface with clean engine

lubricating oil.

4 Fit the bearing into the cap with the tag of the

bearing fitted correctly in the recess in the cap.

5 Ensure that the location thimbles are fitted

correctly to the cap or to the cylinder block. Fit the

bearing cap with the location tags of both bearings

on the same side (A1).

6 Inspect the setscrews for damage and for

distortion and renew them if necessary. Lightly

lubricate the setscrew threads with clean engine

lubricating oil. Fit the setscrews and the washers

and tighten the setscrews gradually and evenly to

265 Nm (196 lbf ft) 27,0 kgf m for six cylinder

engines and 250 Nm (185 lb ft) 26,0 Kgf m for four

cylinder engines.

Note: Washers are not fitted between the

setscrews and the bearing caps on the latest

engines.

7 Ensure that the crankshaft turns freely. If the

thrust washers have been removed and fitted,

check the crankshaft end-float, operation 14A-03.

8 Fit all the components which were removed for

access to the main bearing cap.

9Fit the lubricating oil sump, operation 19A-03 and

fill it to the correct level with an approved

lubricating oil.

To inspect14A-07

Inspect the bearings for wear and for other damage.

If a bearing is worn or damaged, renew both half of

the shell bearings and check the condition of the

other bearings.

a

a

1

PA107

Perkins Phaser/1000 Series, April 1995 14A.17

Loading...

Loading...