OPERATING INSTRUCTIONS| Bulkscan LMS5118014829/ZNC5/2017-06-06| SICK

Subject to change without notice

61

COMMISSIONING

8.5 Scan frequency

The scan frequency is the frequency with which the Bulkscan determines and outputs

measured values at the interface.

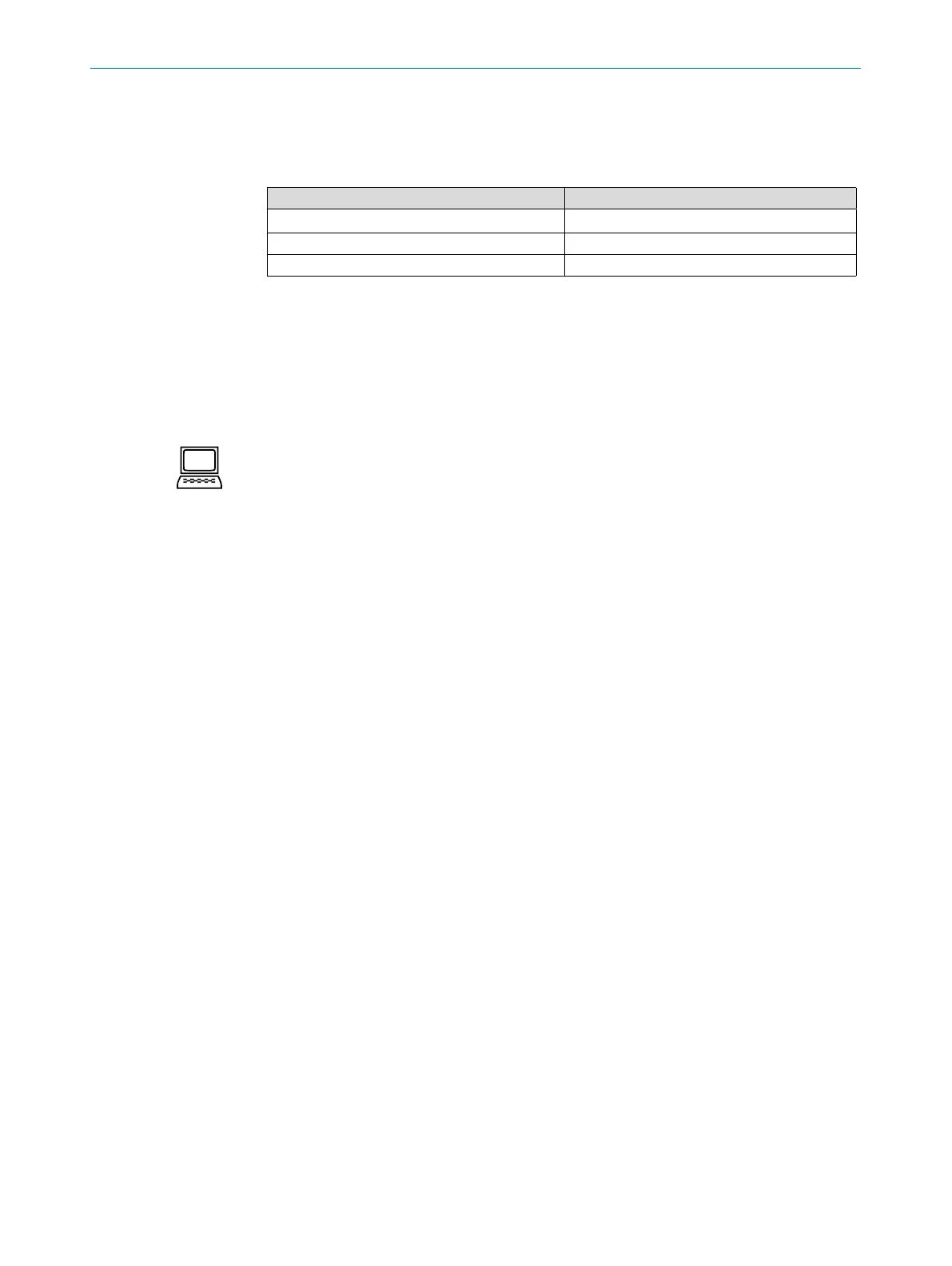

Scan frequency Cycle time

35 Hz 28.6 ms

50 Hz 20.0 ms

75 Hz 13.3 ms

Tab. 15: Congurable scan frequencies

• IfyouconguretheoutputoftheVolume quota or the Mass quota on a digital

output, then make sure that duration of the pause between pulses is longer than

the cycle time resulting from the scan frequency (see "4.13 Digital outputs“ on page

25).

• The selection of the scan frequency affects the energy consumption of the sensor.

System tab, Scan frequency group

8.6 Taking a reference measurement (compensation function)

Depending on the application, systematic errors can occur during the determination of

the volume. In particular the compression of the lower layers of bulk due the mass of

the bulk above will result in reproducible deviations. This systematic error can be calcu-

lated from the volume using a compensation function.

The software calculates this compensation function based on one or more reference

measurements:

• Perform up to 10 reference measurements when the load on the conveyor belt varies

in operation.

• The best results are achieved if the reference measurements cover the entire mea-

suring range, meaning minimum to maximum belt load.

If you replace a sensor, you can also enter the compensation function directly instead

of the reference measurements.

Requirements for the prevention of measurement errors

• Bulk height of the good transported at least 200 mm.

• Constant belt speed during the calibration.

• Constant bulk properties.

• Suitable mounting location and mounting orientation (see "5.2 Selecting the mount-

ing location“ on page 29).

• Deformations of the conveyor belt under load < 5 mm.

Reference volume

For the reference measurement you need a reference volume. To determine the refer-

ence volume, a reference measuring system with an accuracy of ±1% with reference

to the end value of the measuring range is required. Examples for suitable reference

measuring systems:

• Packing plant for the bulk:

• Vessel with straight contours (e.g., container) into which the bulk is transported with

the possibility of subsequently determining the volume.

Note

Note

Loading...

Loading...