OPERATING INSTRUCTIONS | Bulkscan LMS511 8014829/ZNC5/2017-06-06 | SICK

Subject to change without notice

14

PRODUCT DESCRIPTION

Teach-in

Conveyor belt

Measuring mode

Conveyor belt

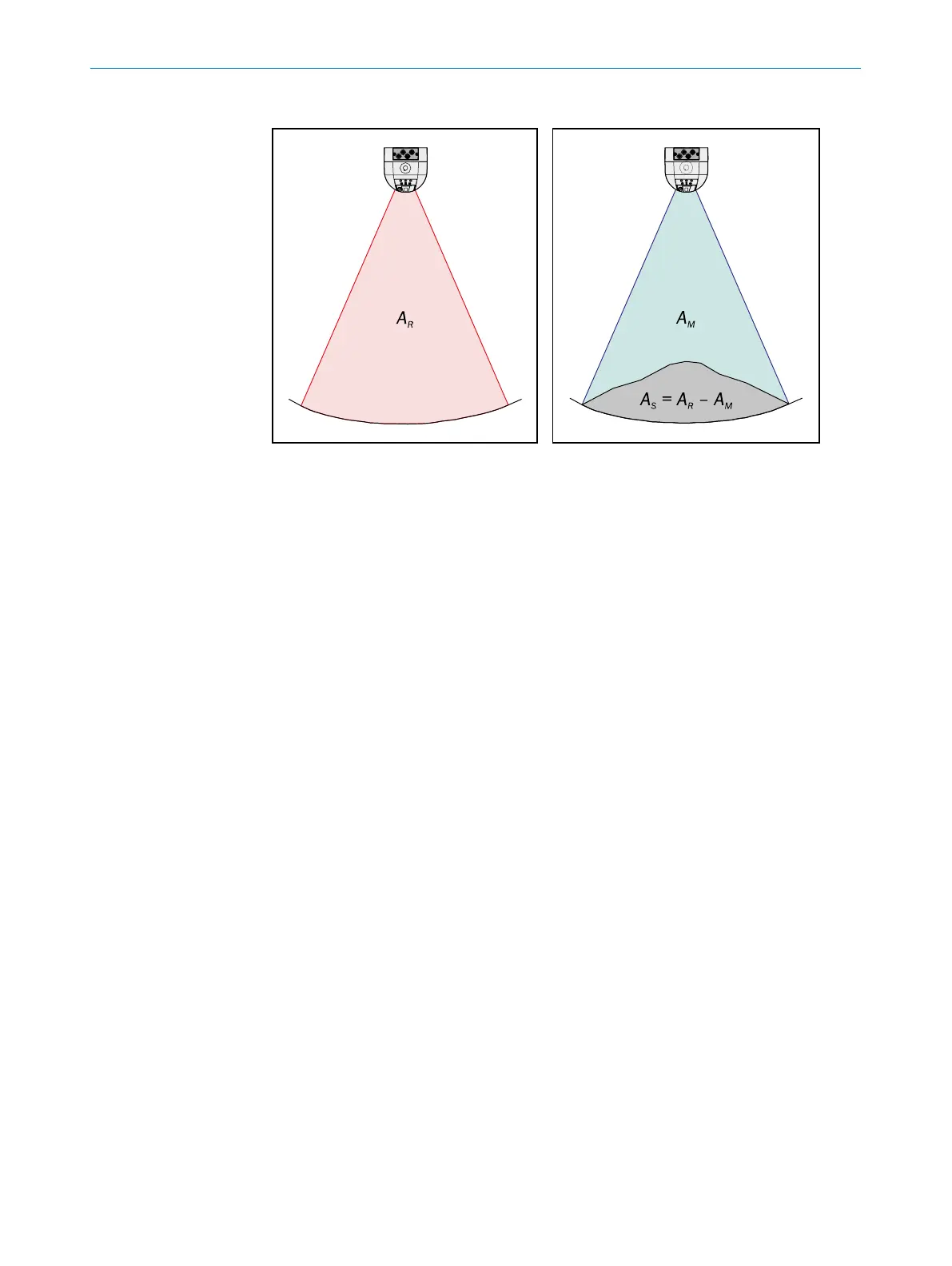

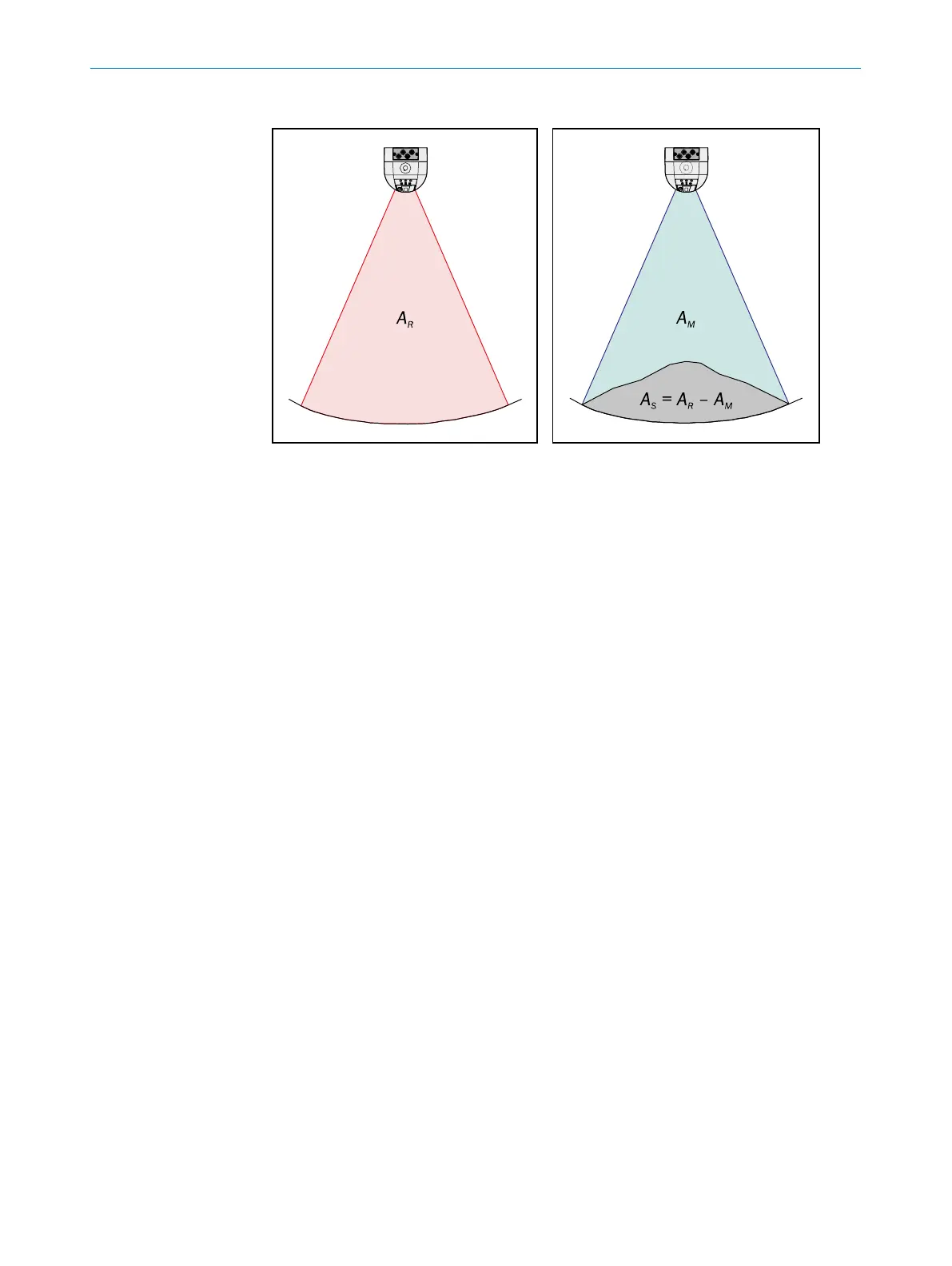

Fig. 2: Measurement principle

A

R

= Reference area

A

M

= Area calculated from the bulkcontour

A

S

= Cross-sectional area of the bulk

Usingthebulkdensity(xedvalueoranalogvalue)andthebeltspeed(xedvalue,

encoder or analog value), the Bulkscan calculates the required output parameters

volumeowrateandmassowrate,aswellasthetotalvolumeandtotalmass.

3.3 Application examples

The Bulkscan is suitable for non-contact continuous detection of the bulk volume on

conveyor belts.

It can be used, for example, in the following areas:

• Monitoring transport systems for conveying coal or ore, e.g., in open-cast mines

or loading plants for:

◦ Minimizing the energy consumption, maximizing the transport performance by

means of maximum loading.

◦ Preventing tilted belts.

• Measuring the ash produced in power stations.

• Checking the loading of transport such as lorries, ships, railway trucks.

• Measuring volume and mass in gravel plants and other operations in the con-

struction industry.

Loading...

Loading...