SEEDMASTER 2023

15

Wing-Down pressure may need to be increased if the wings start to float and not contour correctly while

in the seeding position or if a positive Wing-Up pressure is detected.

Wing-Down pressure may need to be decreased if the wings become too rigid while in the

seeding position.

RAVEN (METER) SUPPLY PRESSURE: 2000 psi

LIFT KIT: 200 psi

FAST WING PRESSURE: 1500 psi

SAFETY SHIFT VALVE: The safety shift valve will shut the hydraulic flow off to the block if back

pressure reaches 240 psi on tank line to prevent system damage.

PRESSURE SETTING PROCEDURES

Setting Wing-Down Procedure (WING-DOWN PRESSURE)

The Wing-Down pressure is the amount of hydraulic pressure being applied to the inner and outer wing

circuits; the oil supply is supplied from the system pressure. The Wing-Down Pressure is required so the

wings will contour while travelling through the field. SeedMaster requires Net Wing-Down Pressure. To

determine your net value, subtract your wing-up pressure from your current wing-down pressure (

ie.

380

PSI wing-down – 200 PSI wing-up = 180 PSI net wing-down).

- To adjust the WING-DOWN PRESSURE, loosen the jam nut on the cartridge in port WD on the

main block. Turn the cartridge in to increase the pressure, and out to decrease the pressure.

When the desired pressure is set, re-tighten the jam nut.

Setting Wing Unfold Procedure (FAST WING PRESSURE)

The wing unfold pressure is the amount of hydraulic pressure being applied to the inner and outer wing

circuits while the tool bar is unfolding. This is also known as the Fast Wing Pressure. If the wings are not

unfolding the pressure will need to be increased. The oil supply is supplied from the system pressure.

- To adjust the FAST WING PRESSURE, loosen the jam nut on the cartridge in port FW PRESS

on the main block. Turn the cartridge in to increase the pressure and out to decrease the

pressure. When the desired pressure is set, re-tighten the jam nut.

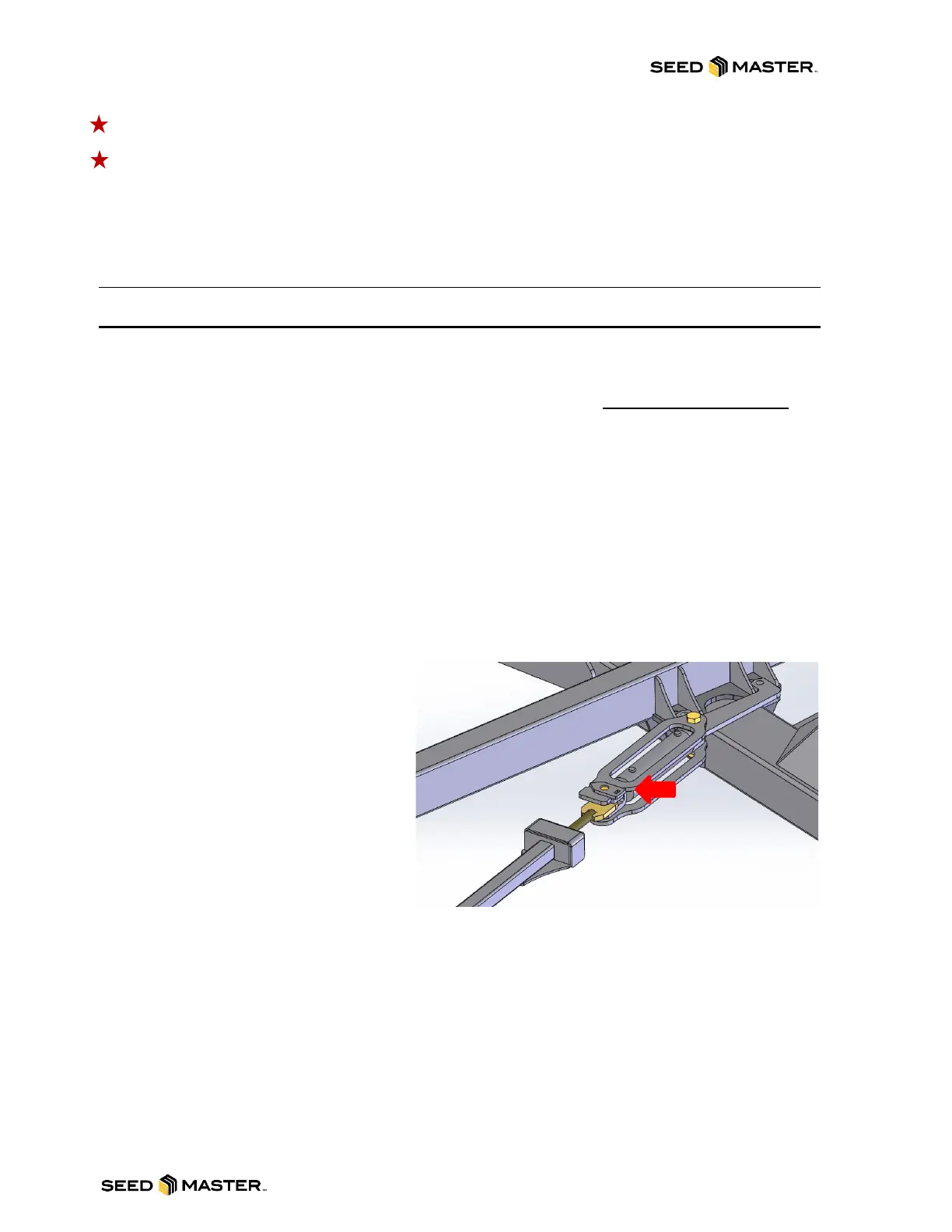

Active Wing Brace Check

The Active Wing Brace supports the wing

sections of the frame. While in the field, a

hydraulic cylinder pulls the rear of the wing

section forward counteracting draft while

seeding. The hydraulic pressure comes

from the opener cylinder hydraulic circuit.

The higher the pressure is set to the active

wing brace circuit, the more it will pull the

rear wing square. When the packing

pressure is increased, so is the amount of

pull on the brace to a set maximum.

- Adjusting the wing brace: Start

by unfolding the SM drill and

activating the system pressure.

Next, pressure the openers down with the opener pressure switch and adjust the shank down

hydraulic pressure to 1000psi, activating the active wing braces. After the system has been

completely pressurized, inspect each wing brace cylinder indicator. They should be fully

retracted against the plate limiter. If not, please adjust the length of the active wing brace using

the threaded link. The braces should be periodically checked to ensure proper adjustment. This

will ensure your frame integrity remains true and helps increase the longevity of your machine.

Meter Drive Pressure Setting Procedure (RAVEN METER SUPPLY PRESSURE)

The Meter Drive Pressure is the amount of hydraulic pressure allowed to the hydraulic metering drives.

The torque to the metering drives increases as the pressure increases. Do not exceed 2200 psi. The oil

supply for RAVEN METER SUPPLY PRESSURE is supplied from the system pressure.

- To adjust the RAVEN METER SUPPLY PRESSURE, loosen the jam nut on the cartridge in port

RAVEN on the main block. Turn the cartridge in to increase the pressure and out to decrease

the pressure. When the desired pressure is set, re-tighten the jam nut.

Loading...

Loading...