24 FLOWSIC500 · Operating Instructions · 8025733/1GMJ/V4-2/2022-07 · © SICK Engineering GmbH

Product description

Subject to change without notice

2.4.4 Optical data interface

An optical interface according to IEC 62056-21 with serial bit, asynchronous data

transmission is located on the front of the FLOWSIC500.

The interface can be used to read out data and parameter settings and to configure the

FLOWSIC500.

2.5 Totalizers

2.5.1 Device status and totalizers used

Various volume totalizers are fitted on the FLOWSIC500 depending on the configuration.

Meter V is used in the configuration as gas flow meter. If the gas flow meter has a

malfunction, the measured volume is also recorded in the error volume counter errV.

A gas flow meter Vm, a base volume meter Vb and a total volume meter Vbtot are used in

the configuration as gas flow meter with integrated volume conversion (device option). If

malfunctions occur, the measured values are not recorded in the base volume meter Vb,

but the converted volume is recorded in the malfunction volume encoder totalizer errVb.

Authorized users (user level “Authorized user”) can reset the error volume counters → p. 98,

§5.2.11.

2.5.2 Reverse flow

The FLOWSIC500 is designed as unidirectional and has a configurable zero-flow cutoff

which is factory set to a value of 1 m

3

(35 ft

3

) as default.

The totalizers are stopped during reverse flow and this volume is counted in a separate

buffer totalizer. When normal operation resumes, the buffer totalizer is first computed with

the flow rate.

The totalizers are first incremented again after the reverse flow volume has passed

through.

During reverse flow, the meter first switches to malfunction when the preconfigured buffer

volume has been exceeded. An error message is output on the device.

The zero-flow cutoff (measuring threshold for low flow rate) and the buffer volume (limit

value for reverse flow volume) can be adjusted with the FLOWgate

TM

operating software

during commissioning (→ p. 73, §4.3.2.3) or, after commissioning, in the “Warning” area in

the “Parameter Modification” menu.

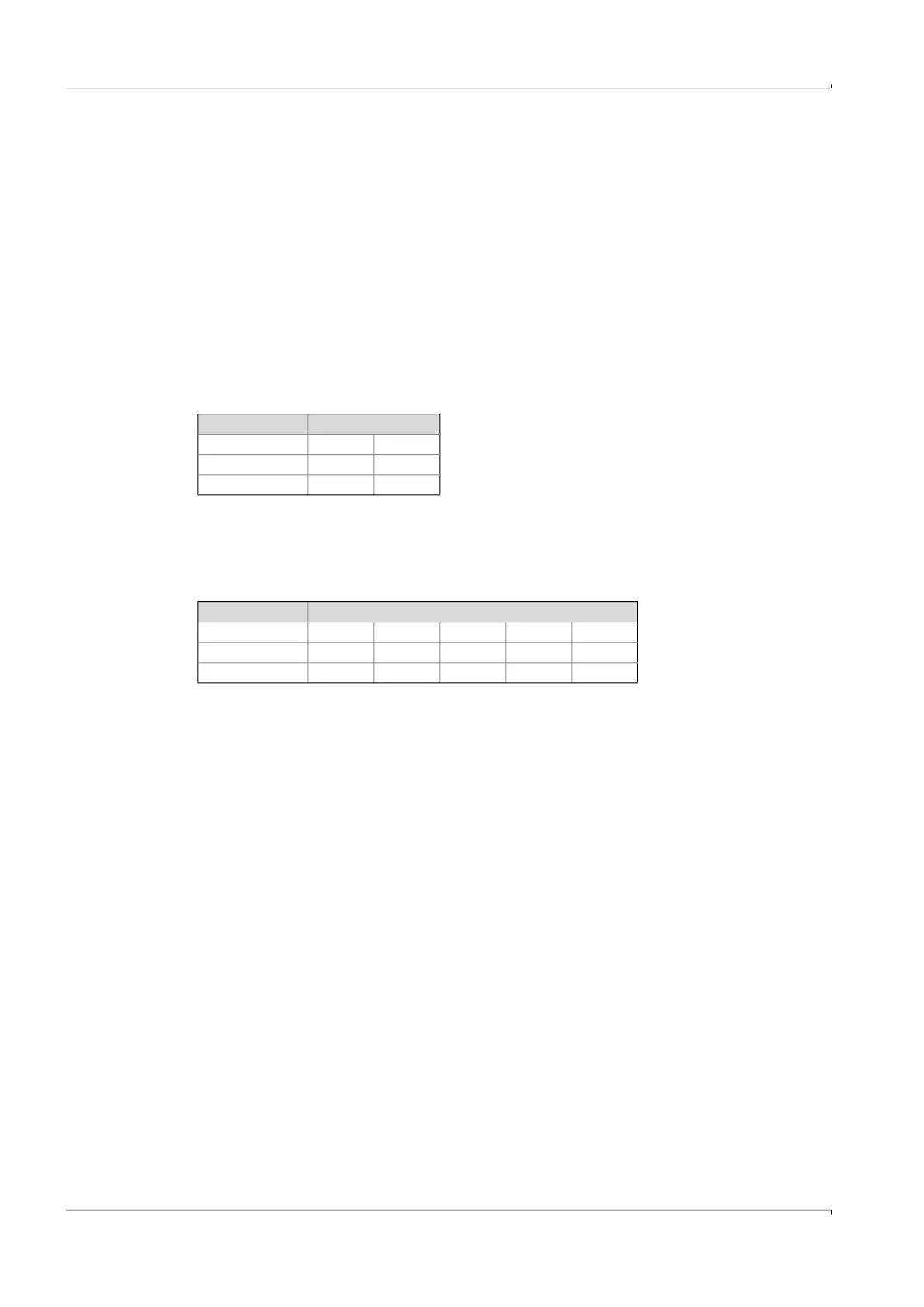

Table 2 Device status and totalizers used

Status Totalizer

V errV

Operation

●

Malfunction

● ●

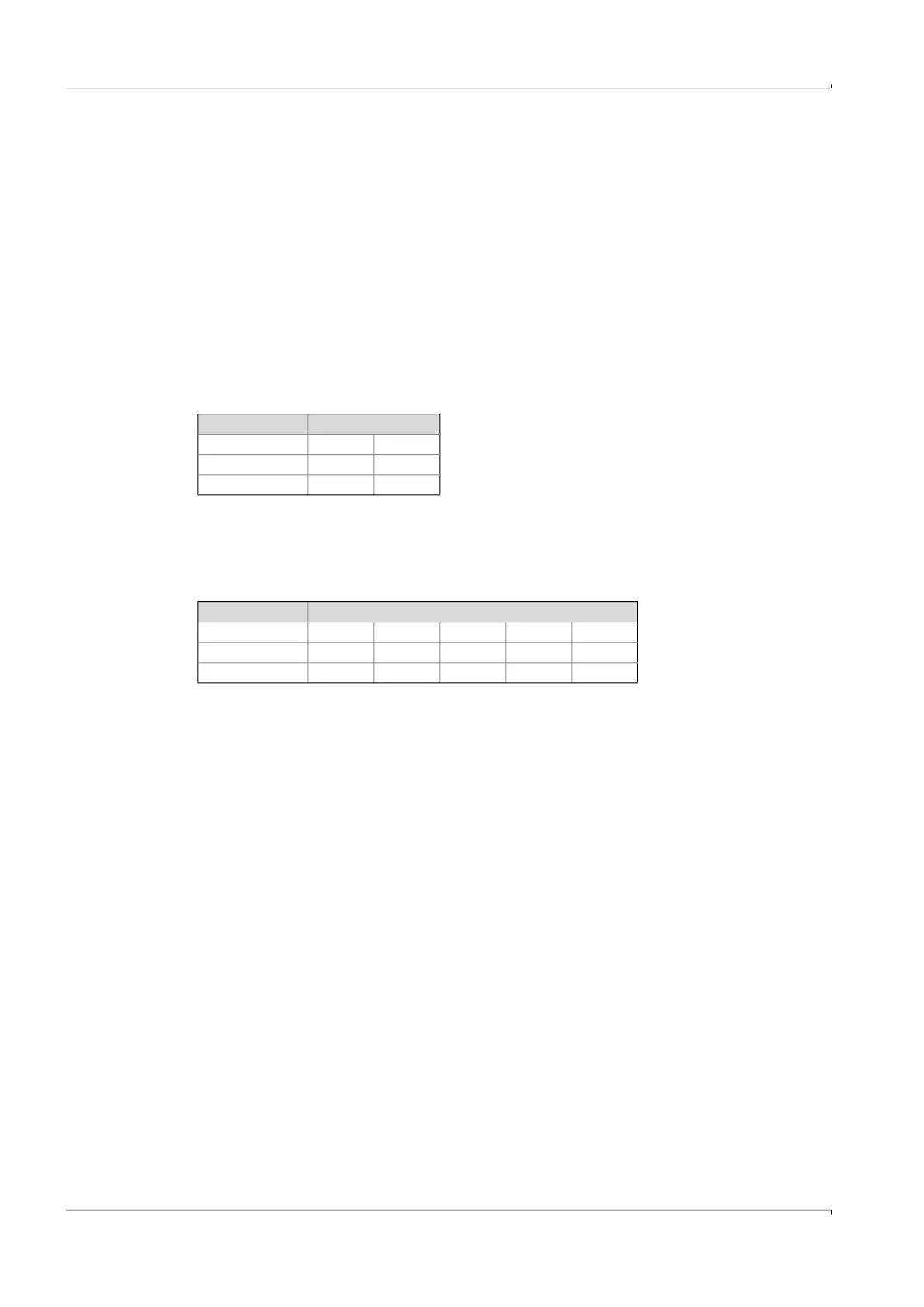

Table 3 Device status and totalizers used (with device option volume conversion)

Status Totalizer

Vb errVb Vbtot Vm errVm

Operation

● ● ●

Malfunction

● ● ● ●

Loading...

Loading...