Section 03 ENGINE

Sub-Section 03 (REMOVAL AND INSTALLATION)

03-03-6

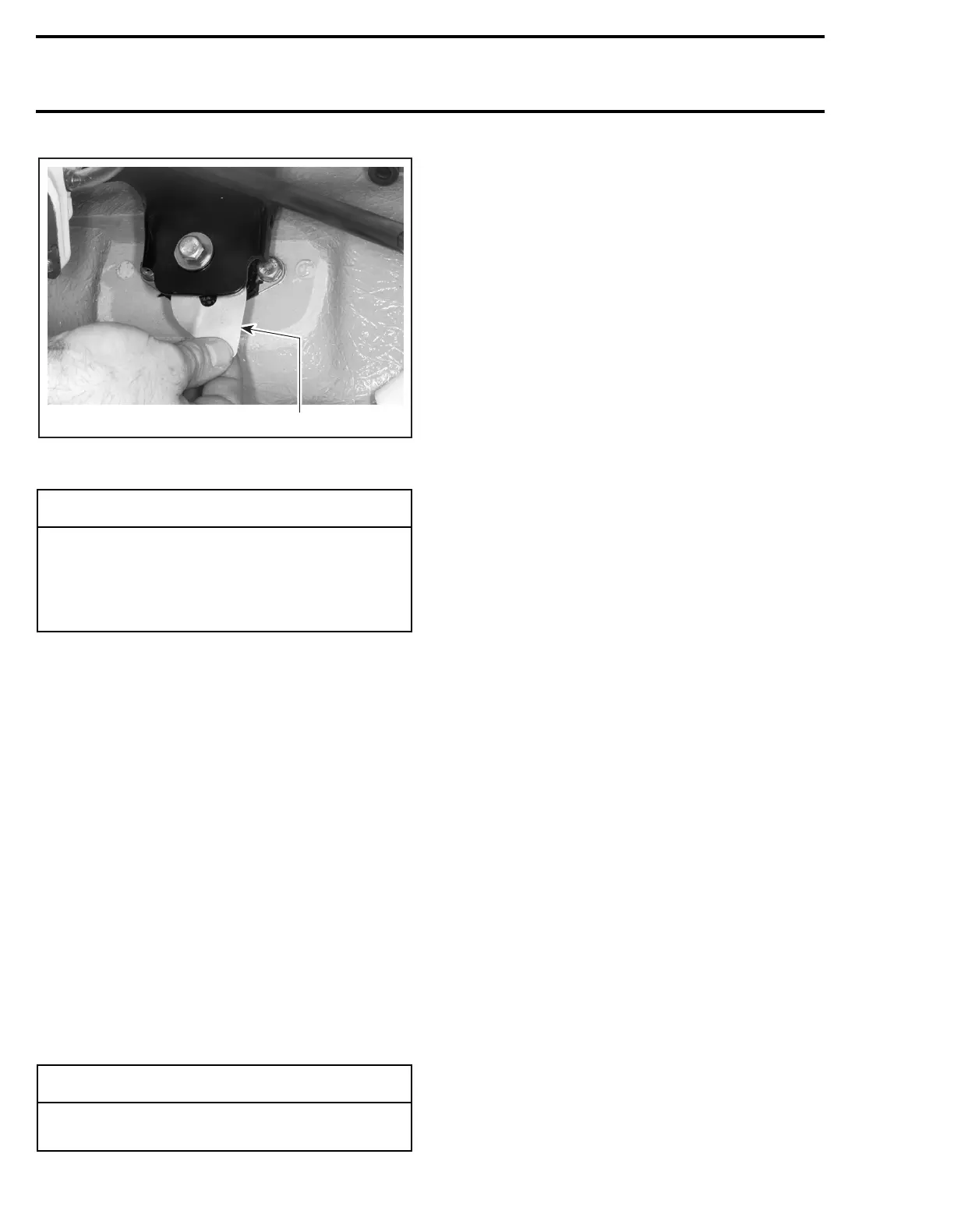

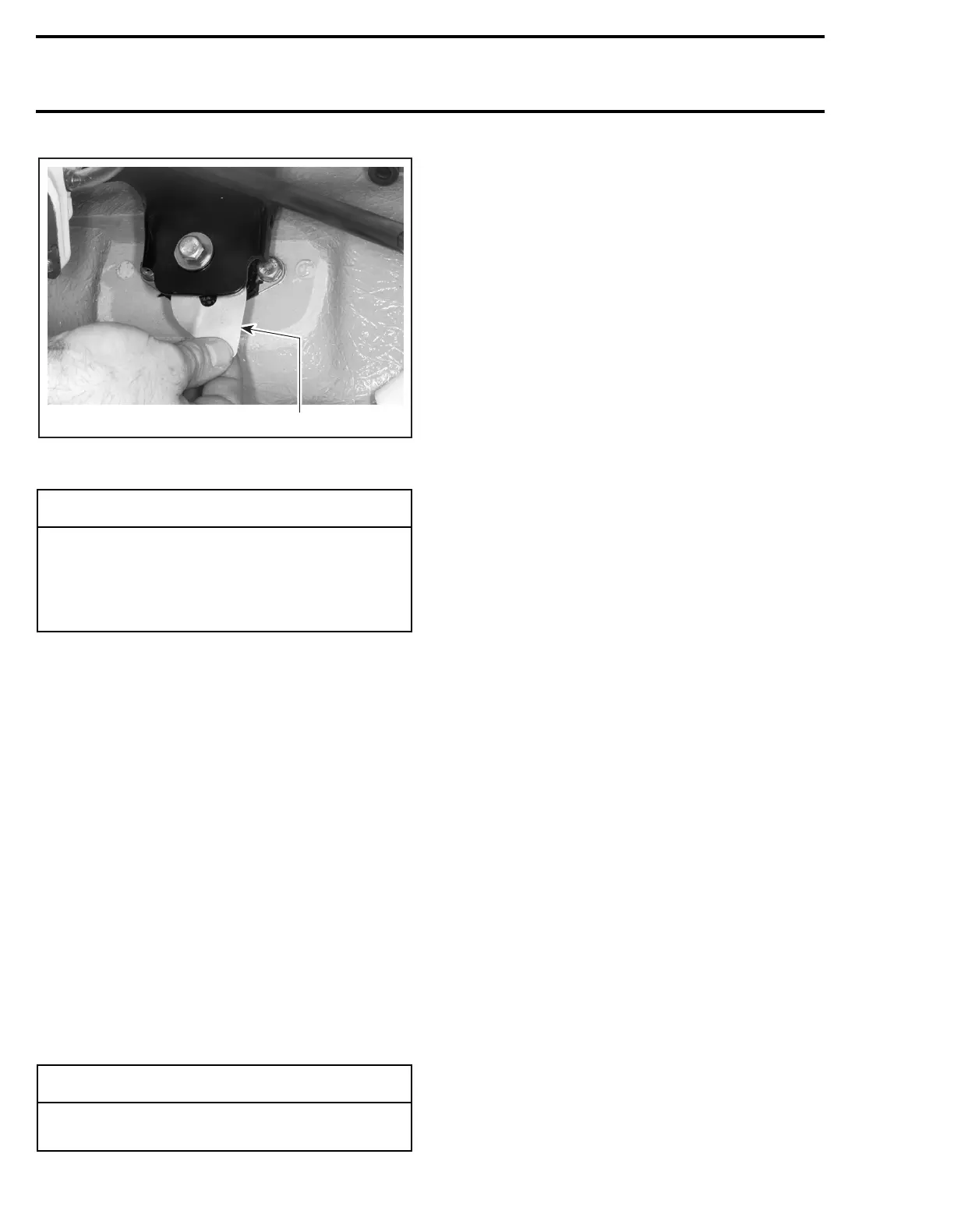

TYPICAL

1. Shim

Engine Support Screws

Apply Loctite 242 (blue) on screw threads.

Torque engine support screws to 25 N•m

(18 lbf•ft) when procedure is completed.

NOTE:

Whenever alignment tool is not utilized,

apply BOMBARDIER LUBE lubricant on its shaft

and inside the housing to eliminate possible corro-

sion.

Final Inspection

Check throttle cable condition and lubricate cable

with BOMBARDIER LUBE lubricant. After its in-

stallation, properly adjust and bleed oil injection

pump as specified in LUBRICATION SYSTEM

06-03.

Check hose condition and pressure test fuel sys-

tem, refer to FUEL SYSTEM 05-02.

Verify all electrical connections.

Run engine and ensure there is no leakage.

-

CAUTION

Whenever shims are used to correct align-

ment, never install more than 6 mm

(0.240 in) shim thickness. If alignment can-

not be obtained verify for engine support

bending.

-

CAUTION

If watercraft is out of water, engine must be

cooled using the flush kit.

F00D0CA

1

Loading...

Loading...