82

x:origin detector and rotation option

0:Running in CCW rotation and LSP is as a trigger

1:Running in CW rotation and LSN is as a trigger

2:Running in CCW rotation and ORGP↑ is as a trigger

3:Running in CW rotation and ORGP↑ is as a trigger

4:Running in CCW rotation and Encoder Z pulse as a trigger

5:Running in CW rotation and Encoder Z pulse as a trigger

6:Running in CCW rotation and ORGP↓ is as a trigger

7:Running in CW rotation and ORGP↓ is as a trigger

8:Current position as a origin

y:origin attained shortcut moving option

0:motor turns back to last Z pulse to attain

1:motor goes ahead to next Z pulse to attain

2:origin recognized right away

z:origin recognized completion option

0:motor decelerates to stop then return to the mechanism origin

1:motor decelerates to stop

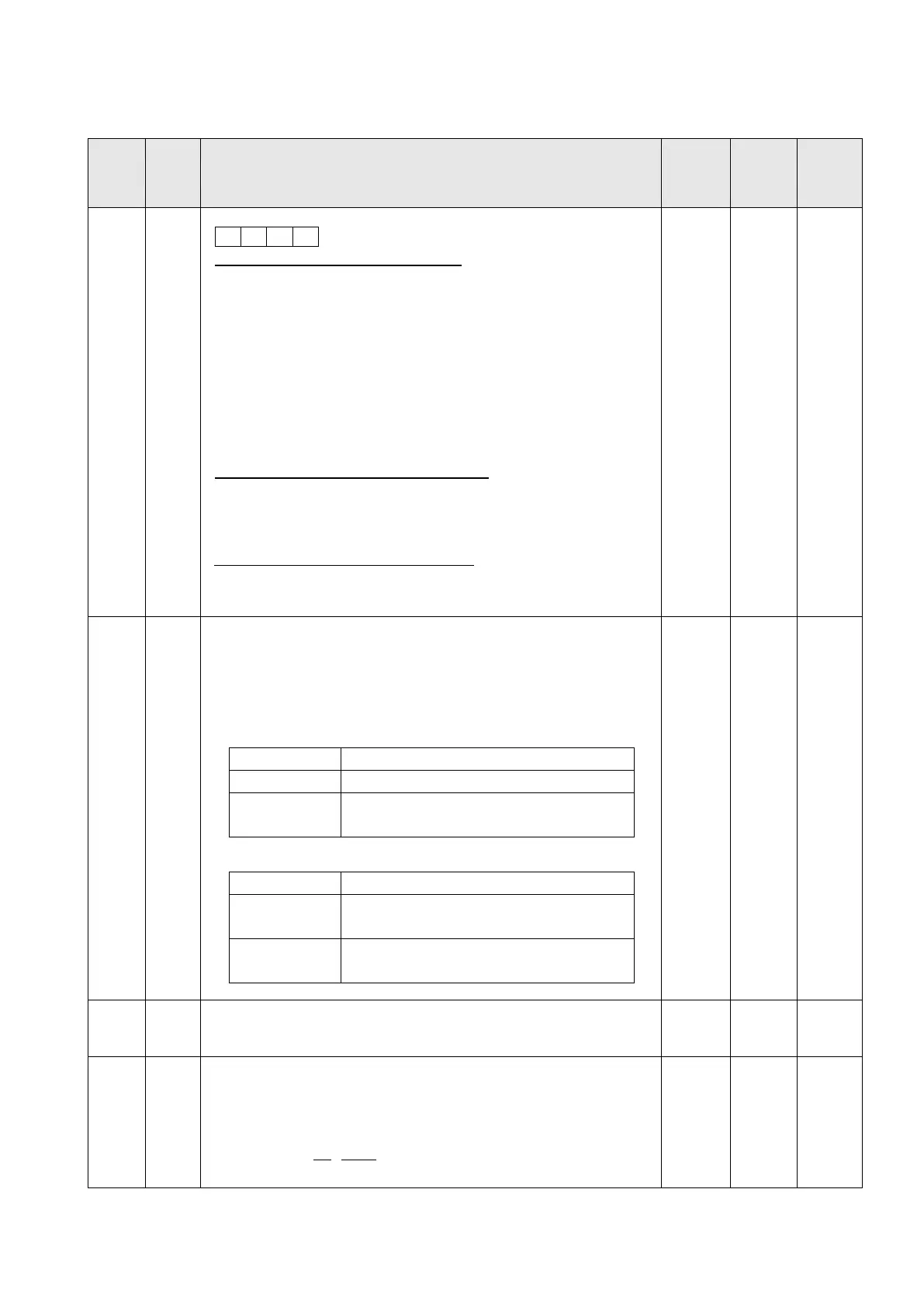

Inner torque limit 1:

Motor generated torque is restricted by this parameter which

unit is %. The generated torque is calculated as below.

Torque limit value = maximum torque *PA05

TL signal is used to select PA05 or analog TLA as limit value.

TL1 signal enables the PC25 to compare with PA05 or TLA.

If the TL1 and SG are open-circuit, the valid torque limit is:

If TLA < PA05, limit value=TLA

If TLA > PA05, limit value=PA05

If the TL1 and SG are short-circuit, the valid torque limit is:

If PC25 < PA05, limit value=PC25

If PC25 > PA05, limit value=PA05

If PC25 < TLA, limit value=PC25

If PC25 > TLA, limit value=TLA

Electronic gear numerator

See section 6.4.4 for more details.

Electronic gear denominator

The improper setting could lead to unexpected fast rotation so

make sure to set them in the state of SERVO OFF.

The proper range setting is:

1 CMX

(electronic gear ratio) 200

50 CDV

Loading...

Loading...