OPERATING INSTRUCTIONS| Bulkscan LMS5118014829/ZNC5/2017-06-06| SICK

Subject to change without notice

55

COMMISSIONING

Set the Maximum distance (scan radius):

◦ Enter the distance using the keyboard.

or:

◦ Click and drag the gray distance line to the required radius.

Enter the number of scan cycles over which the sensor is to determine the reference

contour in the Average reference contour overeld.Alargevaluewithaheavilyvi-

brating conveyor belt will result in a better averaged reference contour. The teach-in¬

process takes correspondingly longer.

If necessary, check the Optimization for belts with slits or gaps checkbox (see "8.1.2

Optimization for conveyor belts with slits or gaps“ on page 56).

If required, move the Level compensation slider to compensate for raising or lower-

ing of the conveyor belt (see "8.1.1 Compensation of the conveyor belt level“ on page

55).

Ensure that hazard-free operation is possible

and start the empty conveyor belt.

Click Teach-in. The sensor signals the teaching-in:

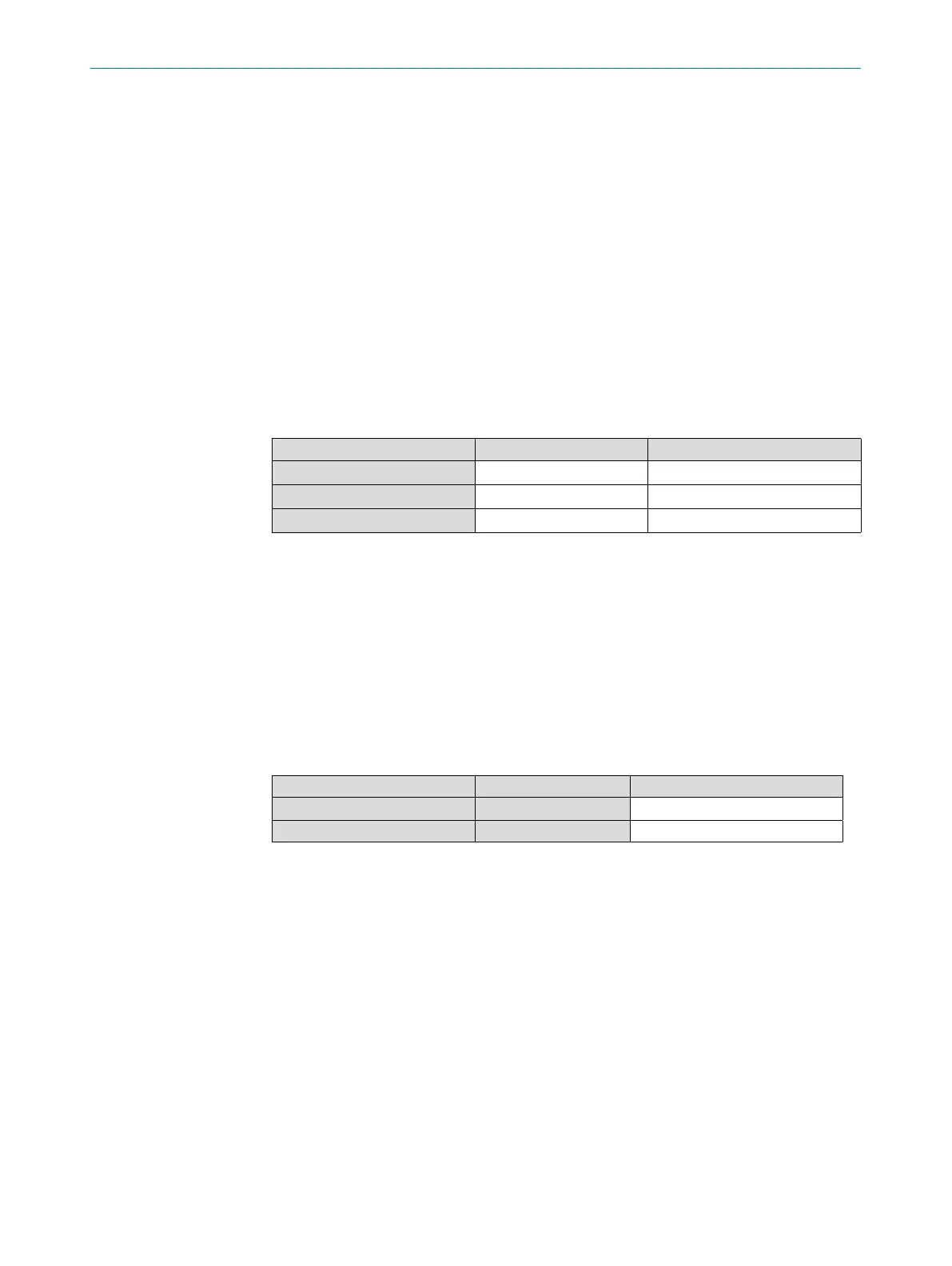

Process LED indication: 7-segment display

During teach-in

Green

(Teach-in)

Following successful teach-in

Green, Orange

(Maintenance)

In the event of an error

Green, Orange

(Maintenance)

Tab. 12: Indicators during teach-in

If the teach-in process was not successful: Check the ambient conditions and/or

adjustthecongurationandrepeattheteach-inprocess.

If the teach-in process was successful: Start the measuring mode.

• The duration of the teach-in process is dependent on the settings selected:

• During the teach-in the sensor will not respond to terminal commands. Terminal

commands sent to the sensor during this time will not be cached.

• Ifyouchangetheapertureangleduringtheconguration,thenthereferencecontour

should be taught-in again for optimization.

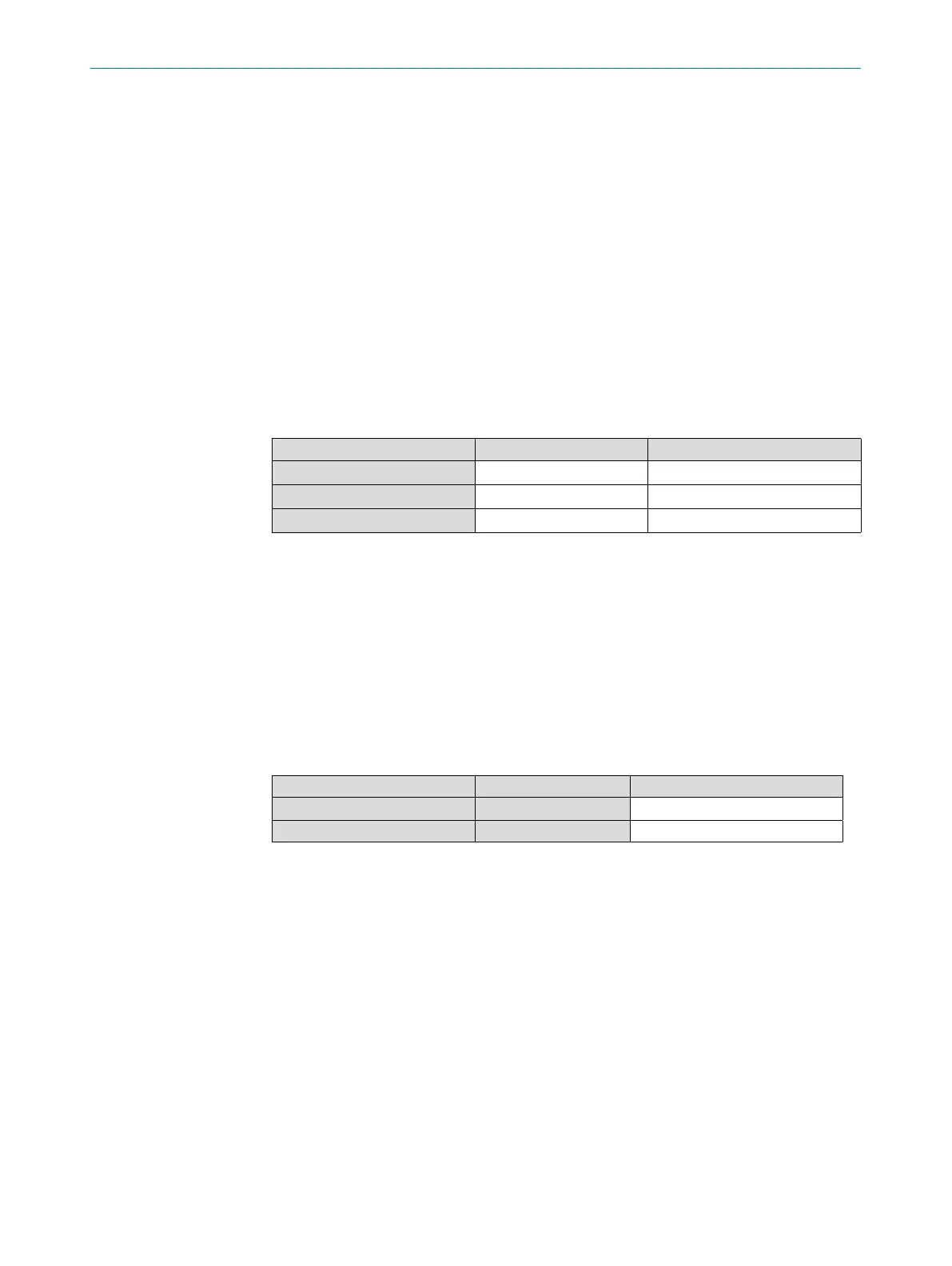

Average reference contour over Scan frequency Duration of the teach-in process

100 cycles 75 Hz 100 ÷ 75 Hz = 1,3 s

10,000 cycles 35 Hz 10.000 ÷ 35 Hz = 286 s

Tab. 13: Examples of the duration of the teach-in process

8.1.1 Compensation of the conveyor belt level

Due to the weight of the bulk the conveyor belt may drop or may lift:

• Conveyor belt dropping: Due to the weight of the bulk, the conveyor belt may drop

between transport rollers.

• Conveyor belt lifting: Due to the weight of the bulk, the tension on the conveyor belt

on the neighboring transport roller sections may be increased and as a result the

conveyor belt may lift.

Note

Loading...

Loading...