5-10

1010GCNFM-3C

Section 5

17. Return to the menu, and press to finish the transducer install routine.

5.4 USING 1012T MOUNTING TRACKS

The 1012TP and 1012THP Mounting Tracks provide a rigid mounting platform for Series 1011 universal

or high precision size A or B transducers. The mounting tracks service pipe sizes up to a maximum of

5.00” (140 mm) outer diameter. Operating temperatures are supported up to 250°F (121°C). The as-

sembly consists of lightweight aluminum track rails with integral transducer clamping screws. Attached

index pins enable positive locating of the transducers at fixed spacing locations. Roller-chains and ten-

sion screws secure the assembly to the pipe. The following instructions refer to 1011 universal transduc-

ers. Please refer to Engineering Drawing 1012THP-7A for reflect mounting of high precision transducers

and 1012THP-7B for direct mounting of high precision transducers.

The 1012T mounting tracks support both Direct and Reflect mounting modes. The flow computer recom-

mends the appropriate transducers, mounting track and mounting mode, based on the pipe data en-

tries. Refer to the instructions in paragraph 4.4 for details on the Transducer Installation procedure. If

necessary, review paragraphs 5.1.2 through 5.1.4 for details on how to select and prepare a mounting

location on your pipe.

Installing a 1012T Mounting Track in Reflect Mode

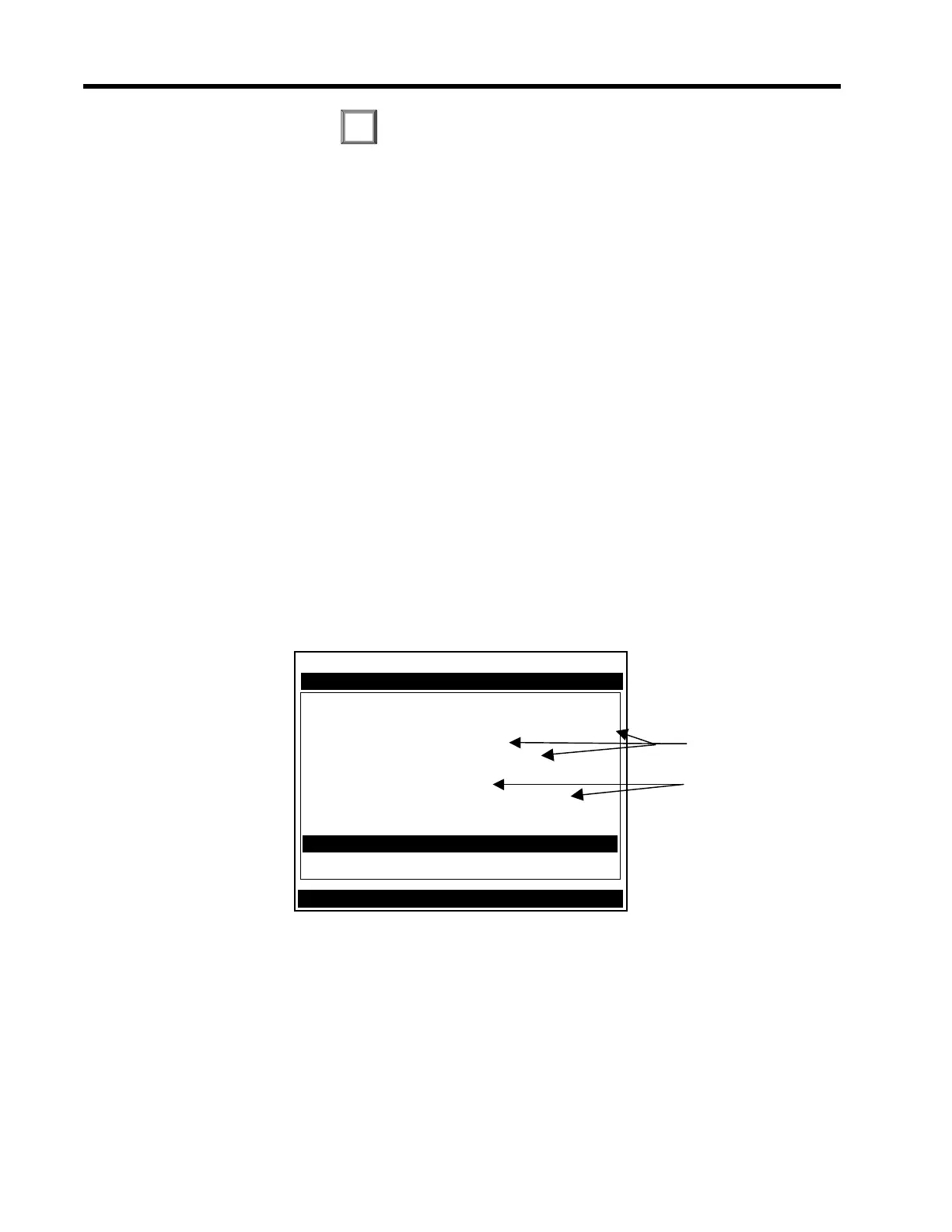

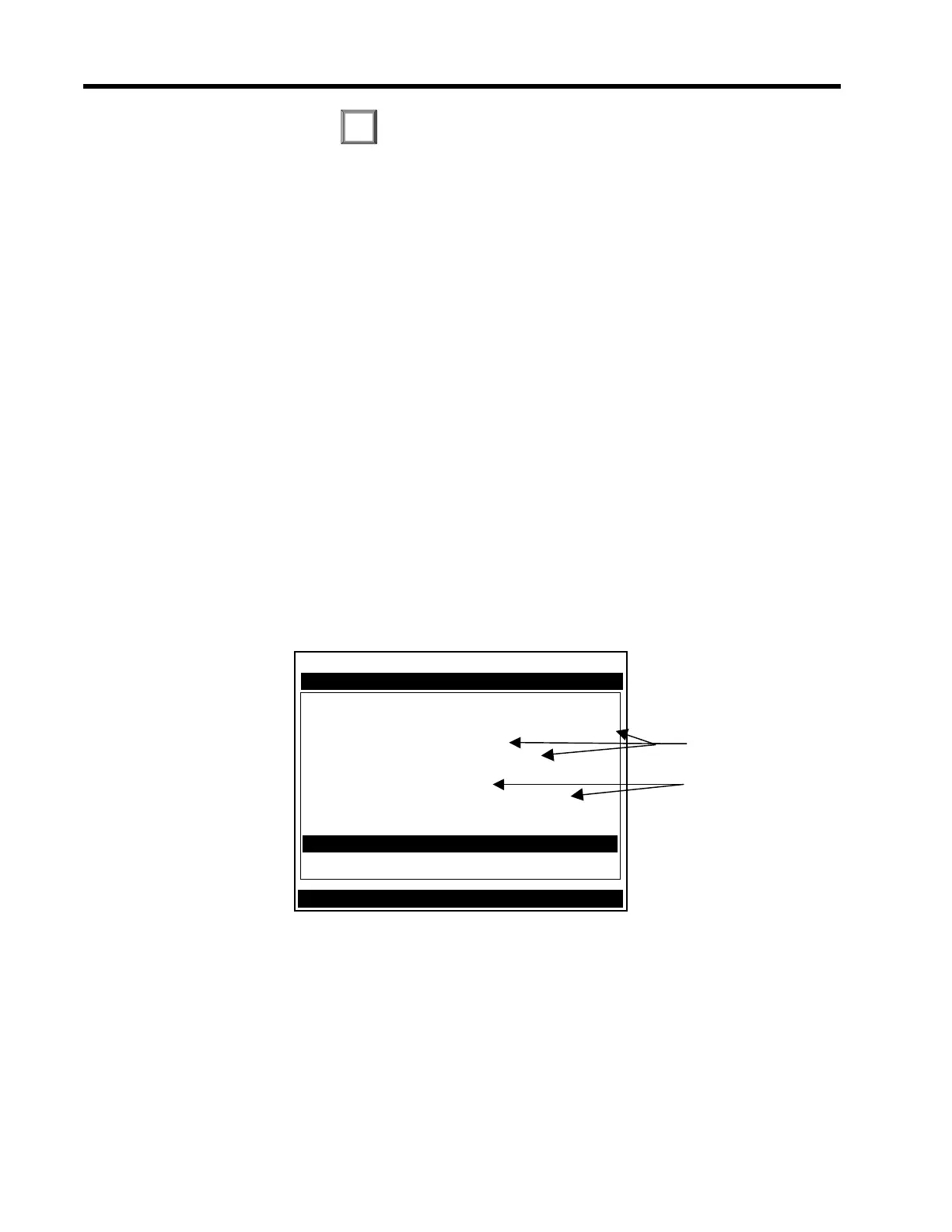

Paragraph 4.4 describes the Transducer Installation procedures that lead up to the automatic selection of

transducers, mounting mode and spacing method. Examine the figure below, which shows a typical

Pick/Install Xdcr menu screen. Note the automatic assignment of model numbers for the transducer and

mounting track, plus the designation of the number index.

This example requires a Model 1012T Mounting Track to accommodate size B3 universal transducers.

Note the reported number index. You will be inserting an index pin into this hole on the track rail to

position one of the transducers (see diagram on next page).

1. Perform all required menu steps up until the point where you respond to the [Install Completed?]

prompt. Note the reported number index. You will be inserting index pins into this hole and the

reference hole on the track rail (see diagram on next page). Check to ensure that you have a matched

set of transducers. They both should have the same S/N number but marked with either an “A” or “B”

(e.g., 100A and 100B).

ENT

Note selection of

type, size and

mounting mode.

Note selection of

mounting track part

number and number

index.

Controlotron Dual Path SITE1

Key [Install] after mounting transducers

Pick/Install Xdcr

Path Select 1

Transducer Model 1011G Universal

Transducer Size B3

Xdcr Mount Mode Reflect

Spacing Offset Minimum

Number Index 6

Spacing Method Track 1012TP

Ltn Value (in) 0.581

Install Completed? No

Zero Flow Adjust Channel Not Setup

Loading...

Loading...