Product description

FLOWSIC500 · Operating Instructions · 8025733/1GMJ/V4-2/2022-07 · © SICK Engineering GmbH 31

Subject to change without notice

2.8 Parameter protection

2.8.1 Parameter locking switch

A parameter locking switch is located on the circuit board to secure the custody relevant

parameters. This covers all values that influence volume metering and volume conversion.

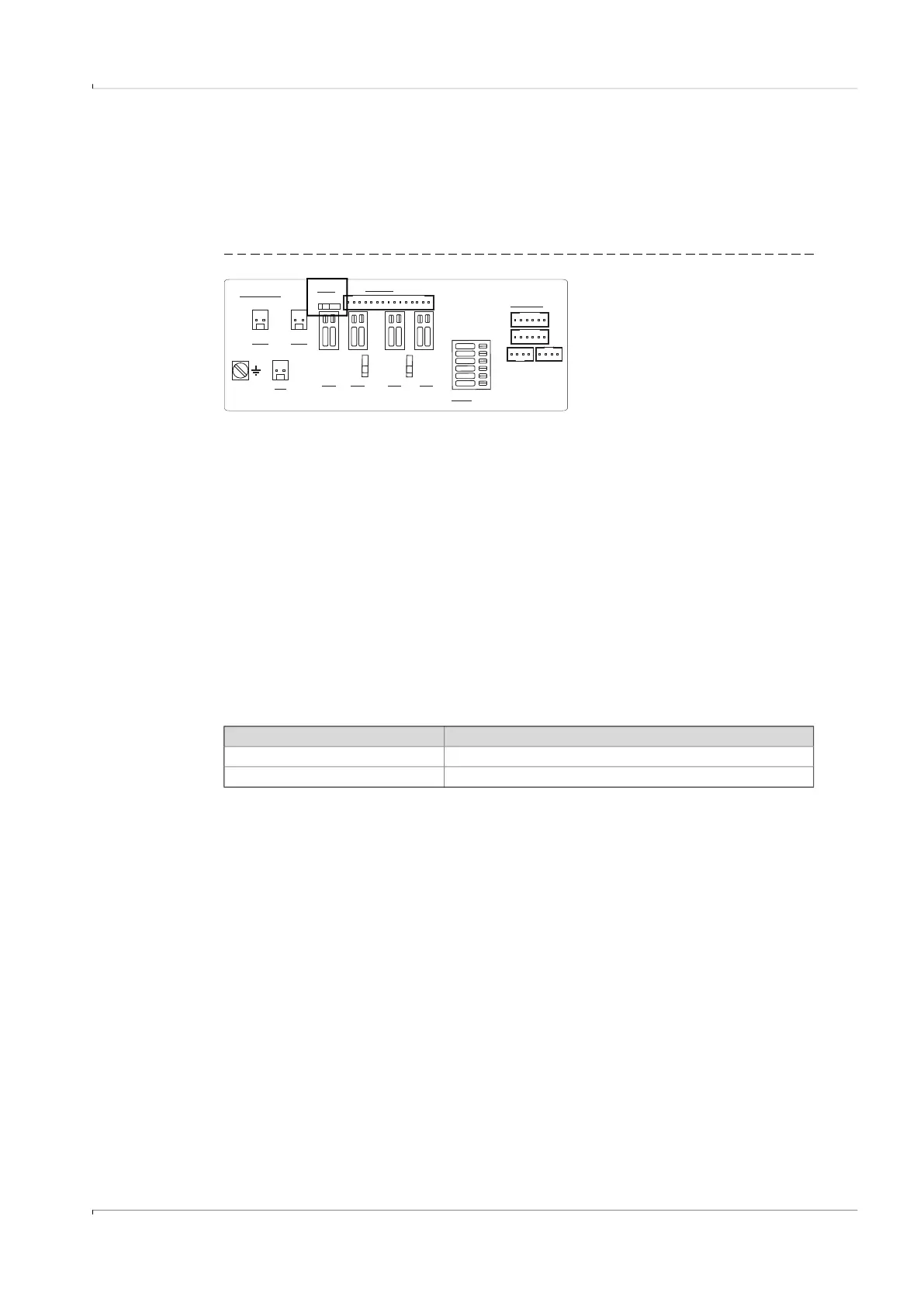

Fig. 7 Parameter locking switch on the circuit board

The parameter locking switch is secured by the terminal compartment cover and a seal.

2.8.2 Metrology logbook

Selected custody relevant parameters can be modified when the parameter locking switch

is closed and after logging in as authorized user.

An entry in the metrology logbook is generated to ensure the traceability of these

parameter changes. The entry contains the timestamp, old and new value, totalizer level V

(for gas flow meters) or Vb (for gas flow meters with device option volume conversion) and

the logged on user.

The Metrology logbook can have a maximum of 100 entries. The FLOWSIC500 switches to

status “Warning” when the Metrology logbook is full.

The Metrology logbook can be cleared when the parameter locking switch is open.

Parameter changes to the following parameters are entered in the Metrology logbook as

long as entries are possible.

EXT. POWER

BAT1

N.c.

DO3

DO0

+-

RS485

*

-

+

-

+

A

B

P1

P2

T1

T2

SENSORS

DISPLAY

LOCK

OFF ON

5..12V

NAMUR

4,5..16V

1.5 mm²

(AWG 16)

W

R :100

S

2..16V

2..16V

4074419

DO2

*Optional

V see module

CC

.

OC

NAM

UR

2..16V

DO1

+-

BAT2

+-

+-

OC

NAM

UR

+- +-

Table 5 Custody relevant parameters - gas flow meter

Parameter Description

Max. reverse flow volume Buffer volume for reverse flow

Symbols for measured value displays Symbols used on the display (formula symbols)

Loading...

Loading...