PAGE 7

Nov 30/064D1

51-70-00

PIPER AIRCRAFT, INC.

PA-28-161, WARRIOR III

MAINTENANCE MANUAL

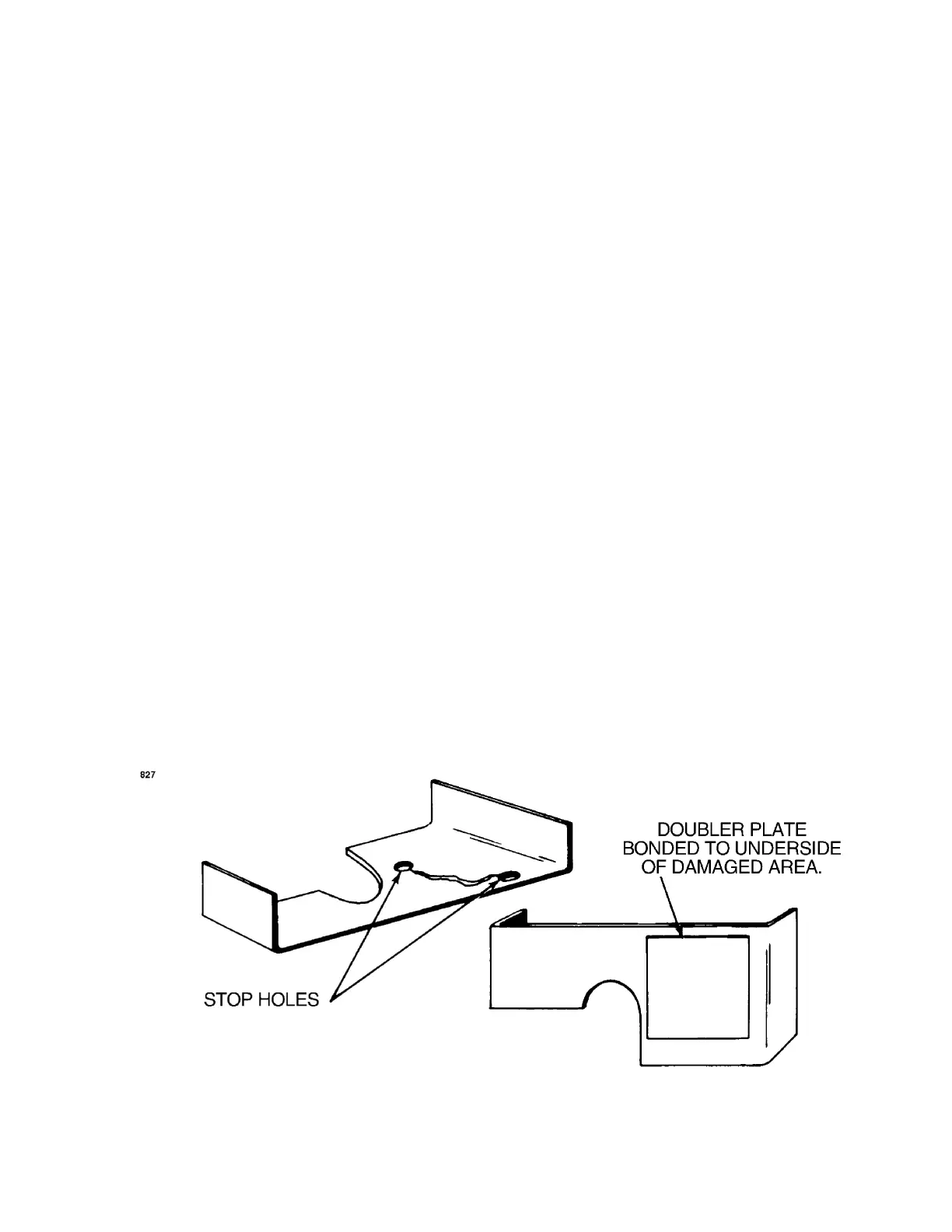

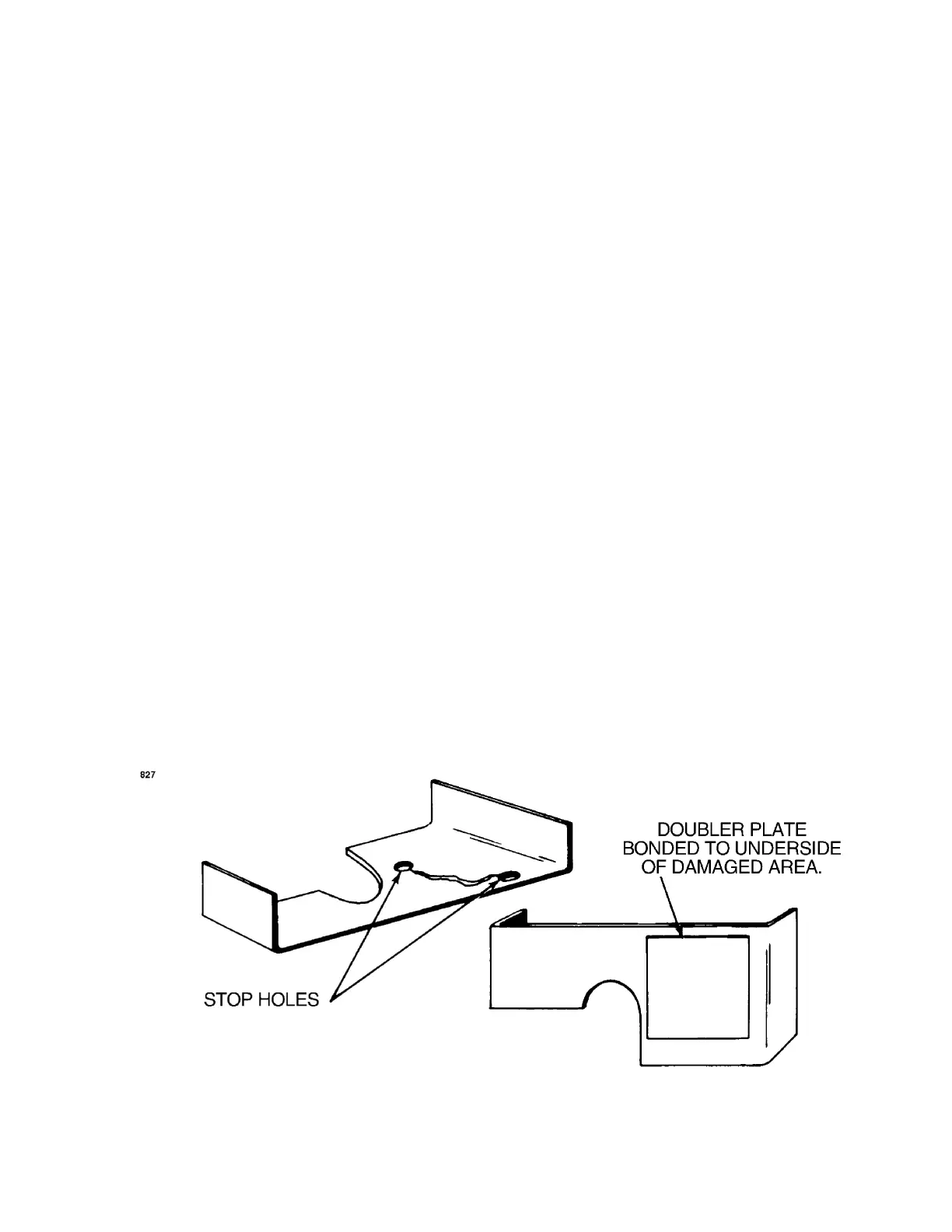

D. Cracks (See Figure 5.)

(1) Before repairing a crack in the thermoplastic part, first determine what caused the crack and

alleviate that condition to prevent it from recurring after the repair is made.

(2) Drill small stop holes at each end of the crack.

(3) If possible, a double plate should be bonded to the reverse side of the crack to provide extra

strength to the part.

(4) The crack should be “V” grooved and filled with repair material, such as solvent cement, hot

melt adhesive, epoxy patching compound or it should be hot air welded, whichever is

preferred.

(5) After the repair has cured, it may be sanded to match the surrounding finish.

E. Repairing Major Damage - Larger than 1 inch in diameter (See Figure 6.)

(1) If possible, a patch should be made of the same material, and cut slightly larger than the

section being repaired.

(2) When appearances are important, large holes, cracks, tears, etc, should be repaired by cutting

out the damaged area and replacing it with a piece of similar material.

(3) When cutting away the damaged area, under cut the perimeter and maintain a smooth edge.

The patch and/or plug should also have a smooth edge to ensure a good fit.

(4) Coat the patch with solvent adhesive and firmly attach it over the damaged area.

(5) Let the patch dry for approximately one hour before any additional work is performed.

(6) The hole, etc, is then filled with the repair material. A slight overfill of the repair material is

suggested to allow for sanding and finishing after the repair has cured. If patching compound is

used, the repair should be made in layers, not exceeding a 1/2 inch thickness at a time. This

will allow the compound to cure and ensure a good solid buildup of successive layers as

required.

Repairing of Cracks

Figure 5

Loading...

Loading...