PIPER AIRCRAFT, INC.

PA-28-161, WARRIOR III

MAINTENANCE MANUAL

PAGE 6

Nov 30/06

3E16

32-40-00

(d) Check the brake disc for grooves, scratches, pits or coning. Coning beyond 0.015 of an

inch in either direction would be cause for replacement. A single groove or isolated

grooves up to 0.030 of an inch deep would not necessitate replacement, but a grooving of

the entire surface would reduce lining life and should be replaced. If a powdery rust

appears on the disc, one or two taxi-braking applications should clear the rust up. Heavier

rust may require removal of the disc to wire brush it. Then finish sand with 220 grit

sandpaper. Should it be necessary to remove the wheel disc, refer to Wheels - Main

Wheels - Removal and Disassembly, above.

(e) Remove lining from backing plates by drilling or punching out the old rivets. Install a new

set using the proper rivets and a rivet set that will properly stake the lining and form a

correct flare of the rivet. (A rivet setting kit is available through Piper Distributors as Part

Number 754-165.)

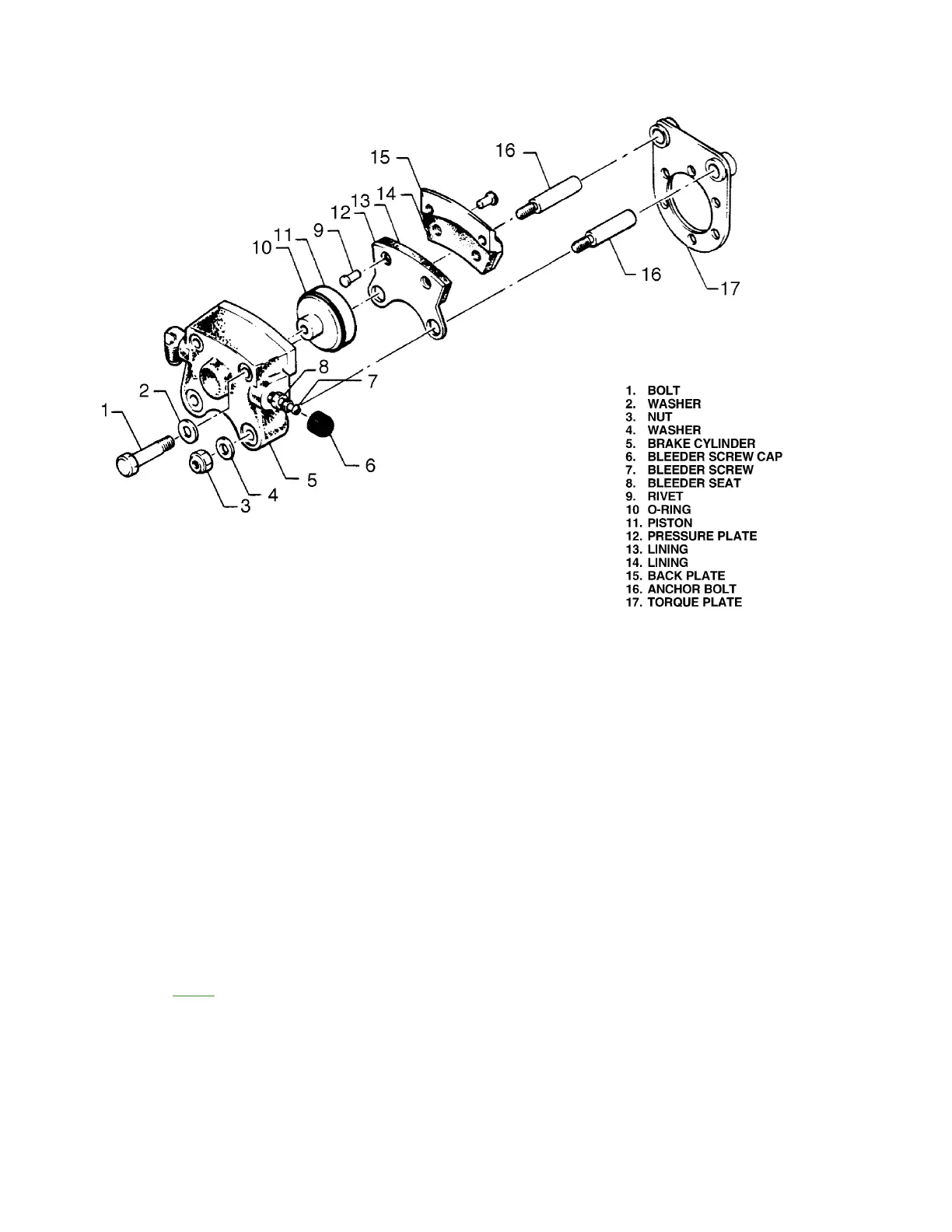

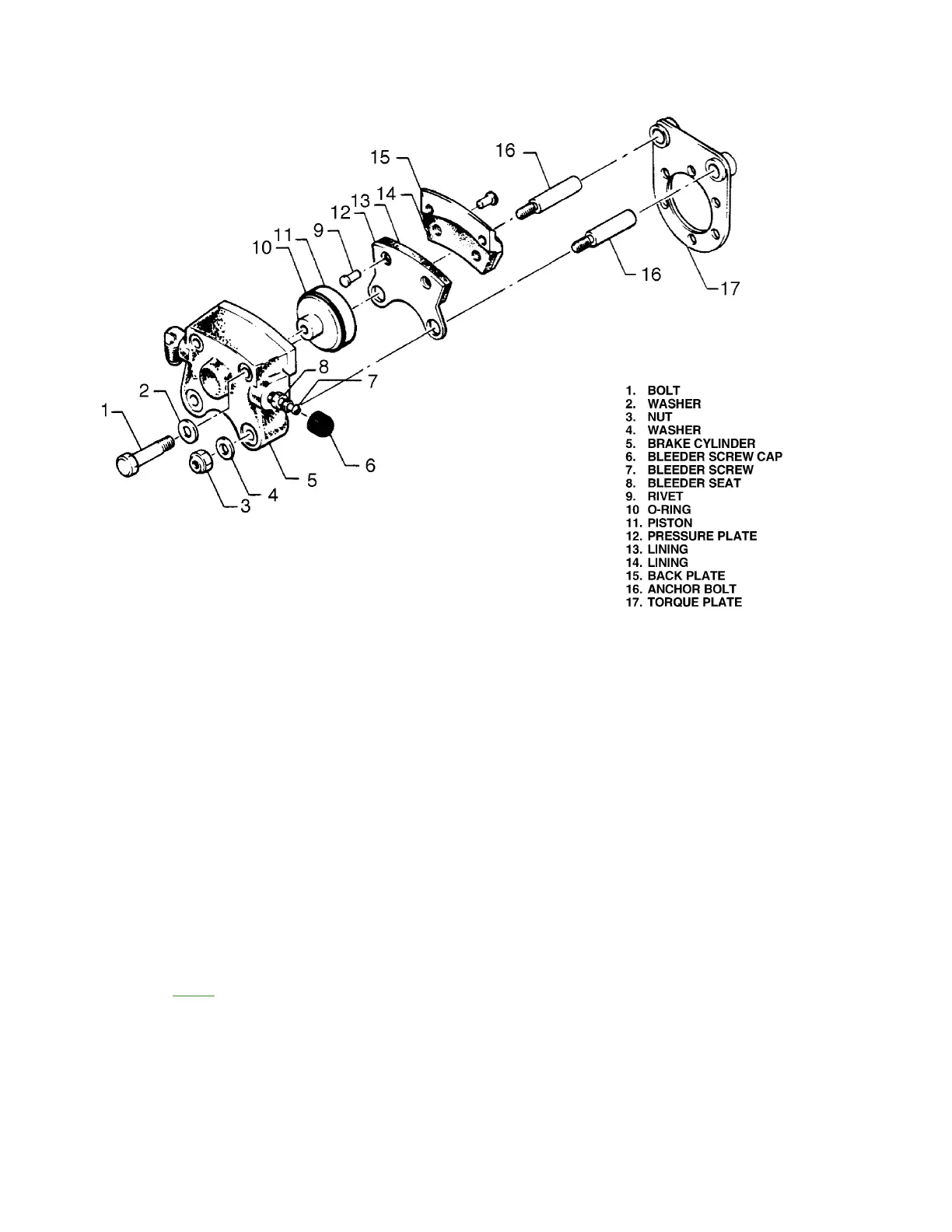

(4) Assembly and Installation (Refer to Figure 3.)

NOTE: If new linings are installed, they must be conditioned per Brake Adjustment,

Conditioning, and Lining Tolerances, above.

(a) Lubricate the piston O-ring with fluid MIL-H-5606 and install on piston. Slide the piston in

cylinder housing until flush with surface of housing.

(b) Slide the lining pressure plate onto the anchor bolts of the housing.

(c) Slide the cylinder housing assembly on the torque plate of the gear.

Wheel Brake Assembly (Typical)

Figure 3

Loading...

Loading...