SEEDMASTER 2023

35

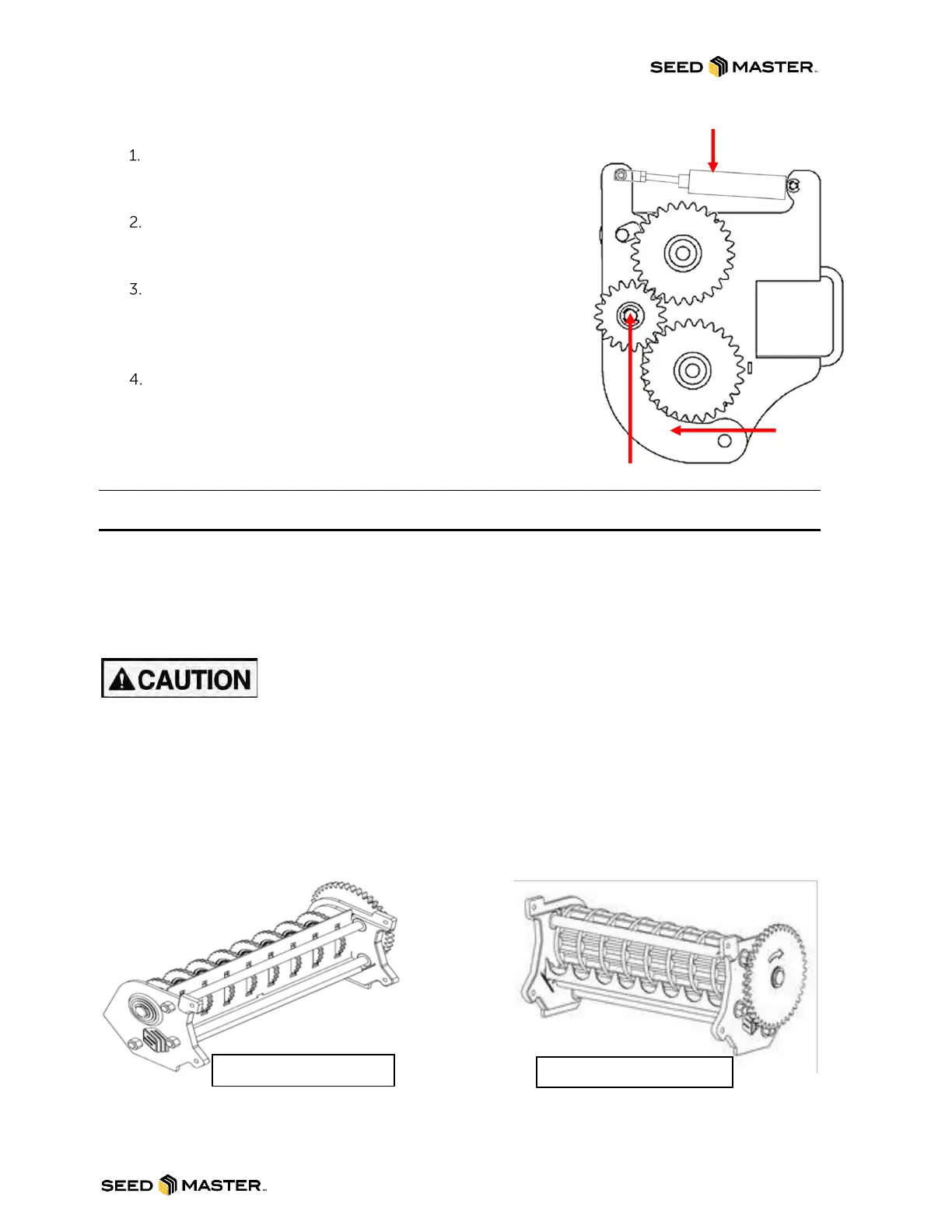

Zone Command Check

Manually extend air cylinder rod so that engaging gear is

disengaged. Ensure gear turns freely, and both the air

cylinder and pivot arm pivot freely.

The pivot arm is designed with limits for engaging and

disengaging. This will allow the gear to engage smoothly and

prevent binding and excessive wear.

Test the Zone Command by pulling on the air cylinder rod

and letting go of the rod. The cylinder should retract on its

own to the seeding position. If it has tight pivot point, it may

cause the pivot arm to not return to the seeding position.

Ensure that all quick keeper pins are installed into the roller

cartridges and seed guide tube, this will keep the meter

rollers retained and in the proper drive position.

UPII CALIBRATION PROCEDURE PRE-SETUP

Check the metering rollers. Worn, encrusted, or dirty rollers will not meter accurately. Ensure that the

metering ledge is free of buildup as product application rate can be affected by the gap between the

metering rollers and metering ledge.

Note: It is crucial that all metering rollers are installed fully, ensuring that all retaining quick pins are

placed into all pin locations.

Hoppers must contain material. Use Zone Command controls to

dispense product from the desired metering section. Be prepared to

catch the material from one metering section in a container so it can be weighed at the end of

the calibration.

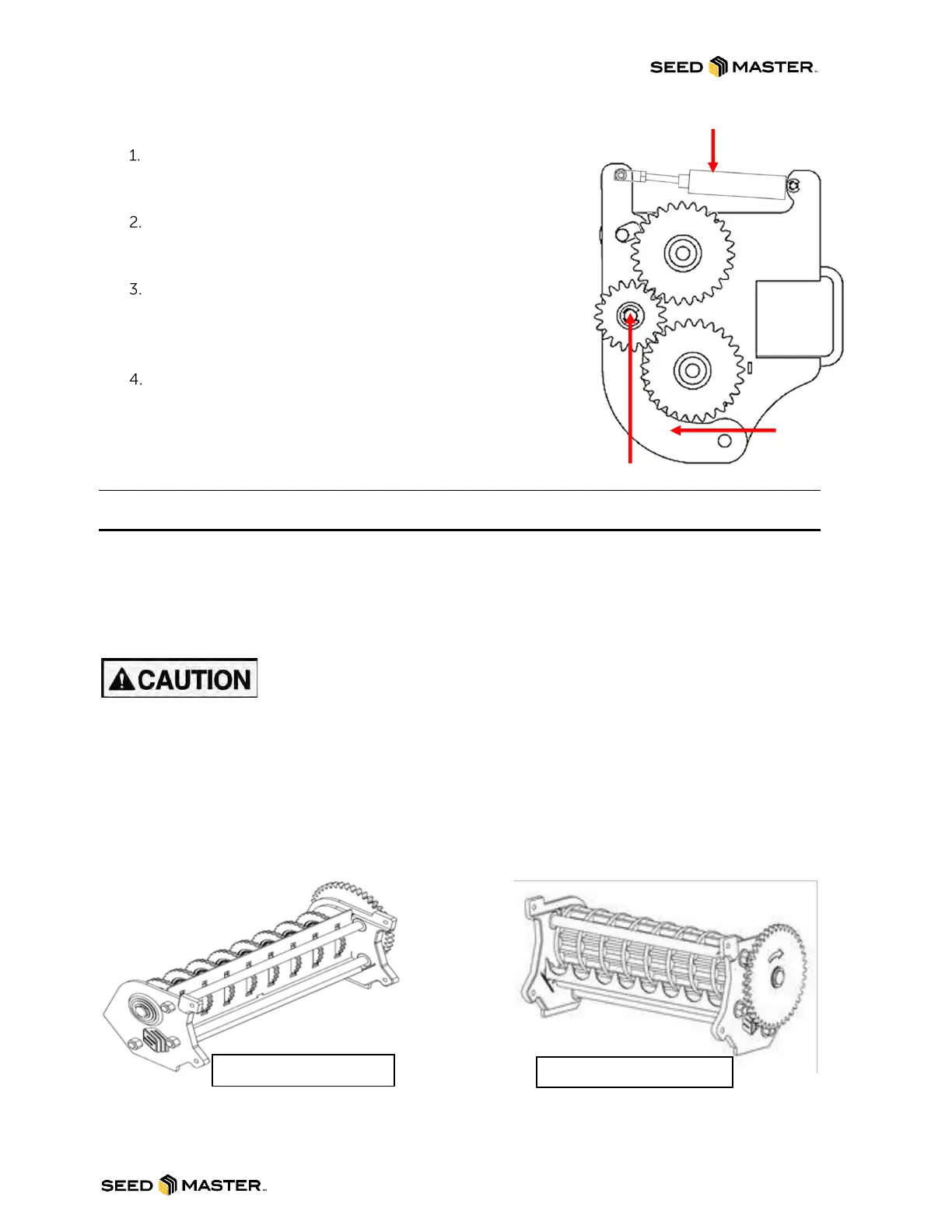

ULTRAPRO II METER ROLLERS:

The UltraPro II Canola Roller can be used to meter Canola, Mustard, Granular Inoculant,

and other fine products.

The UltraPro II Standard Roller can be used to meter Cereals, Lentils, Peas, Beans, and

other coarse products.

Loading...

Loading...