PIPER AIRCRAFT, INC.

PA-28-161, WARRIOR III

MAINTENANCE MANUAL

PAGE 1

Nov 30/064G11

56-20-00

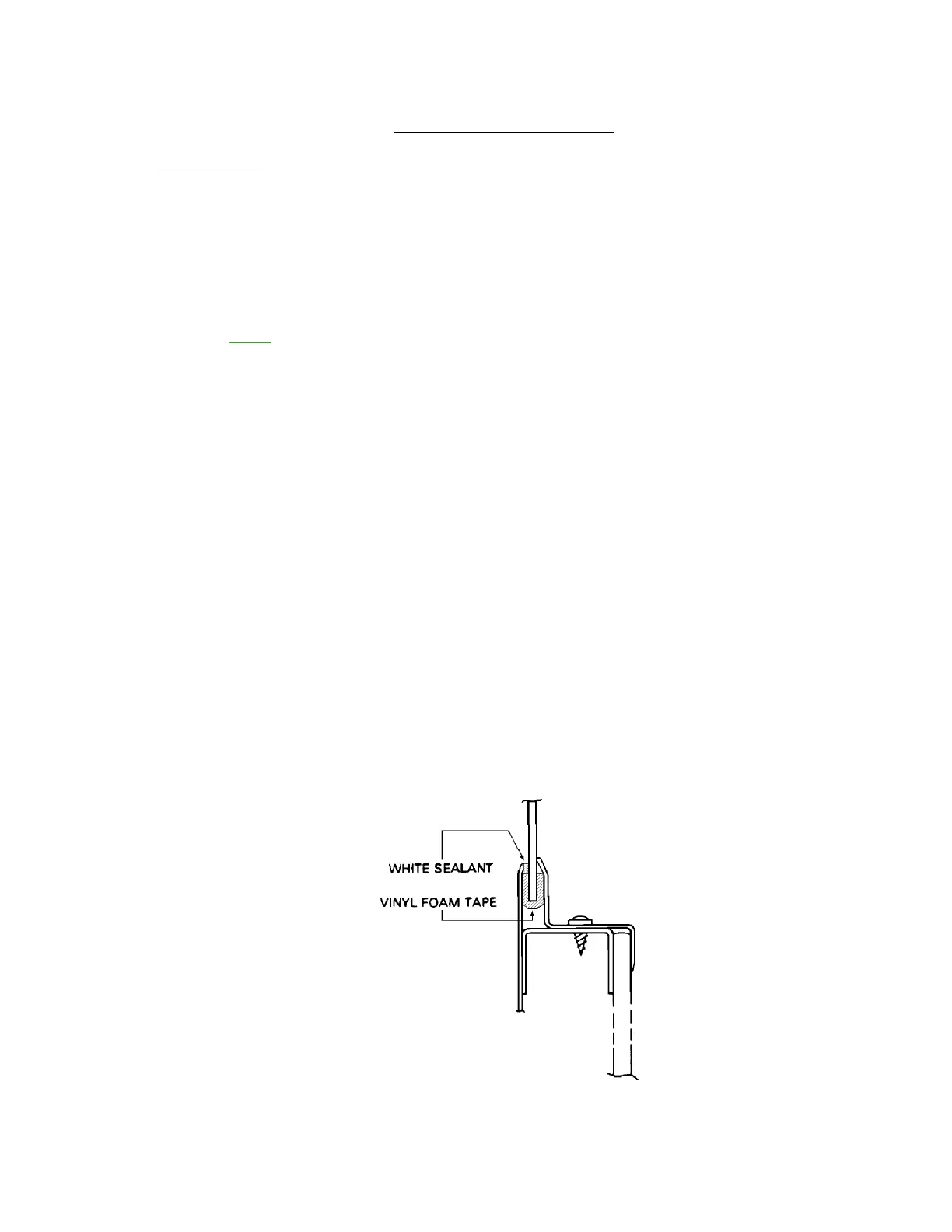

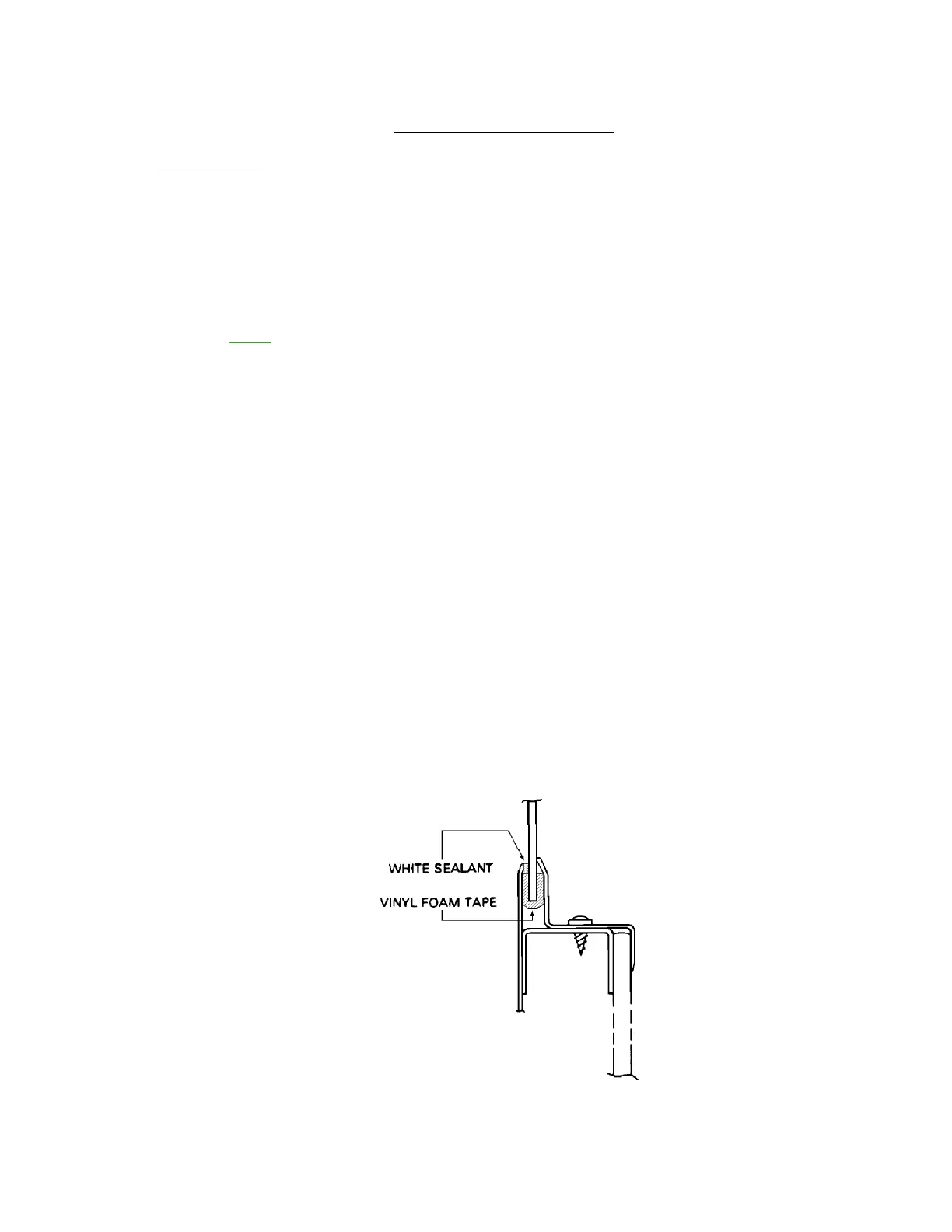

Side Window Installation

Figure 1

PASSENGER COMPAR

TMENT

Side Windows (Refer to Figure 1.)

These airplanes are equipped with single pane side windows.

A. Removal

(1) Remove retainer molding from around the top and sides of window by removing attachment

screws.

(2) Carefully slide window up and out of bottom retainer moulding (which is riveted in place) and

remove window from frame.

NOTE: A damaged window should be saved to provide a pattern for shaping the new

window.

(3) Remove excess tape and sealer from window, frame and retainer moldings.

B. Installation

(1) Match new window to old. If necessary, cut or grind the new window to the same dimensions.

(2) Apply 1/8 in. by 1 in. vinyl foam tape, Norton V510 or equivalent (i.e. - Tape - Vinyl Foam, Type 2;

91-10-00, Consumable Materials), around entire edge of window.

(3) Insert the window into the frame, install the retainer moldings and attachment screws, but do

not tighten. Take care not to damage or dislocate the vinyl foam tape.

(4) Apply polyurethane, urethane, acrylic, or polysulfide sealant (i.e. - Sealant - Window and

Airframe; 91-10-00, Consumable Materials), completely around the outer surface of the

window at all attachment flanges as indicated in Figure 1. Force the sealant between the

mating parts, which may be separated slightly using a soft wooden wedge or a tongue

depressor. Force sealant deep into the gap. Take care to avoid bending or scratching aluminum

or window surfaces. Joints should be completely filled, and blended smoothly with adjacent

surfaces after clean-up.

(5) Tighten attachment screws until vinyl foam tape is compressed approximately 25 percent.

(6) Remove excess sealant from window areas using rags, disposable wipers or plastic scrapers.

A tool made of acrylic sheet with a wedged end (.25 inch thick and 1.5 inch wide) can be

fabricated and used. Tirpolene solvent or Apperson solvent No. 120 may be used.to clean

polysulfide sealants.

Loading...

Loading...