18 FLOWSIC500 · Operating Instructions · 8025733/1GMJ/V4-2/2022-07 · © SICK Engineering GmbH

Product description

Subject to change without notice

2.1 Measuring principle

2.1.1 Gas flow meter

The FLOWSIC500 works according to the principle of ultrasonic transit time difference

measurement.

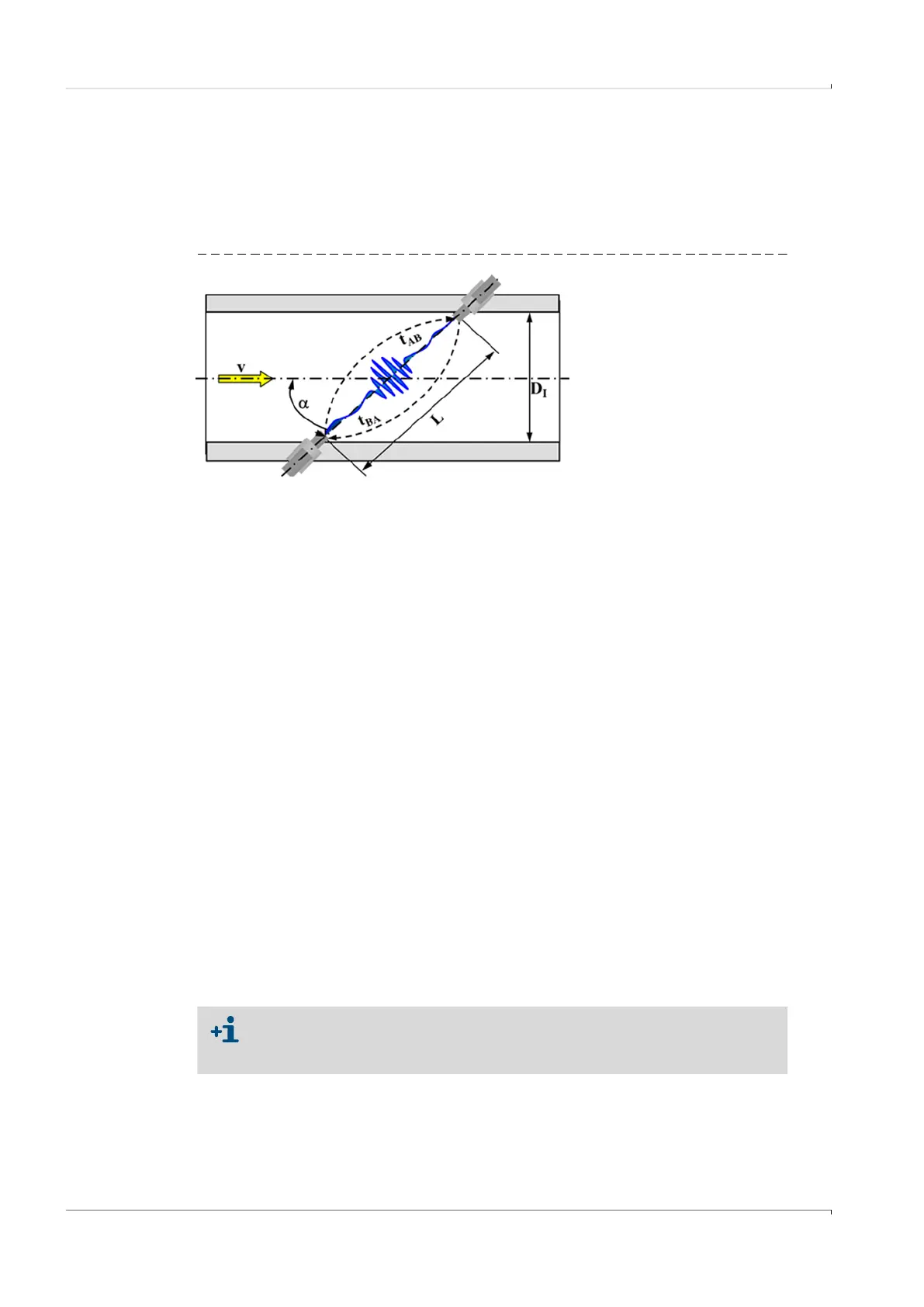

Fig. 2 Functional principle

Measured signal transit times t

AB

and t

BA

are defined by the current sound and gas velocity.

Gas velocity v is determined from the difference between the signal transit times. Therefore

changes in the sound velocity caused by pressure or temperature fluctuations do not affect

the calculated gas velocity with this measurement method.

The FLOWSIC500 calculates the volume flow rate internally from the gas velocity and the

diameter of the measuring section of the gas flow meter.

2.1.2 Volume conversion (optional)

The integrated volume conversion converts the measured gas volume from measurement

conditions to base conditions.

Calculation according to EN 12405:

The measurement conditions are either determined with pressure and temperature

sensors or entered as fixed value.

v = Gas velocity

L = Measuring path

= Angle of inclination in °

t

AB

= Sound transit time

in flow direction

t

BA

= Sound transit time

against flow direction

D

I

= Pipe inner diameter

Q = Volume flow

The following short forms are used in this document for better readability:

● Volume at base conditions = base volume

● Volume at flowing conditions = measurement volume

Q

4

---

D

I

2

L

2 cos

----------------

t

BA

t

AB

–

t

AB

t

BA

----------------------

=

V

b

C V

m

=

V

b

= Volume at base conditions

C = Conversion factor

V

m

= Volume at measurement conditions

p = Gas pressure at measurement conditions

p

b

= Pressure at base conditions

T = Gas temperature at measurement conditions

T

b

= Temperature at base conditions

Z

b

= Compression factor at base conditions

Z = Compression factor at measurement conditions

C

p

p

b

-----

T

b

T

------

Z

b

Z

------

=

Loading...

Loading...