PAGE 9

Nov 30/064D3

51-70-00

PIPER AIRCRAFT, INC.

PA-28-161, WARRIOR III

MAINTENANCE MANUAL

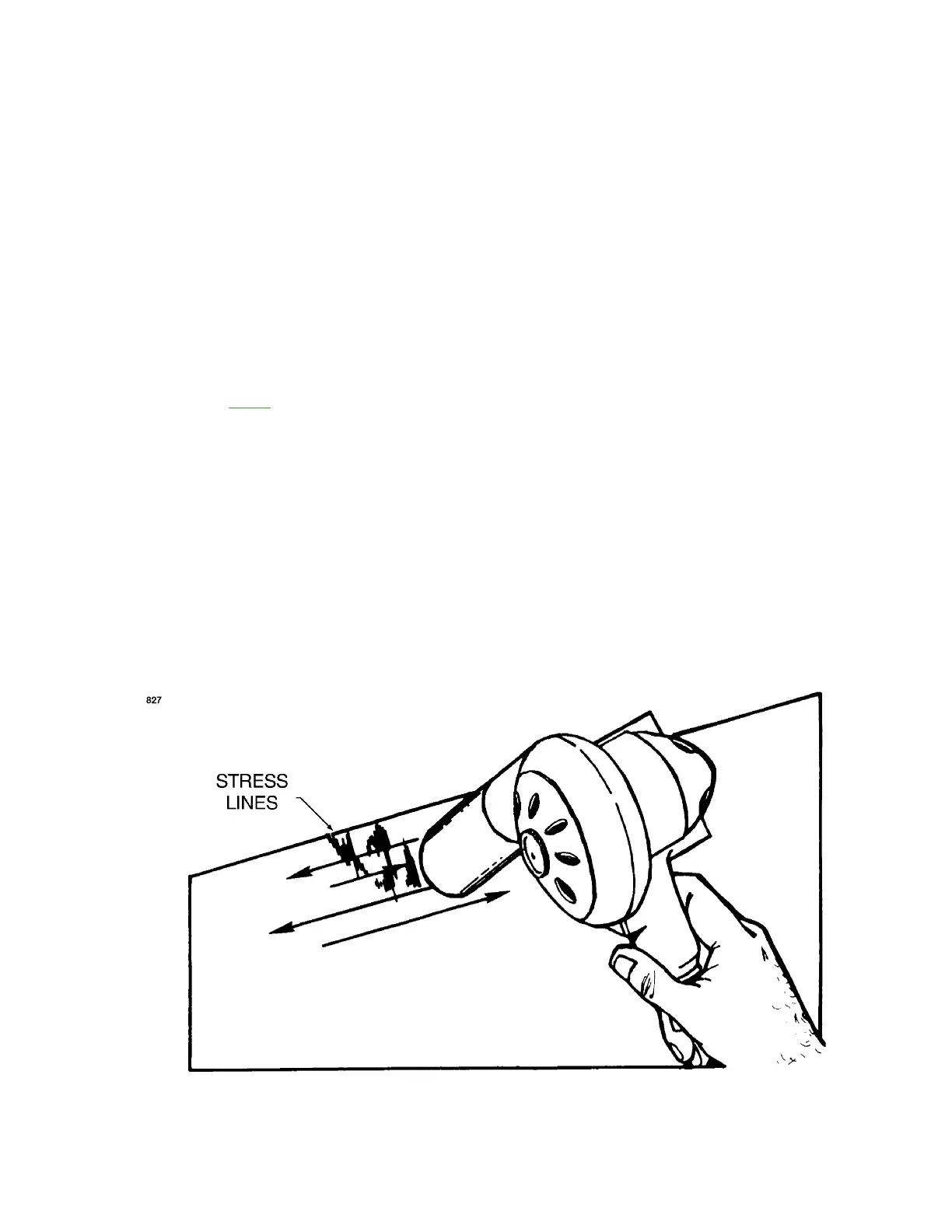

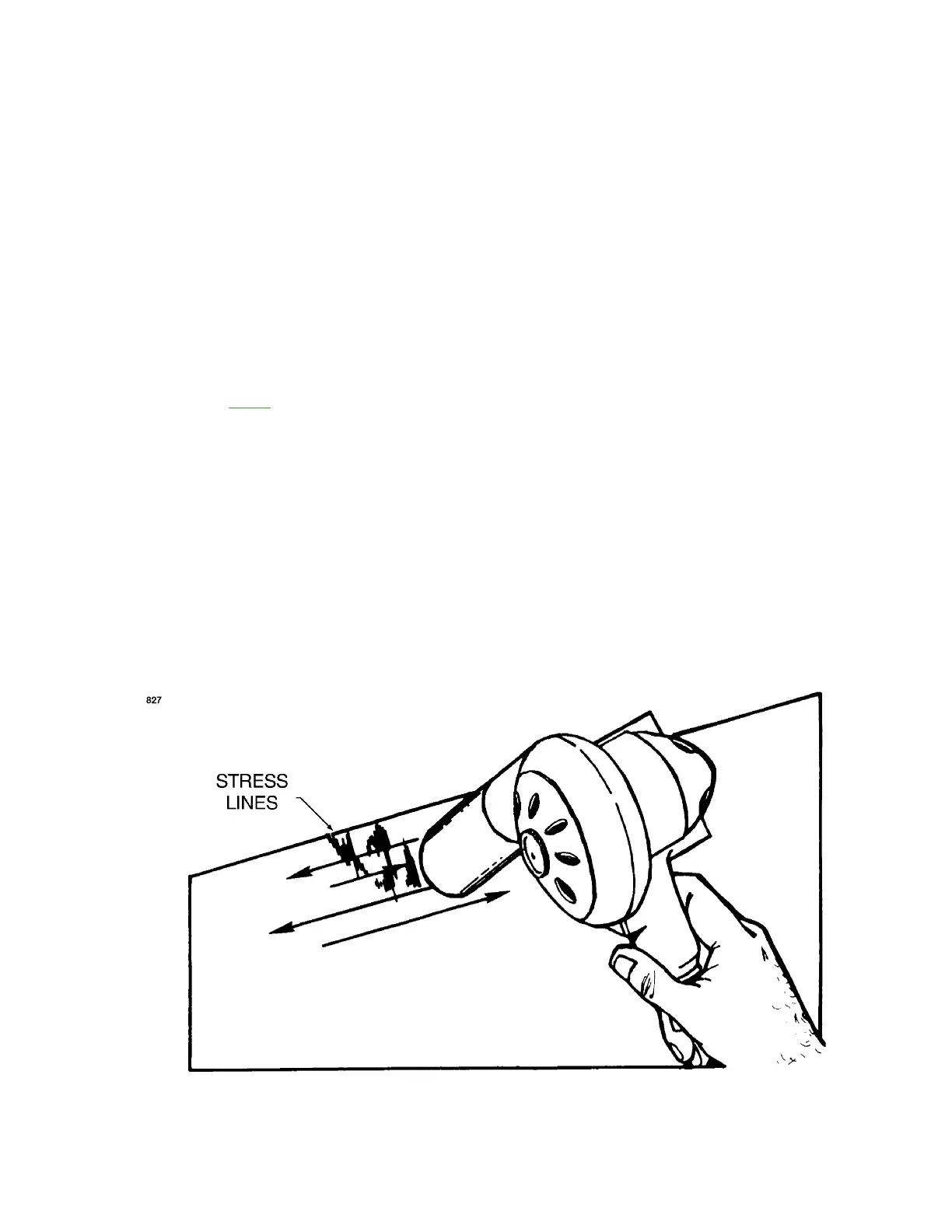

F. Stress Lines (See Figure 7.)

(1) Stress lines produce a whitened appearance in a localized area and generally emanate from

the severe bending or impacting of the material (see Figure 8).

(2) To restore the material to its original condition and color, use a hot air gun or similar heating

device and carefully apply heat to the affected area. Do not overheat the material.

G. Painting the Repair

(1) An important factor in obtaining a quality paint finish is the proper preparation of the repair and

surrounding area before applying any paint.

(2) It is recommended that parts be cleaned prior to painting with a commercial cleaner or a

solution made from one-fourth cup of detergent mixed with one gallon of water.

(3) The paint used for coating thermoplastic can be either lacquers or enamels, depending on

which is preferred by the repair facility or customer.

NOTE: It is extremely important that solvent formulations be considered when selecting a

paint, because not an lacquers or enamels can be used satisfactorily on

thermoplastic. Some solvents used in the paints can significantly affect and degrade

the plastic properties.

(4) Another important matter to consider is that hard, brittle coatings that are usually best for

abrasion resistance should not be used in areas which incur high stress, flexing or impact.

Such coating may crack, thus creating a weak area.

Repair of Stress Lines

Figure 7

Loading...

Loading...