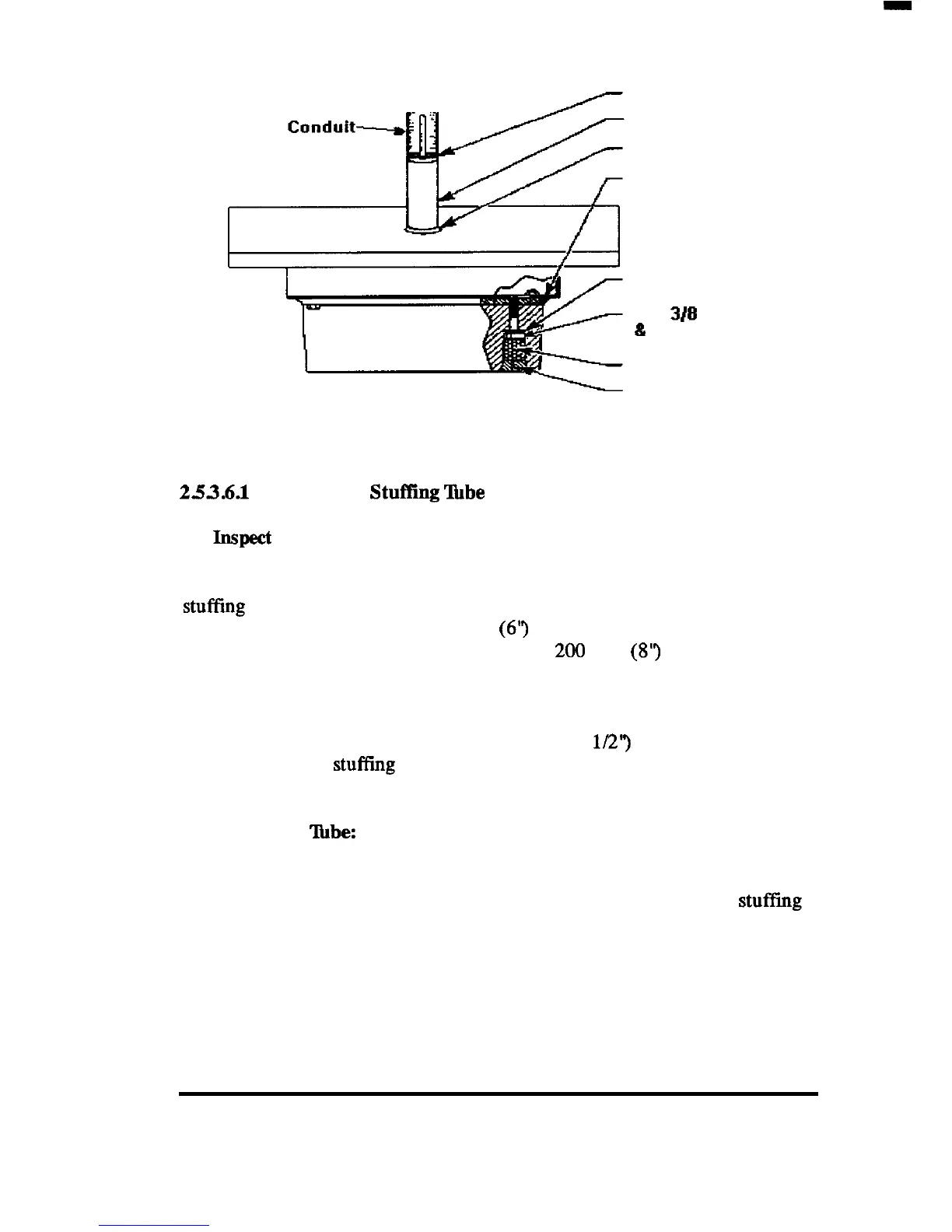

Weld all around

Stuffing Tube [Steel]

Weld all around

Sealant

Rubber washer

SST

3/8

Bolt

&

washer

Styrofoam Plug

Leveling Sealant

transducer will be installed and to allow clearance for the bolts used for

attaching the adapter plate.

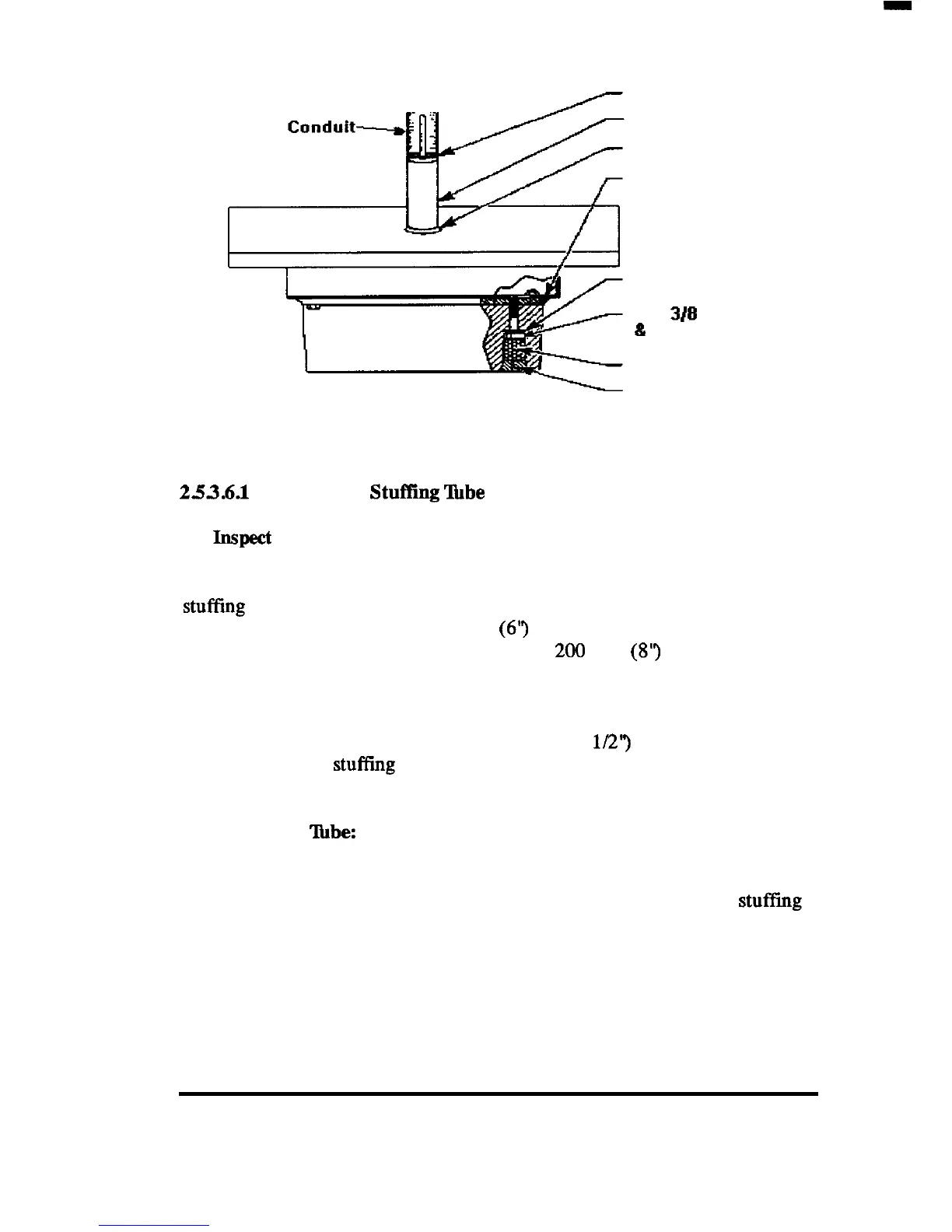

253.6.l

Installing the

Stuffing

‘Ihbe

1. Inspect

Location:

Prior to drilling or cutting from the outside of the hull, the interior of the

hull should be inspected to ensure that there is proper clearance for the

stufting

tube and that there are no cables or stakes to impede the cutting or

drilling. The stuffing tube is 150 mm

(6”)

in length and, depending on the

thickness of the hull, will require at least

200

mm

(8”)

of clearance to

facilitate routing of the cable.

2. Drill the Hole:

Drill or cut (with a cutting torch) a 38 mm (1

l/2”)

hole in the hull for

installation of the

stuffing

tube. A fire watch should be stationed inside the

hull.

3. Install the

‘Abbe:

Remove the packing nut, compression bushing, and washers from the

stuffing tube. These will be necessary at a later time to seal the stuffing

tube, after the transducer cable is fed up into the hull. Insert the

stufling

tube into the hull and weld the stuffing tube in place (See Figure).

INSTALLATION 32

Loading...

Loading...