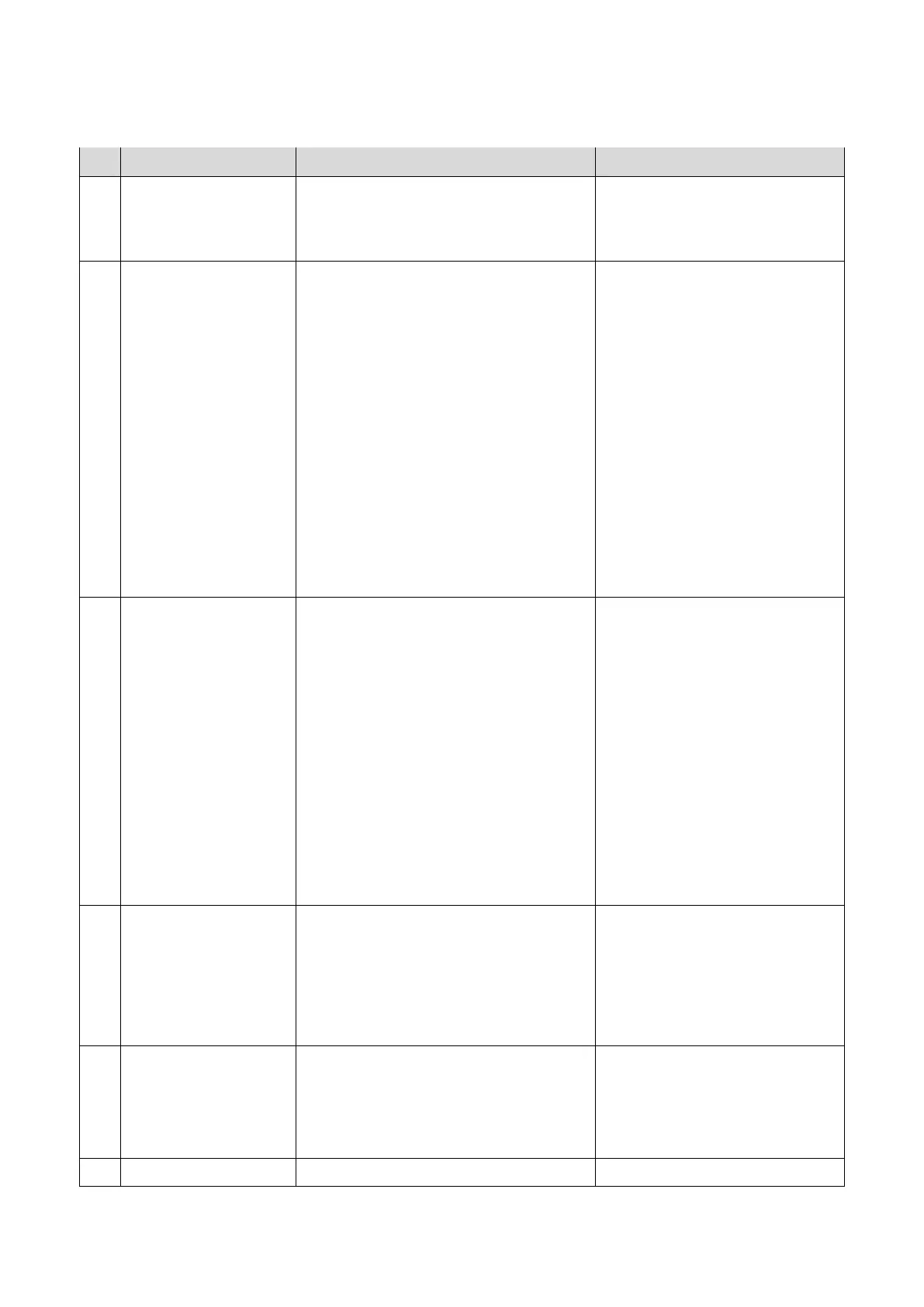

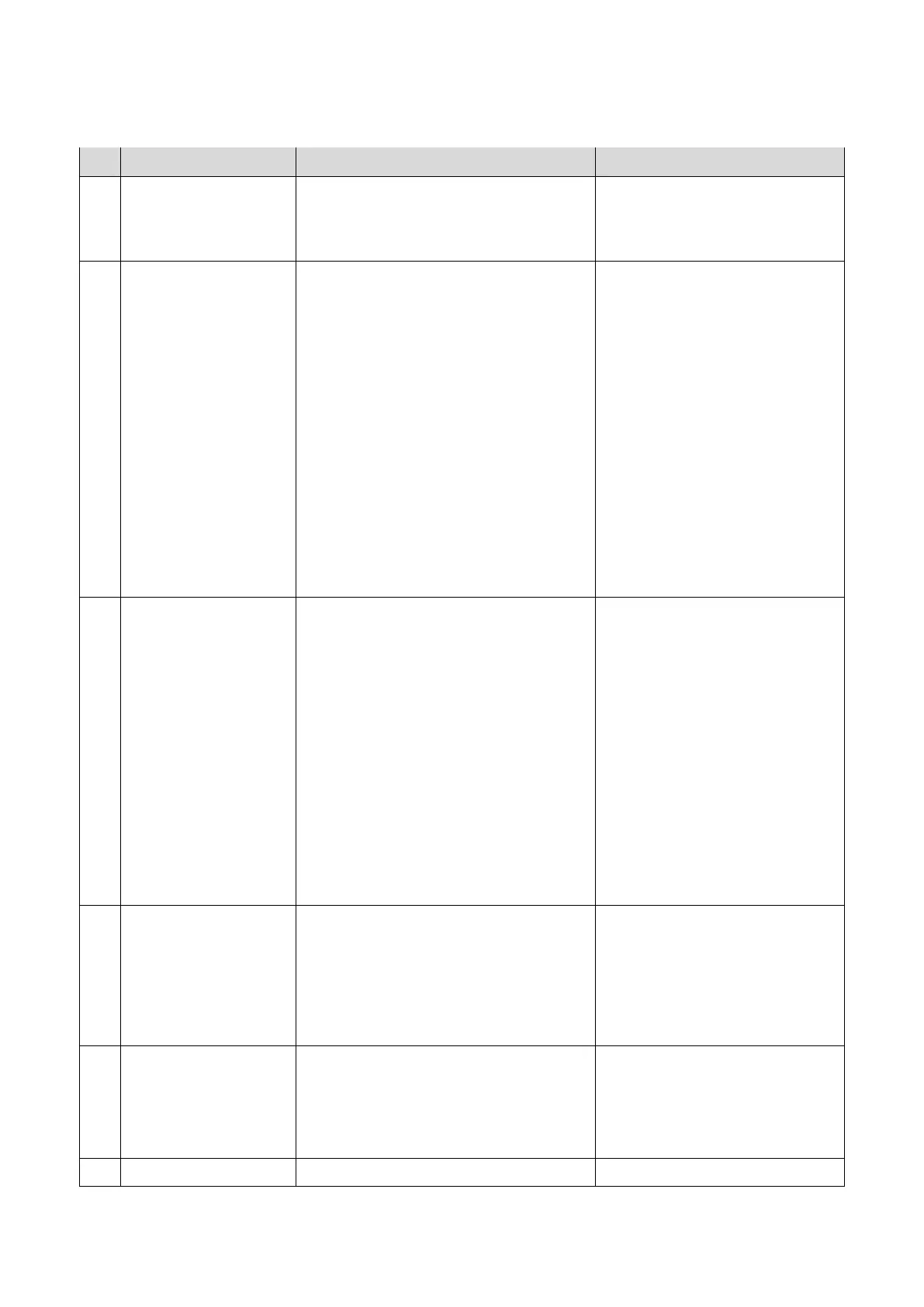

Process Control Error Conditions

500

SP3-012-001 to -010 (Process Control Execute Result)

No. Result Description Possible Causes/Action

11 Successfully completed Process control self-check successfully

completed.

Check the Vsg adjustment. See the

"Vsg Adjustment Result" following

this table.

41 Vt error Vt maximum or minimum error is

detected.

• Defective development unit

Vt maximum error and an image is

faint:

1. Replace the toner supply

pump unit.

Vt maximum error and an image is

O.K:

1. Replace the development unit.

2. Replace the BICU board.

Vt minimum error:

1. Replace the development unit.

2. Replace the BICU board.

53 ID sensor coefficient

(K5) detection error

Not enough data can be sampled.

• Solid image is not sufficient

density:

1. Retry the process control.

2. Replace the ID sensors.

3. Replace the BICU board.

• Solid image is O.K.

1. Replace the ID sensors.

2. Replace the BICU board.

• ID sensor is dirty:

1. Clean the ID sensors.

2. Retry the process control.

54 ID sensor coefficient

(K5) maximum/

minimum error

When the K5 is more than the value of

SP3-362-003 or less than the value of

SP3-362-004, the error 54 is displayed.

• ID sensor pattern density is

too high or low.

• ID sensor or shutter is

defective.

Same as 53

55 Gamma error:

Maximum

Gamma is out of range. 5.0 < Gamma

• ID sensor pattern density is

too high.

• Hardware defective.

Same as 53

56 Gamma error: Gamma is out of range.

• ID sensor pattern density is

Loading...

Loading...